Using Couponing to Test High-Risk Microfluidic Consumable Features and Reduce Time to Market

The success of your new IVD product takes more than a great idea and its adaptation to your end-users’ needs. In part one of this series, we covered the importance of beginning with your end-user’s experience in mind, however, in order for an innovative device to be positively received by the market, it’s development must also reflect a deep understanding of the product’s critical features, their relative risks, and their optimal functioning state.

How can your team raise its level of understanding of these myriad factors in a time and cost-efficient way? They can do it by separately testing the highest-risk elements that are essential to product function—a process called “couponing.”

What is a Coupon?

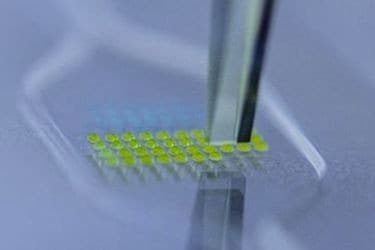

Essentially, a coupon is a small part of a subsystem to be tested as a stand-alone unit. Coupons are selected then isolated for testing based on a thorough analysis of product functionality and risk. The high-risk features—those individual components which tend to drive the overall product’s performance—are developed concurrently and then integrated. To minimize development time after integration, couponing allows for the rigorous individual evaluation of the separate parts (especially those based on innovative approaches) so that vulnerabilities are identified and addressed at the earliest stage possible.

How Do We Decide to Make a Coupon?

For products of low to moderate complexity, we may test the product as a whole, or test one to two subsystems simultaneously in a coupon. If the IVD developer has extensive experience with a particular technology, even moderate to high-complexity products may not need couponing. This is particularly true if they are refinements to prior models on which the interdependencies of components are well understood and documented.

If the product involves new geometries that have never been tested, then couponing adds immense value to a project’s timeline and functional success. It provides an opportunity to break out a smaller specific area of study for in-depth evaluation.

Know our expertise in microfluidic development

Couponing and Risk Mitigation

Couponing reduces technical and performance risk by identifying the high-risk features necessary for product functionality. These are concurrently developed with their own manual assembly and breadboarding systems, all of which are integrated into the final product. This method allows for integrative testing of all four critical aspects of an IVD product: the disposable, the instrument or reader, the manufacturing line, and the assay chemistry.

As a risk-mitigation technique, couponing is designed to hold constant the routine elements of a product’s design—those in which performance is well understood or noncritical—while isolating the novel elements in which innovation introduces new risks and expected benefits.

How is a Coupon Made?

During the conceptual phase of development, engineers sketch or use CAD to outline how the product will meet requirements and identify the critical features necessary for product functionality.

These critical feature concepts are also evaluated against:

- Cost of goods (COGs)

- Considerations of Design for X (or DFX, the evaluation for manufacturing/assembly, usability and use contexts, interfacing, and more)

- Instrument complexity

- User needs

- Use contexts

A subsequent risk assessment is performed using the same criteria. The features with the highest risks become the primary focus of development and, therefore, testing. These crucial elements must succeed individually and seamlessly integrate with the other, lower-risk features in the final product. Often, couponing can shorten and reduce the cost of development time. Couponing is intended to mitigate risk without delaying launch readiness. Instead of designing and testing a full system requiring multiple iterations and chasing errors in a large complex system, couponing isolates the critical features into relevant testable chunks that can be quickly iterated for significantly lower cost. Then, during integration of each coupon into the full device, we understand the system to resolve errors faster.

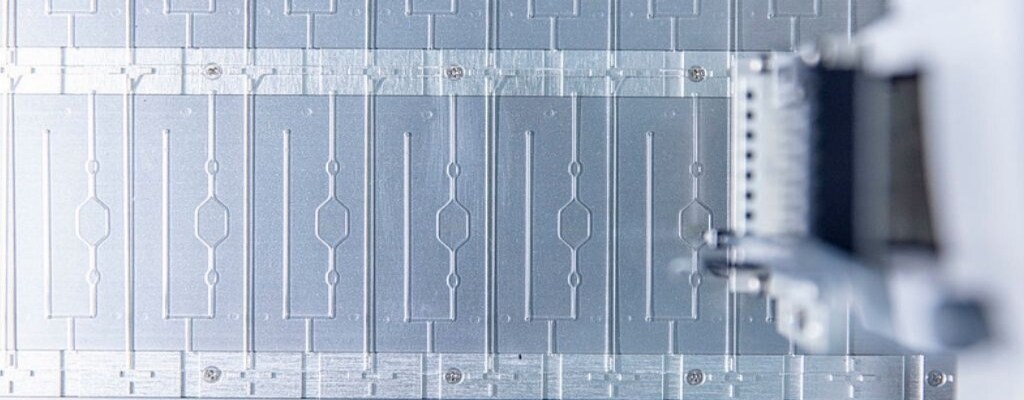

Coupons can be created through rapid prototyping methods such as:

- Laser Cutting, Etching, or Welding: The versatility, precision, and cost effectiveness of this method makes it ideal for the rapid production of coupons for testing when it is appropriate to the material (e.g., metal)

- CNC Machining: This enables high-precision metal components used in fixture development and molding components

- 3D Printing: Because of its cost effectiveness and rapid turnaround from design to production, 3D printing can be very helpful for products in which a larger quantity of coupons are needed. Typically used for plastic components, it enables efficiency when multiple iterations of testing are expected, perhaps under a variety of conditions

- Plastic Injection Molding: This process provides a glimpse of a product in its nearly finalized state prior to transfer to full-scale manufacturing. Benefits include the use of multiple plastics, production of enhanced-strength coupons, and integration of detailed features or complex geometry, as needed.

- Assembly using manual fixtures to aid in alignment and throughput, or on-site specialized equipment such as laser welding, ultrasonic welding, UV curing, and heat staking.

Beyond Couponing: What are the Next Steps?

The couponing process is used for a wide variety of products. Some cutting-edge or esoteric inventions require going beyond this approach for better ways to achieve the same ends, as do applications whose coupon testing plans might otherwise be too time-consuming or wasteful of costly raw materials.

These logical extensions of the couponing process allow for in-depth evaluation of the risks and benefits of a wide variety of product innovations, including unique materials, technologies, and design geometries. While couponing achieves significant risk management with limited time and materials, virtual couponing can bring those efficiencies to the next level.

Conclusion

As you move your pipeline of products towards the market, consider the use of couponing in the development plan and work with a highly experienced partner with the staff and facilities to carry it out. Our engineers are experienced experts in the couponing process and we have built a large repertoire of manufacturing capabilities and testing know-how.