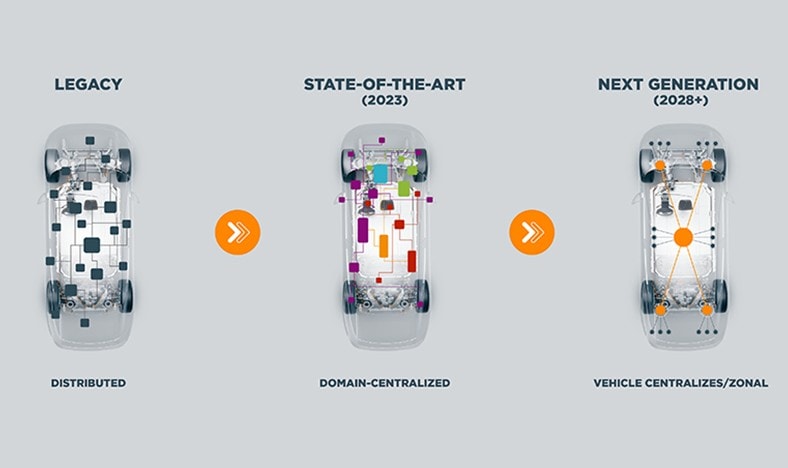

The shift to smarter E/E architectures will reorganize and simplify the wire harnesses to support more efficient, higher-speed transmission and real-time processing of vastly more sensor and environmental data. The objective is fewer nodes/ECUs but significantly more connection opportunities (ports) per node – linked together by a high-speed data backbone.

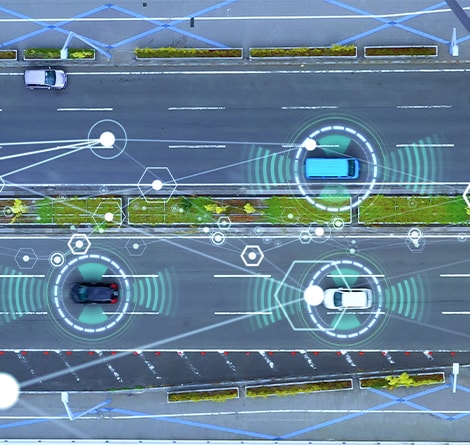

Over the next five years, zonal E/E architectures will further consolidate the number of port-dense nodes by connecting diverse but co-located vehicle functions to nearby zone controllers or gateways that, in turn, link to HPCs. The communication within this zonal architecture resembles a computer network, utilizing highspeed Ethernet (10 Gbps) data rates for interzonal communication between the vehicle’s central processing units and the zonal executives.

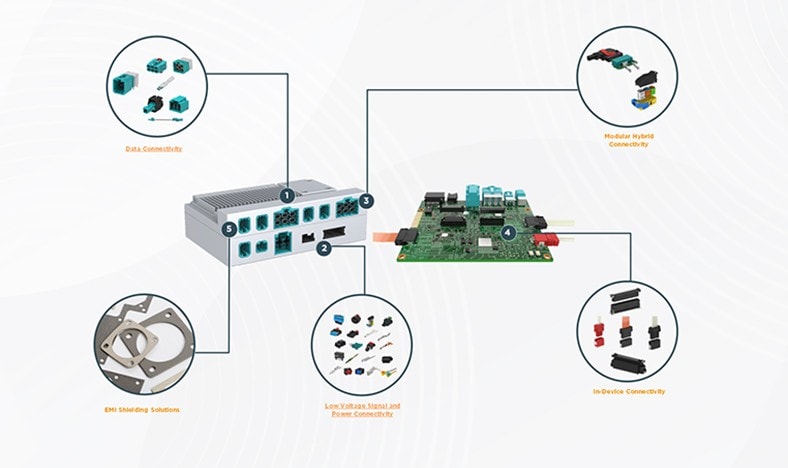

At TE Connectivity, our mission is to ensure that tomorrow’s connectivity is faster, more secure, more reliable – and able to handle the exploding volumes of data and signals. Our connectivity solutions are not only smarter and smaller than ever, they’re also better at multi-tasking, such as transmitting signals and power alongside high-speed data. And they’ve been designed from the start with automation readiness and sustainability in mind.

Key to this shift are smarter E/E architectures that reorganize and simplify the wire harnesses to support more efficient, higher-speed transmission and real-time processing of vastly more sensor and environmental data. The objective is fewer nodes/ECUs but significantly more connection opportunities (ports) per node – linked together by a high-speed data backbone.

EE ARCHITECTURE PRODUCTS

With an extensive range of cutting-edge automotive connectivity products and technologies, TE is your one-stop partner for data, signal, and power connectivity solutions that improve the modularity, flexibility, and functionality of vehicle systems to meet the need of zonal and next-generation E/E architectures.

‘Zonal’ next-generation architectures will have significant implications for vehicle manufacturing. As zone-based installation approaches replace unwieldy, vehicle-spanning harnesses, it becomes possible to use lighter cabling systems, which enhance electrical efficiency, reduce weight and simplify harness installation and, due to better partitioning, automated harness production becomes an option.

EE ARCHITECTURE APPLICATIONS

EE ARCHITECTURE INSIGHTS

Trend Paper: Connectivity Solu

Download Now

The automotive industry is rapidly evolving, driven by demands for personalization, connectivity, and sustainability. This trend paper reveals how advanced zonal E/E architectures simplify wiring, reduce weight, and enable smarter, future-ready vehicles.

Enabling Superior Mobility Exp

Download Now

The thrill of powerful engines is fading. In its stead are: personalization and the ability to integrate consumers’ digital lives into the mobility experience; autonomous and automated features for greater safety and comfort; constant connectivity to everybody and everything; electrification; and su

Electromagnetic Compatibility

Download Now

Electromagnetic interference (EMI), also known as radio frequency interference (RFI), is when an outside source causes noise or interference in an electrical path or circuit.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e