As drones and UAVs become increasingly central to commercial, industrial, and defense operations, the electromagnetic environment in which they operate grows more complex. Electromagnetic interference (EMI) can compromise mission-critical systems, degrade performance, and pose safety risks. This whitepaper explores the technical, operational, and strategic importance of EMI shielding in UAVs and outlines how TE Connectivity’s Performance Materials delivers advanced, integrated solutions to mitigate these challenges EMI in UAV systems can originate from both internal and external sources. Internally, components such as electronic speed controllers (ESCs), brushless motors, switching regulators, and RF modules generate interference.

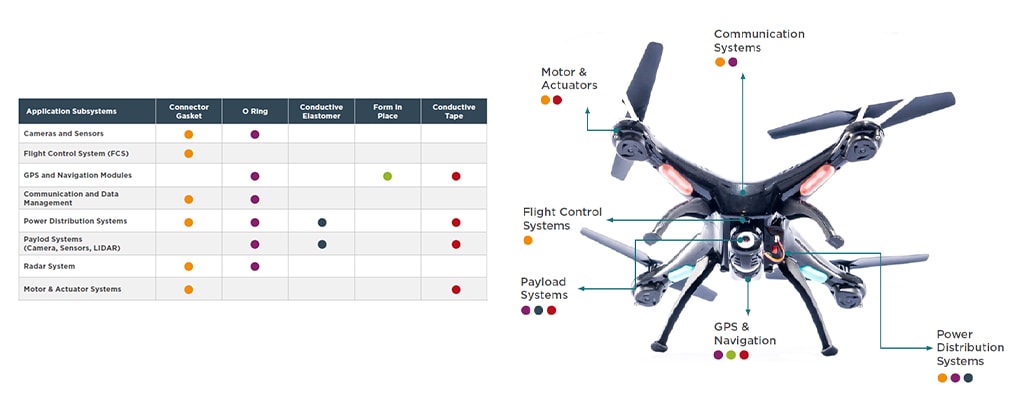

Drone Subsystems EMI Design Considerations

EMI in UAV systems can originate from both internal and external sources. Internally, components such as electronic speed controllers (ESCs), brushless motors, switching regulators, and RF modules generate interference. Externally, ground radar, satellite links, nearby drones, and 5G towers contribute to the EMI landscape. Subsystems vulnerable to EMI include GNSS/GPS receivers, flight control units (FCUs), telemetry and video links, and sensor arrays such as LiDAR, infrared, and multispectral sensors. The consequences of EMI range from loss of control and navigation errors to data corruption, reduced mission reliability, and safety hazards.

Unmanned Aerial Vehicles (UAVs) integrate multiple electronic subsystems—flight control, navigation, communication, power distribution, and payload systems—that are highly susceptible to electromagnetic interference (EMI). Effective EMI shielding is critical to ensure signal integrity, operational reliability, and compliance with regulatory standards.

Flight Control System (FCS)

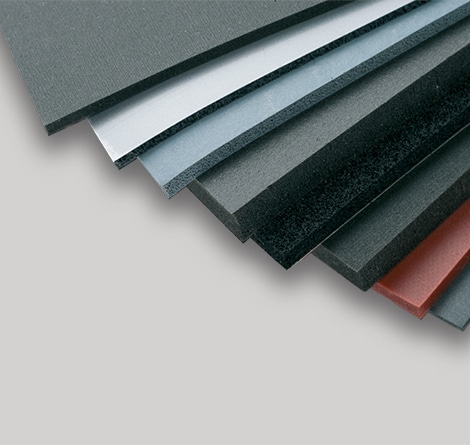

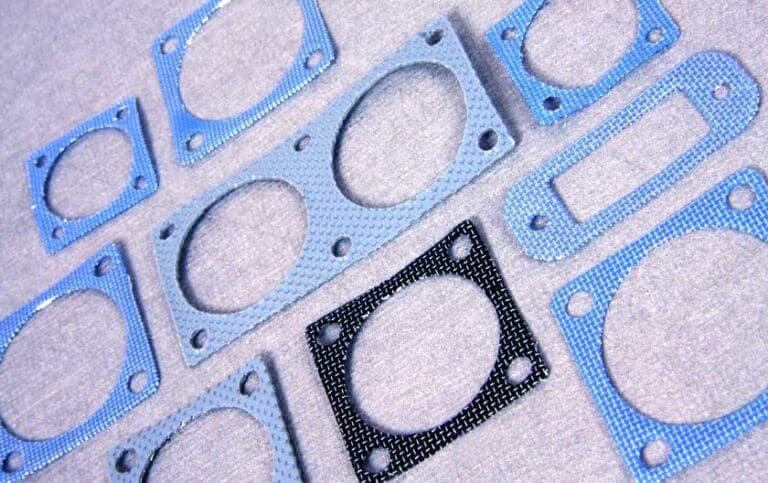

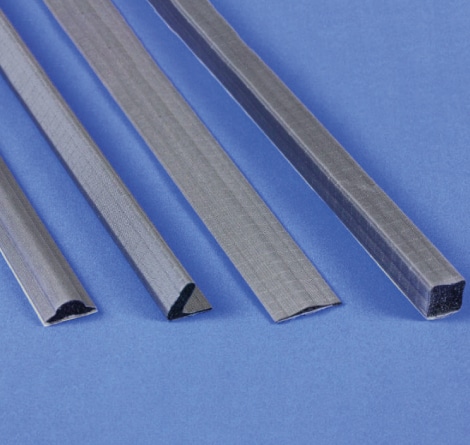

The Flight Control System (FCS) is one of the most critical UAV subsystems, housing sensitive microcontrollers and inertial measurement units (IMUs) that are highly vulnerable to electromagnetic interference (EMI) from motors and RF systems. To mitigate these risks, conductive elastomers are often used because they provide exceptional shielding effectiveness—up to 120 dB (Based on internal testing under controlled conditions)—while also offering environmental sealing against dust and moisture. Additionally, connector gaskets are applied at interface points to prevent EMI leakage through connectors. Together, these solutions maintain signal integrity for stable flight performance and ensure long-term protection against environmental contaminants.

GPS & Navigation Modules

The GPS and navigation modules are particularly vulnerable because GPS signals are inherently weak and easily disrupted by onboard electronics. To mitigate interference, conductive tape provides a lightweight, flexible solution for wrapping around GPS modules and cables, while conductive O-rings deliver EMI and environmental sealing for antenna mounts. These solutions improve GPS lock and accuracy without adding significant weight.

Communication Systems (Telemetry, RF Links)

Communication systems, including telemetry and RF links, face the challenge of both emitting and receiving interference, which can compromise data transmission. Connector gaskets are used to shield RF connectors and prevent leakage, while conductive elastomers isolate RF modules within enclosures. This combination reduces crosstalk and ensures reliable long-range communication.

Power Distribution System (PDB, ESCs, Batteries)

The power distribution system, which includes ESCs, batteries, and wiring, generates strong EMI due to high-current switching. Conductive tape is an effective solution for wrapping ESCs and power cables to suppress emissions, while conductive elastomers provide shielding for power modules inside housings. These measures reduce radiated and conducted emissions, improving compliance with EMI standards.

Payload Systems (Cameras, Sensors, LIDAR)

This subsystem includes the accessories or payload relevant to the applications for which commercial drones are used, such as photogrammetry, cinematography, field mapping, digital elevation models, monitoring and surveillance. For payload systems such as cameras, sensors, and LIDAR, EMI can corrupt data integrity and degrade performance. To prevent this, conductive O-rings and elastomers are used for enclosure sealing, while conductive tape offers quick shielding for cables and connectors. These solutions preserve image quality and sensor accuracy while protecting against environmental contaminants.

Motors & Actuators

Motors and actuators are major EMI sources that can affect nearby electronics. Conductive tape is applied to motor leads and housings to suppress emissions, and connector gaskets shield motor connectors. These lightweight solutions minimize EMI coupling into control circuits without impacting mechanical performance.

Overcoming Galvanic Compatibility Challenges in EMI Shielding

This whitepaper addresses the critical issue of galvanic compatibility in TE's EMI shielding, highlighting the corrosion risks that arise when incompatible metals are paired. It offers a detailed analysis of the electrochemical interactions that cause material degradation and impact shielding performance. The paper presents practical solutions, including optimal material selection, protective coatings, and design techniques, to overcome these challenges and enhance the durability and efficiency of EMI shielding systems.

Download Now