Using filtering to operate any relay coil

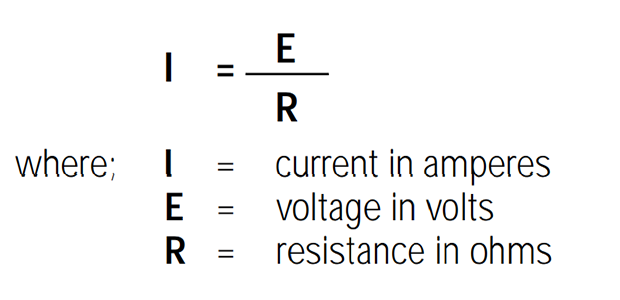

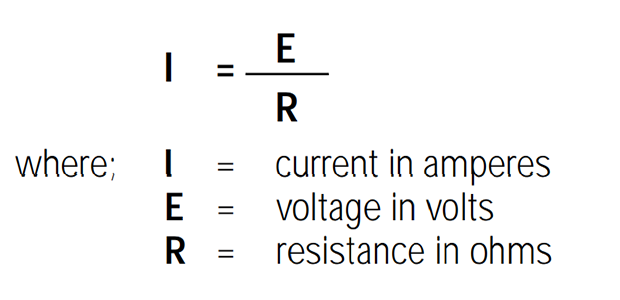

A relay coil is copper wire wound many times on and around a bobbin in which an iron core is situated. When a voltage of sufficient magnitude is impressed across the coil, the coil and core develop magnetism which attracts the armature. The armature, in turn, controls contact movement. Depending on the total length of the wire and its unit cross-sectional area, the coil exhibits a certain amount of resistance to the flow of electric current. According to Ohm’s Law, for a given amount of resistance, current is directly proportional to voltage. That is:

Thus, a 12V DC coil that has 120 ohms of resistance pulls 0.1 amp of current. Some relay coils accept DC voltage, while others accept AC voltage. DC (direct current) voltage has a constant, unchanging value. At any given instant of time, a 12V DC power source measures exactly 12 volts (give or take a few tenths of a volt, normally). (See Fig. 1A)

Thus, a 12V DC coil that has 120 ohms of resistance pulls 0.1 amp of current.

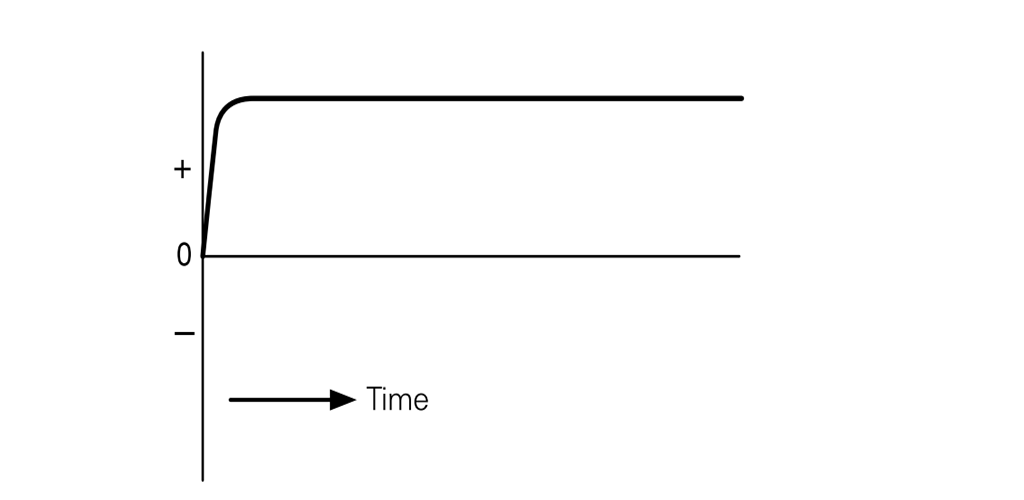

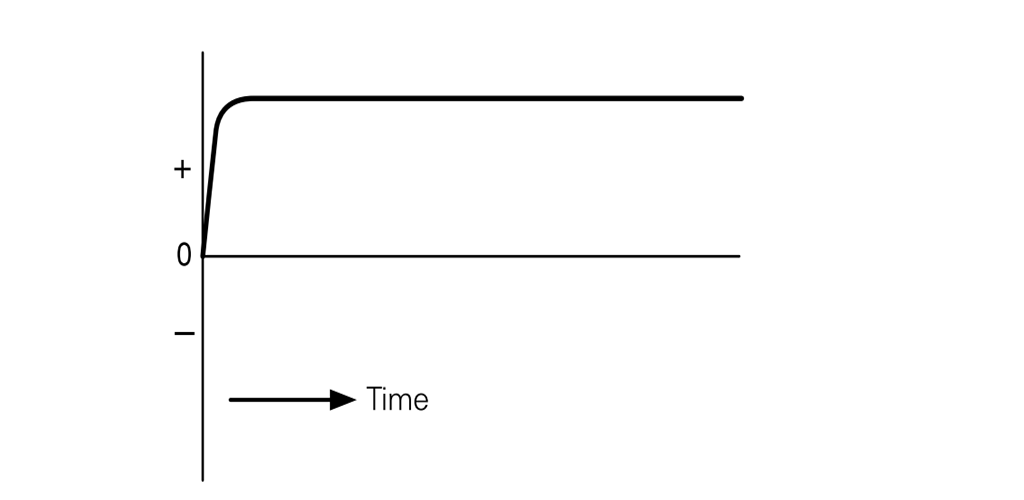

Some relay coils accept DC voltage, while others accept AC voltage. DC (direct current) voltage has a constant, unchanging value. At any given instant of time, a 12V DC power source measures exactly 12 volts (give or take a few tenths of a volt, normally). (See Fig. 1A)

Figure 1a. DC voltage waveform.

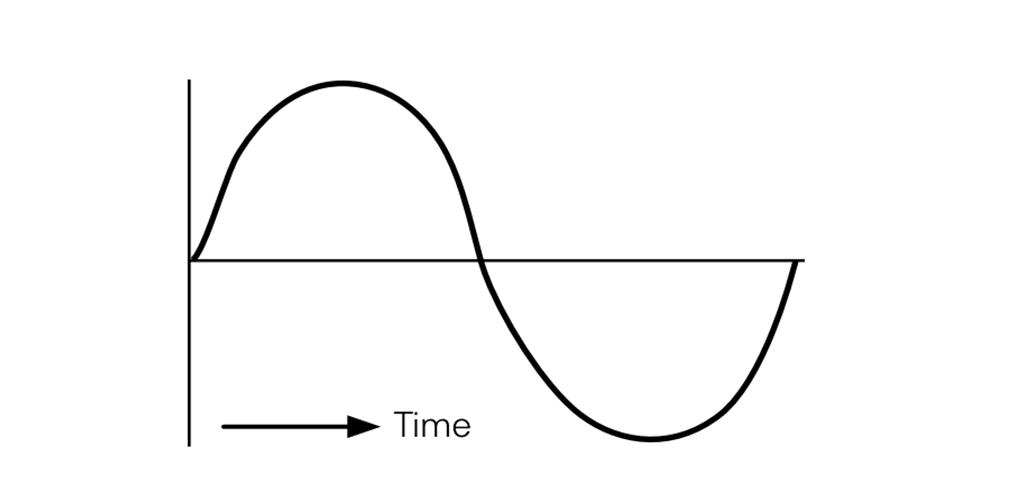

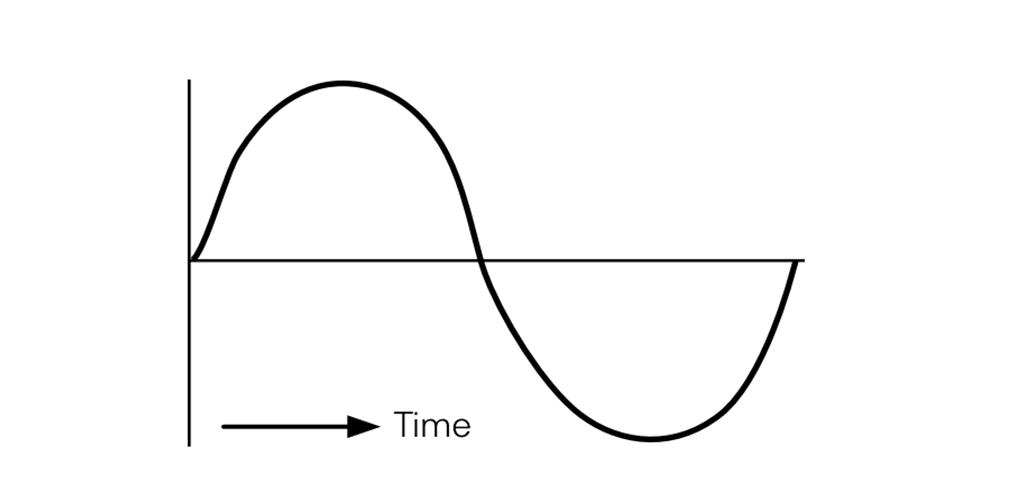

AC (alternating current) voltage, conversely, is constantly changing in value. As pointed out in lesson 2 of the Siemens Electromechanical Components self-study series, “Understanding Relays,” at any given instant of time, the voltage on a 120V AC line, for example, is undergoing a change. (See Fig. 1B) That is, voltage begins at zero, increases to a AC (alternating current) voltage, conversely, is constantly changing in value. As pointed out in lesson 2 of the Siemens Electromechanical Components self-study series, “Understanding Relays,” at any given instant of time, the voltage on a 120V AC line, for example, is undergoing a change. (See Fig. 1B)

Figure 1b. AC voltage waveform.

That is, voltage begins at zero, increases to a peak value, decreases to zero, crosses zero and increases to peak in the opposite direction, then decreases to zero again. This process continuously repeats.

Assume that this 120V AC is to be transformed to 12 volts and impressed across the 12V DC coil. A measure of coil current would show that considerably less than the current calculated by Ohm’s Law would flow in the coil (and its associated circuit). This reduction in coil current is the result of the impedance the coil presents to the alternating current. (Impedance is a function of inductance, and is present only when alternating current flows.)

In order to operate its armature, a certain amount of power must be developed in the relay coil. Since power is the product of current-squared times resistance (P = I2 R), the amount of power developed in the coil would be considerably less than that required for proper relay operation. To develop the required power, coil voltage would have to be increased to that value where sufficient current flows.

In theory, then, AC can be used to operate a DC relay. In reality, however, doing so is impractical. Since alternating current decreases to zero every half-cycle (120 times per second for 60 cycle voltage), the relay armature tends to release every half-cycle. This continual movement of the armature not only causes an audible “buzz,” but will cause the contacts to open and close as the armature moves.

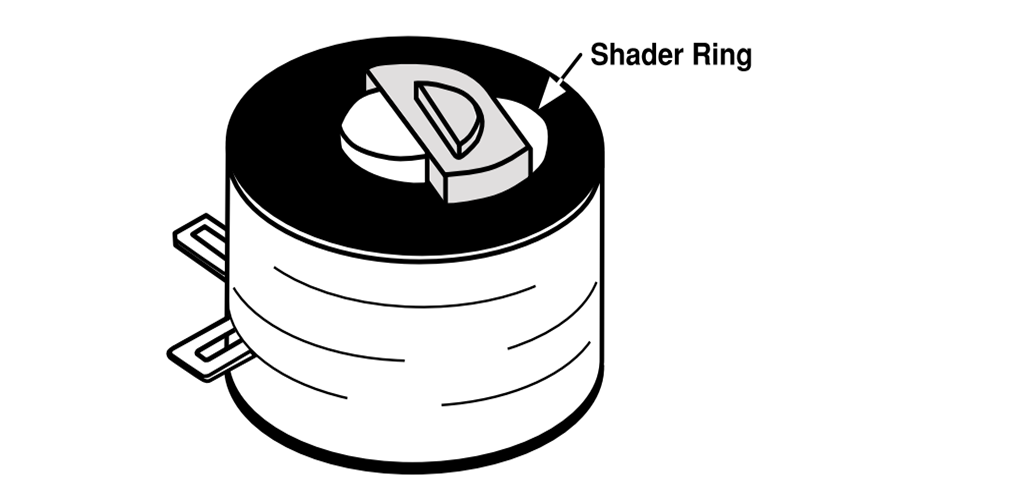

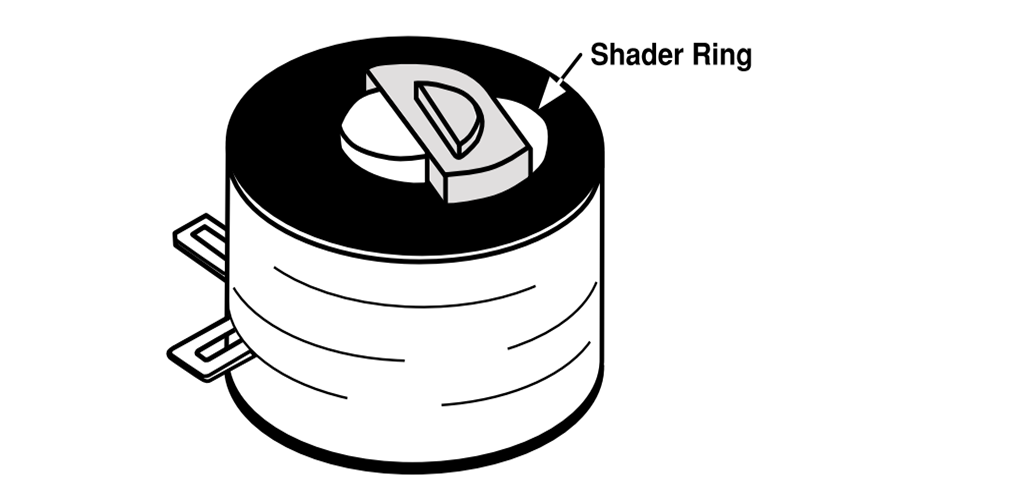

In order to operate a relay from AC, relay manufacturers use a device known as a shader ring (or shader coil) on top of the core. (See Fig. 2). Because of the shader ring, the magnetism developed in part of the core lags somewhat the magnetism of the remainder of the core. That is, there is a slight phase displacement between the magnetism of part of the core and the remainder of the core. Thus, as unshaded-core magnetic energy decreases to zero every half-cycle, the magnetic energy decreases to zero every half-cycle, the magnetic energy still present in the shaded portion of the core holds the armature sealed. By the time the energy in the shaded portion decreases to zero, coil and unshadedcore magnetic energy have begun to increase once again as current increases in value.

Figure 2. AC coils use a shader ring to prevent the relay armature from releasing as magnetic energy decreases to zero every AC half-cycle.

“Shading” the R10 Series (AC Coil) Relay

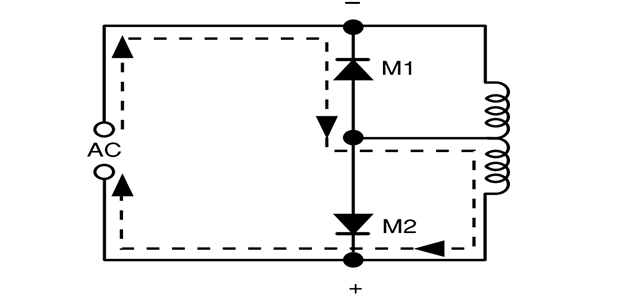

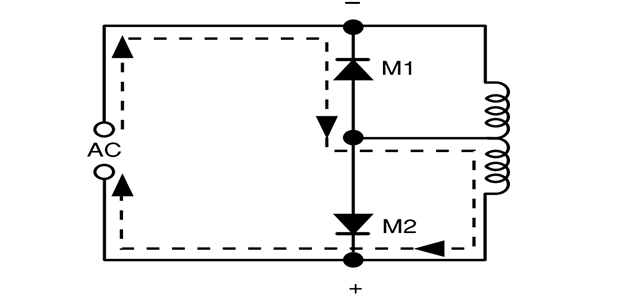

The R10 (and competitive) relays use a unique method of shading the coil. As shown in Fig. 3, when AC voltage on the top side of the coil goes negative, diode M1 conducts current through the bottom half of the coil.

Since M1 is in parallel with the top half of the coil, no current is present in the top half of the coil. However, as a result of magnetizing one half of the coil and the resultant core magnetism, magnetic energy is generated in the top half of the coil. This magnetic energy lags somewhat that of the conducting half of the coil and, as just described, serves to hold the armature seated when current decreases to zero.

When AC voltage reverses, diode M2 conducts and M1 turns off. Coil current is now present in the top half of the coil and generates magnetism of the same polarity as that remaining from the previous half-cycle. Thus, the armature has no chance to release. As before, the nonconducting part of the coil serves as a shader to hold the armature seated. A diode may be used in series with a relay coil, and serves to rectify the AC voltage. However, a diode should never be placed in parallel with the coil in an AC circuit. Doing so would result in the diode conducting, not the relay, as voltage swings negative on the diode. (Besides, the first time the diode conducts, it will be destroyed because there is nothing in series with it to limit current.)

DC on an AC Relay

Just as it is impractical to operate a DC relay from AC, it is likewise impractical to operate an AC relay from DC. However, in an emergency, an AC relay may be operated from DC—provided certain precautions are taken. The first precaution is to provide some type of a residual break between relay core and armature to prevent the armature from “sticking” as a result of any appreciable residual magnetism remaining in the core after coil power is removed. The second precaution that should be taken is to make sure the amount of DC voltage used is less than the AC voltage rating of the coil.

Regarding the residual break, AC relays are so constructed that when the armature is in its seated position, it physically (magnetically) touches the core. (On DC relays, a small copper pin in the armature effectively prevents the armature from coming in magnetic contact with the core.) As long as the AC relay is operated from AC voltage, there is no problem with residual magnetism holding the armature seated after release of coil power. But when an AC relay is operated from DC voltage, there is a danger that residual magnetism may hold the armature seated. At the very least, the presence of residual magnetism in the core causes a reduction in the dropout voltage of the relay.

To negate the effects of residual magnetism, a small piece of mylar tape may be stuck to the top of the AC relay core. This tape is extremely durable, and should last for perhaps hundreds (if not thousands) of operations. The tape should be .002” to .004” thickness.

Regarding the required reduction in coil voltage, consider the KR series relay coil. The 12V AC coil has a DC resistance of 24 ohms. According to Ohm’s Law, 12 volts divided by 24 ohmsequals 0.5 ampere. However, as pointed out on the KR data sheet, the coil actually pulls just .168 ampere! (This is the result of coil impedance.) This .168 ampere causes the coil to develop sufficient power to perform its intended work. However, the 0.5 ampere would cause 6 watts of power to be developed. This is well in excess of the maximum allowed. As a result, the coil would overheat and wire insulation would burn off. Then the coil turns would short together. The coil would pull even more current, and finally burn out completely.

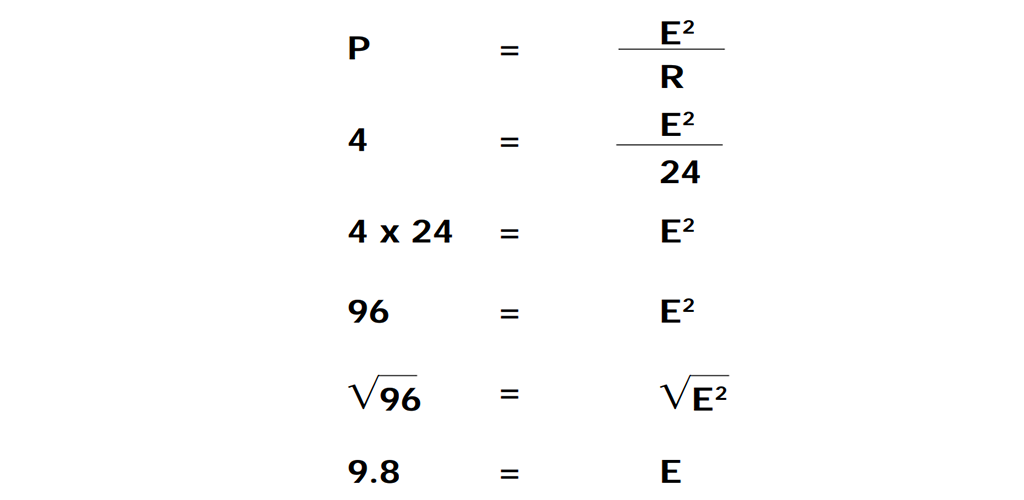

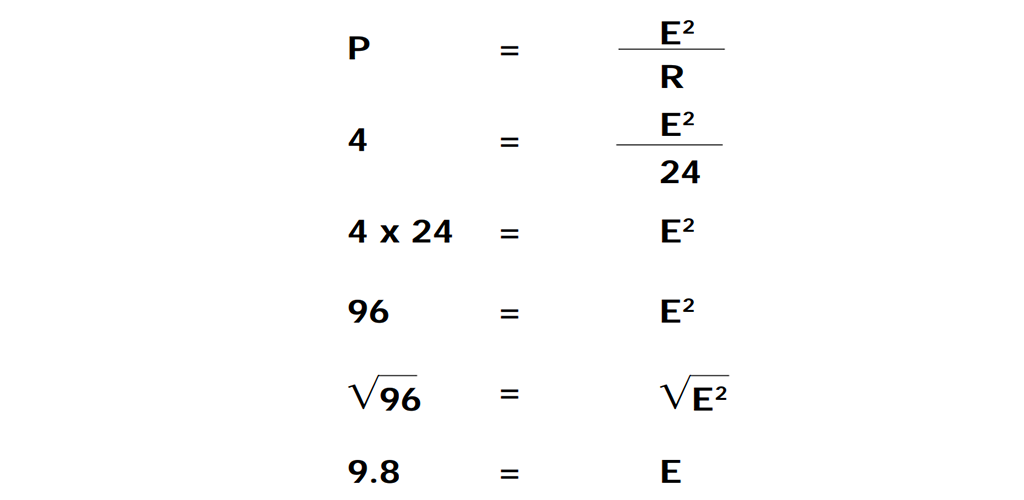

To use an AC coil on DC requires lowering the amount of DC voltage to that value where coil power is within maximum limits. Again consider the KR. The open-style unit has a maximum power rating of 4 watts. To determine the amount of DC voltage to use with a 12V AC coil having a DC resistance of 24 ohms:

Thus, DC voltage cannot exceed 9.8 volts. Since the data sheet lists the pick up value when using DC voltage as 75% of rated value, the DC voltage in this example should not be lower than 7.35 volts.

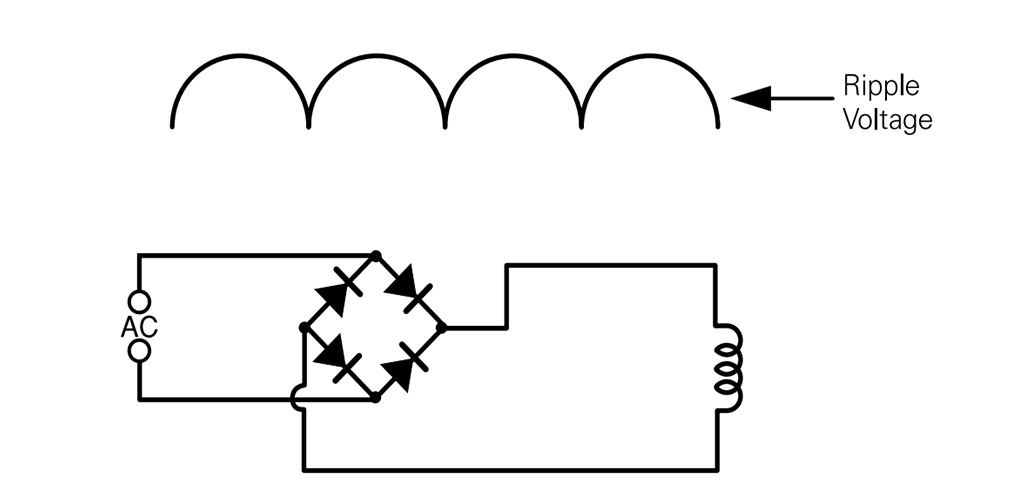

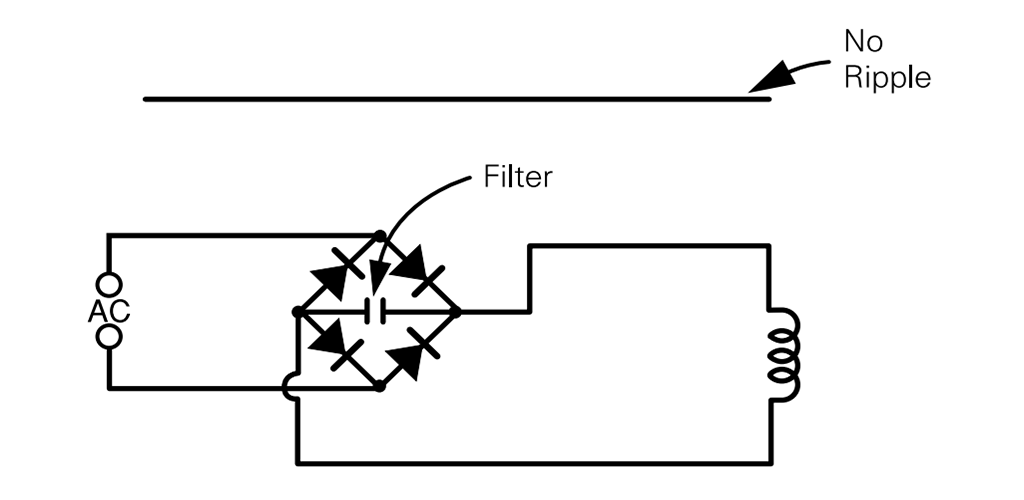

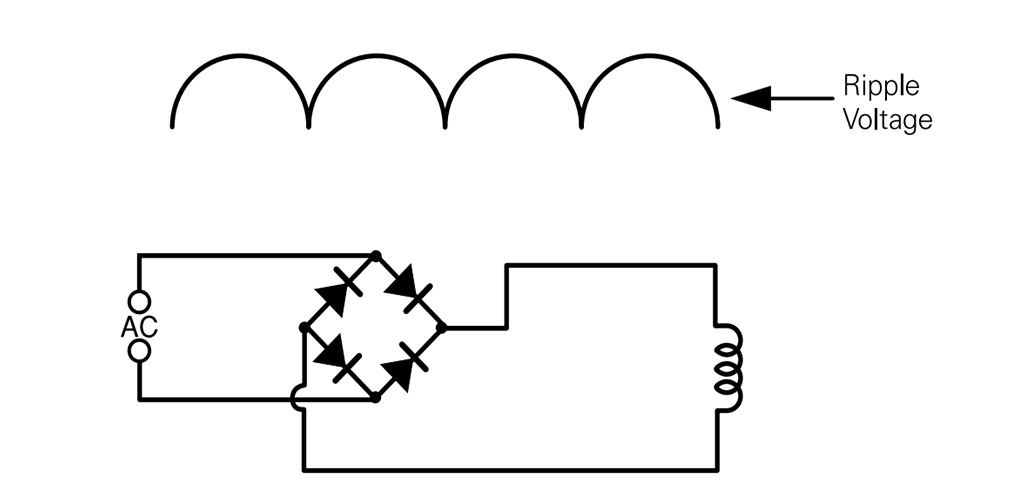

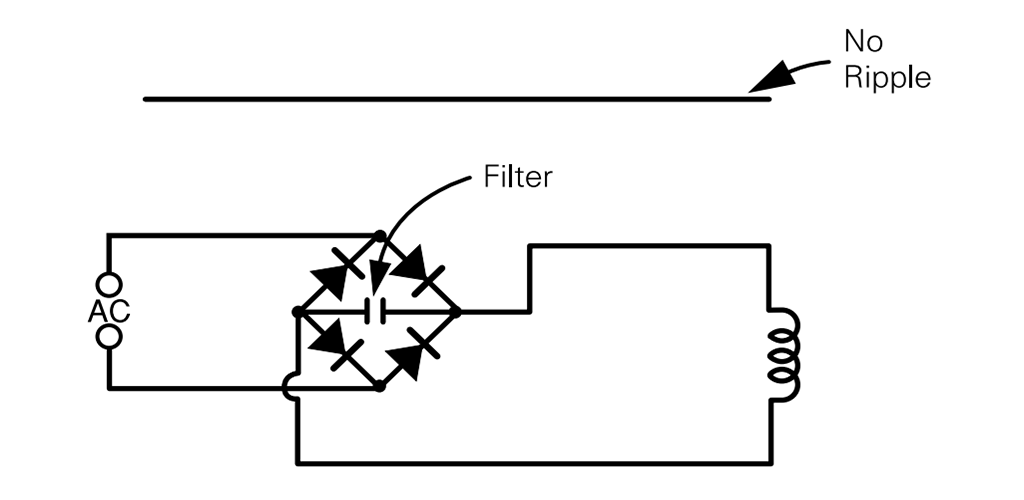

When using rectified AC to operate any relay coil, it is best to use filtering. As shown in fig. 4A, AC that is rectified but unfiltered has voltage peaks and valleys—that is, maximum and minimum values. If the minimum values should be 75% or less of rated voltage, the armature might experience movements. As shown in Fig. 4B, filtering eliminates ripple. Thus, rectified and properly filtered AC will have no appreciable ripple.

Figure 4a. Rectified, unfiltered AC voltage has ripple present.

Figure 4b. Rectified, filtered AC has little or no ripple present.

Using filtering to operate any relay coil

A relay coil is copper wire wound many times on and around a bobbin in which an iron core is situated. When a voltage of sufficient magnitude is impressed across the coil, the coil and core develop magnetism which attracts the armature. The armature, in turn, controls contact movement. Depending on the total length of the wire and its unit cross-sectional area, the coil exhibits a certain amount of resistance to the flow of electric current. According to Ohm’s Law, for a given amount of resistance, current is directly proportional to voltage. That is:

Thus, a 12V DC coil that has 120 ohms of resistance pulls 0.1 amp of current. Some relay coils accept DC voltage, while others accept AC voltage. DC (direct current) voltage has a constant, unchanging value. At any given instant of time, a 12V DC power source measures exactly 12 volts (give or take a few tenths of a volt, normally). (See Fig. 1A)

Thus, a 12V DC coil that has 120 ohms of resistance pulls 0.1 amp of current.

Some relay coils accept DC voltage, while others accept AC voltage. DC (direct current) voltage has a constant, unchanging value. At any given instant of time, a 12V DC power source measures exactly 12 volts (give or take a few tenths of a volt, normally). (See Fig. 1A)

Figure 1a. DC voltage waveform.

AC (alternating current) voltage, conversely, is constantly changing in value. As pointed out in lesson 2 of the Siemens Electromechanical Components self-study series, “Understanding Relays,” at any given instant of time, the voltage on a 120V AC line, for example, is undergoing a change. (See Fig. 1B) That is, voltage begins at zero, increases to a AC (alternating current) voltage, conversely, is constantly changing in value. As pointed out in lesson 2 of the Siemens Electromechanical Components self-study series, “Understanding Relays,” at any given instant of time, the voltage on a 120V AC line, for example, is undergoing a change. (See Fig. 1B)

Figure 1b. AC voltage waveform.

That is, voltage begins at zero, increases to a peak value, decreases to zero, crosses zero and increases to peak in the opposite direction, then decreases to zero again. This process continuously repeats.

Assume that this 120V AC is to be transformed to 12 volts and impressed across the 12V DC coil. A measure of coil current would show that considerably less than the current calculated by Ohm’s Law would flow in the coil (and its associated circuit). This reduction in coil current is the result of the impedance the coil presents to the alternating current. (Impedance is a function of inductance, and is present only when alternating current flows.)

In order to operate its armature, a certain amount of power must be developed in the relay coil. Since power is the product of current-squared times resistance (P = I2 R), the amount of power developed in the coil would be considerably less than that required for proper relay operation. To develop the required power, coil voltage would have to be increased to that value where sufficient current flows.

In theory, then, AC can be used to operate a DC relay. In reality, however, doing so is impractical. Since alternating current decreases to zero every half-cycle (120 times per second for 60 cycle voltage), the relay armature tends to release every half-cycle. This continual movement of the armature not only causes an audible “buzz,” but will cause the contacts to open and close as the armature moves.

In order to operate a relay from AC, relay manufacturers use a device known as a shader ring (or shader coil) on top of the core. (See Fig. 2). Because of the shader ring, the magnetism developed in part of the core lags somewhat the magnetism of the remainder of the core. That is, there is a slight phase displacement between the magnetism of part of the core and the remainder of the core. Thus, as unshaded-core magnetic energy decreases to zero every half-cycle, the magnetic energy decreases to zero every half-cycle, the magnetic energy still present in the shaded portion of the core holds the armature sealed. By the time the energy in the shaded portion decreases to zero, coil and unshadedcore magnetic energy have begun to increase once again as current increases in value.

Figure 2. AC coils use a shader ring to prevent the relay armature from releasing as magnetic energy decreases to zero every AC half-cycle.

“Shading” the R10 Series (AC Coil) Relay

The R10 (and competitive) relays use a unique method of shading the coil. As shown in Fig. 3, when AC voltage on the top side of the coil goes negative, diode M1 conducts current through the bottom half of the coil.

Since M1 is in parallel with the top half of the coil, no current is present in the top half of the coil. However, as a result of magnetizing one half of the coil and the resultant core magnetism, magnetic energy is generated in the top half of the coil. This magnetic energy lags somewhat that of the conducting half of the coil and, as just described, serves to hold the armature seated when current decreases to zero.

When AC voltage reverses, diode M2 conducts and M1 turns off. Coil current is now present in the top half of the coil and generates magnetism of the same polarity as that remaining from the previous half-cycle. Thus, the armature has no chance to release. As before, the nonconducting part of the coil serves as a shader to hold the armature seated. A diode may be used in series with a relay coil, and serves to rectify the AC voltage. However, a diode should never be placed in parallel with the coil in an AC circuit. Doing so would result in the diode conducting, not the relay, as voltage swings negative on the diode. (Besides, the first time the diode conducts, it will be destroyed because there is nothing in series with it to limit current.)

DC on an AC Relay

Just as it is impractical to operate a DC relay from AC, it is likewise impractical to operate an AC relay from DC. However, in an emergency, an AC relay may be operated from DC—provided certain precautions are taken. The first precaution is to provide some type of a residual break between relay core and armature to prevent the armature from “sticking” as a result of any appreciable residual magnetism remaining in the core after coil power is removed. The second precaution that should be taken is to make sure the amount of DC voltage used is less than the AC voltage rating of the coil.

Regarding the residual break, AC relays are so constructed that when the armature is in its seated position, it physically (magnetically) touches the core. (On DC relays, a small copper pin in the armature effectively prevents the armature from coming in magnetic contact with the core.) As long as the AC relay is operated from AC voltage, there is no problem with residual magnetism holding the armature seated after release of coil power. But when an AC relay is operated from DC voltage, there is a danger that residual magnetism may hold the armature seated. At the very least, the presence of residual magnetism in the core causes a reduction in the dropout voltage of the relay.

To negate the effects of residual magnetism, a small piece of mylar tape may be stuck to the top of the AC relay core. This tape is extremely durable, and should last for perhaps hundreds (if not thousands) of operations. The tape should be .002” to .004” thickness.

Regarding the required reduction in coil voltage, consider the KR series relay coil. The 12V AC coil has a DC resistance of 24 ohms. According to Ohm’s Law, 12 volts divided by 24 ohmsequals 0.5 ampere. However, as pointed out on the KR data sheet, the coil actually pulls just .168 ampere! (This is the result of coil impedance.) This .168 ampere causes the coil to develop sufficient power to perform its intended work. However, the 0.5 ampere would cause 6 watts of power to be developed. This is well in excess of the maximum allowed. As a result, the coil would overheat and wire insulation would burn off. Then the coil turns would short together. The coil would pull even more current, and finally burn out completely.

To use an AC coil on DC requires lowering the amount of DC voltage to that value where coil power is within maximum limits. Again consider the KR. The open-style unit has a maximum power rating of 4 watts. To determine the amount of DC voltage to use with a 12V AC coil having a DC resistance of 24 ohms:

Thus, DC voltage cannot exceed 9.8 volts. Since the data sheet lists the pick up value when using DC voltage as 75% of rated value, the DC voltage in this example should not be lower than 7.35 volts.

When using rectified AC to operate any relay coil, it is best to use filtering. As shown in fig. 4A, AC that is rectified but unfiltered has voltage peaks and valleys—that is, maximum and minimum values. If the minimum values should be 75% or less of rated voltage, the armature might experience movements. As shown in Fig. 4B, filtering eliminates ripple. Thus, rectified and properly filtered AC will have no appreciable ripple.

Figure 4a. Rectified, unfiltered AC voltage has ripple present.

Figure 4b. Rectified, filtered AC has little or no ripple present.