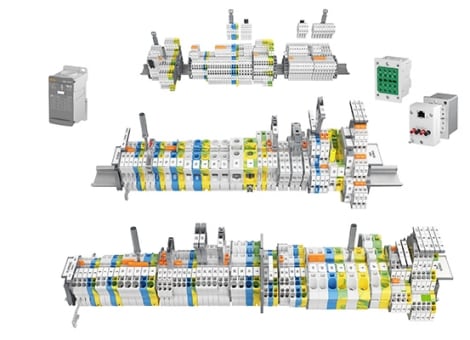

Barrier Strips for Power Applications

A barrier strip is designed for power applications and incorporates a flip-open clear safety cover. Barrier strips contain stray or frayed wire ends and prevent electrical shorts between positions on the same block, as well as adjacent components.

Features

- Available in Centerline spacing from 0.250-0.4375 inch

- Positions sizes 2 to 30

- Accepts wire range from 10-30 AWG dependant on style

- Clamp screws are best suited for bare wire applications

- Binding head style and wire clamp screws are available; binding head screws are typically used with hardware such as QC tabs and jumpers

- Full line of accessories includes jumpers, quick connect tabs, and some covers

Common contact styles offered in both dual and tri-barriers:

- PCB pin

- Extended PCB pin

- Insulated extended. PCB pin

- Wire wrap

- Insulated wire wrap

- Solder turret

- Insulated solder turret

- Quick connect

- Insulated quick connect

- Non feed-thru

Barrier Strips is an interconnect which consists of a metal strip, and connectors or screws, that allows for termination and connection of wires. Barrier strip style terminal blocks are available in three main categories: Dual Barrier, Tri-Barrier, and Double Row. Each category of barrier strip is offered in several industry standard centerline spacings, allowing you to choose from high density to high current applications. Dual Barriers and Tri-Barriers are very similar in that they are both offered with hardware which allows them to be used in either PCB or panel mount applications.

Applications

- Machine controls

- Power Supplies

- Test and measurement

- Automation equipment

- Security/alarm devices

- HVAC controls

- Garage door openers

- Furnaces, water heaters, boilers