Custom connector design solutions for challenging subsea applications

From standard needs to sophisticated custom designs, TE Connectivity Marine, Oil and Gas is a single source supplier for specialty underwater connectors. Our products and process capabilities for metal, polymer and composite connectors, coupled with our innovative technologies and expertise in subsea applications makes us a premier supply partner. Our global manufacturing footprint enables a seamless manufacturing solution for your specialty cable assemblies, from the surface to the bottom of the sea floor.

Specialty Products

TE Connectivity (TE) has the engineering and production capability to help design, manufacture, and deliver the solution to your connector challenges. These include many solutions including hazardous zone rated connections (zone 1, class 1, EX rated), fluroelastomer molded Connectors, seismic array inserts, small profile military arrays, cable protection, subsea jumper assemblies and many more.

Specialty Products

- Pressure: up to 20,000 psig (approx. 46,133ft/14,064m)

- Voltage: up to 5,000 VAC

- Materials: Titanium, hastelloy, inconel, monel, nitronic 50 and several engineering plastics

- Pressure balanced oil-filled system to standard cable system transitions

- Several connectors designed to interface directly with specific underwater lamp bulbs

- Several high density towed array inserts

- Many custom inserts for the downhole Industry

FLUROELASTOMER SERIES

This 8 way connector pair was designed for a wire line tool which is fitted within an arm leading to a sensing pad. This meant that when the tool was retrieved the sensing pad could be changed out quickly and easily without tooling or special training. As the connector would directly see wellbore fluids at high pressures and temperatures the connector is moulded in fluoroelastomer. The cable has an outer jacket of ETFE so a booting technique has been used to seal to the cable jacket. This gives the benefit that the free half connectors are field installable, but soldering is required.

The connection philosophy is based around our standard wet-con connector range. The pin contact has a sealing diameter and when this is connected into the socket bore two integrally moulded o-rings impinge onto this diameter.This means that there are two o-ring seals between contact and earth and four o-ring seals between different contacts. As there are no pressure differentials in the design the connector pair are pressure tolerant.

Download the Brochure

Fluroelastomer Series

FEATURES

- High temperature rating

- High pressure rating

- Excellent electrical properties

- Eight electrical contacts

- Harsh environment compatible

- Positive external grip for disconnection

- Small size and weight

- Field installable free halves

- Push-on pull-off design (sealing retention retains connectors)

- Keying achieved by contact face pattern

- Wet mateable

Subsea Umbilical Termination Assembly (SUTA)

The Optical Subsea Umbilical Termination Assembly or SUTA is a termination and distribution unit for optical cables.It contains an integral pressure balanced compensation system, fiber management system, mechanical armor termination and fiber k-tube feed-through penetrations.

Download the Brochure

Features

SUTA

FEATURES

- Integral fiber management system

- High pressure fiber optic feed-through penetrations boot seals

- Depth rating: Full ocean depth

- Field installable (no compounds)

- Oil filled and pressure compensated dual o-ring seals

- Slide over cover for easy access and assembly

- Secure splice tray for maximum fiber stability

- Small - 5" (127mm) Diameter 15" (381mm) Length

- Modular cable termination design to facilitate different cables

- Options for multiple cable entry

- Options for multiple connections

75 Ohm Coax Connector

Developed for the camera industry where a new HD camera required impedance matched coax and signal lines. This new connector is based around Seacon MINL-CCPL shell size with the FCRL having a combination of the MINL front end interface, but with a Seacon 5515 FCR mounting interface. The CCPL insert is manufactured from moulded PEEK (Polyetheretherketone) with a 316L Stainless Steel connector shell. The bulkhead have a glass to metal sealed insert and has been open-face pressure tested to 8,400 psig. This new 75 ohm coax connector is also available with the bulkhead having the standard MINL-BCRL mounting interface.

Download the Brochure

75 Ohm Coax Connector

FEATURES

- Based around existing design

- Available in alternative materials

- Suitable for a variety of applications

Universal Joint Bend Restrictor Connector

The bend restrictor utilizes a universal joint design that allows cable bending through restricted space areas whilst still providing an adequate level of strain relief and bend restriction of the cable system. In addition the bend restrictor terminates the required cable with a dry mateable connector suitable for deepwater operation. Also suitable for small bore modular arrays.

Download the Brochure

Universal Joint Bend Restrictor Connector

- Mated length: 1.2m (48 inches)

- Overall diameter: 6.4cm (2.5 inches)

- Operating tensile Load: 267 kN (60,000 lbf)

- Dynamic cyclic bend load: 50 kN (11,000 lbf)

- Depth rating: 1,500m (5,000ft) suitable for MSS,Mini-Con and Micro Mini-Con series of dry mateable connectors

- Modular cable terminations

Jumper Assembly

Subsea jumper assemblies and distribution harnesses are provided by TE Connectivity (TE)’s SEACON for use with subsea connectors. Many subsea electrical and optical cable and connection systems utilize Pressure Balanced Oil Filled (PBOF) cabling solutions. These hoses and junction boxes utilize an elastomeric tube as a conduit for electric wires and fiber optic lines. The elastomeric conduit is filled with a compensating fluid, allowing the sea pressure to equalize the pressure differential within the interior oil volume.

Download the Brochure

Jumper Assembly

FEATURES

FIELD RELIABILITY

• Temperature and pressure Compensated • Tested to 450 bar • Ozone protection

EASE OF USE

• Designed for ROV handling • Good ROV maneuverability during connector mating • Deployment techniques similar to jacketed cable

PULL TESTED

• Each assembly tension tested at 3750 N • High visibility, orange in color • Two layer design with tension and pressure armor in between

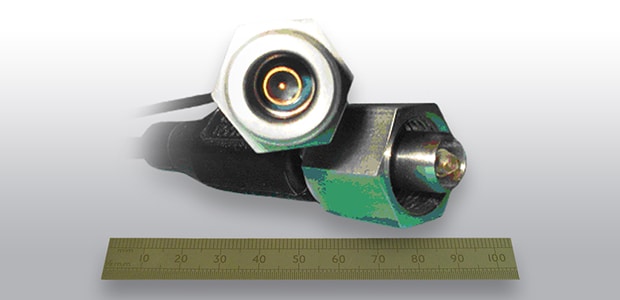

50 Ohm Coax Connector

The 50 ohm coax connector is a small dry mateable coax connector with impedance of 50 ohms. The connector is mated together via a robust stainless steel locking sleeve and sealed by a piston & face o-ring seal. The bulkhead connector has a gold plated pin and sleeve glass sealed into the stainless steel body. The coax cable on the free half connector is molded to the connector shell and the cable in Polyurethane.

Download the Brochure

50 Ohm Coax Connector

FEATURES

- High pressure rating

- Excellent electrical properties

- Dual sealing on connection

- Small size & weight

- No keying

- Rugged design & construction

- Dry mateable

- Glass sealed bulkhead

- Excellent environmental compatibility