-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

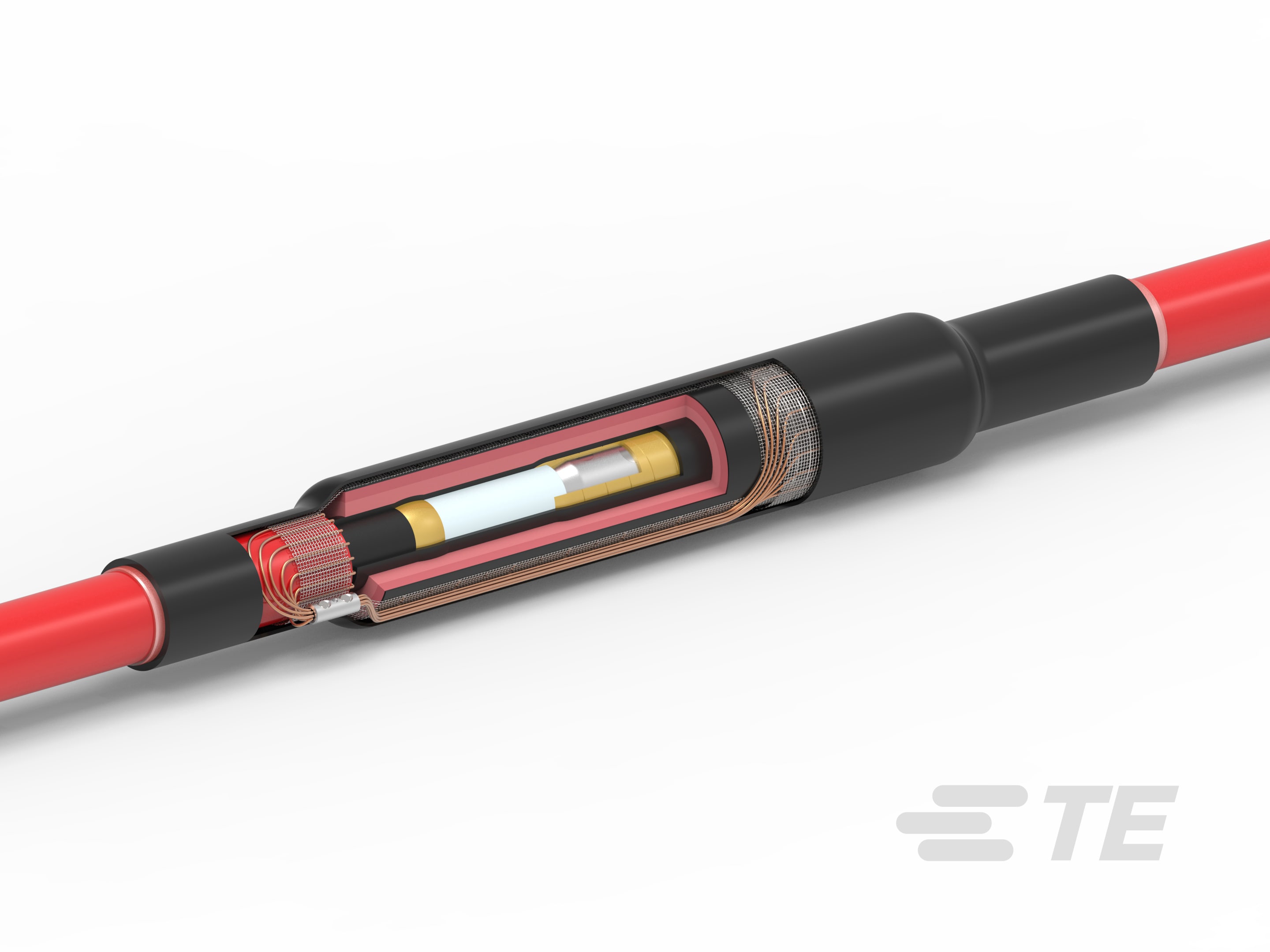

Heat Shrink Cable Joints 12-42 kV

- RAYCHEM

- RAYCHEM MXSU

Product Features

-

Installation Technology : Heat Shrink

-

Product Availability : Americas, Asia, Australia, New Zealand & Pacific Islands, China, Europe, Middle East & Africa

-

Installation Instruction : Dutch, English, Finnish, Flemish, French, German, Hungarian, Italian, Spanish, Swedish

-

Joints & Splice Product Type : Inline Joint, Medium Voltage Size Transition Joint, Repair Joint

-

Voltage Class (kV): ≤ 12, ≤ 24, ≤ 36, ≤ 17.5

Available from

Our Raychem MXSU-INL-1C Heat Shrink Cable Joint is based on a joint design using mechanical shear bolt connectors for conductor and wire shields, which are also supplied with the kit. The kits widely range taking and cover most conductor constructions including their tolerances. Thanks to the shear bolt technology the joints are easy to install - no crimping tools needed when connecting the cables, no tool maintenance required. They can be installed with a standard socket spanner. The heads of the bolts will shear off when the needed torque is applied, ensuring an optimal electrical contact. The Heat Shrink Cable Joints are short and have a space-saving design, an essential characteristic when space is limited. Reliability and performance are essential when it comes to customer demands and the heat shrink joints exceed international performance standards including CENELEC HD 629 or IEC 60502-4 for joints.

Key Features

- All-inclusive kit

- Based on elastomeric triple layers joint sleeve

- Short and slim design

- Requires no crimping tool

- Includes mechanical connectors

- Meets CENELEC HD 629

Heat Shrink Cable Joints

Improving Grid Connectivity

Watch our video to learn more about how to install TE's Raychem Heat Shrink Joint MXSU.

Power Cable Terminations

Question: Heat Shrink Cable Joints are designed to which specifications?

Answer: Our Heat Shrink Cable Joints for 12 to 42 kV are designed and type tested to the Cenelec HD-629.1 S2 specification.

Question: Would a Heat Shrink Cable Joint work on all cables available for the referred cross-section?

Answer: Cable constructions and dimensions can be different around the world for the same cross-section. For safe and reliable applications the admissible cable dimensions provided in the product data-sheet should be followed.

Question: What are the main advantages of the Heat Shrink Cable Joints product family?

Answer: This Heat Shrink Cable Joints family is one of several other joint families using mechanical shear bolt connectors to simplify installations, covering nearly all cable sizes available. There are more than 20 years of field experience applied to this joint sleeve design, proving advantageous especially in transition joints and where oil pressure retention is key.

Question: Is there any need for special installation tools or extra material?

Answer: No, there are no special installation tools or materials required. The Heat Shrink Cable Joint is an all-inclusive accessory.

Question: Does TE offer any installation training for the Heat Shrink Cable Joints?

Answer: Yes, our Heat Shrink Cable Joints are part of our training program. We can offer different installation training options depending on your needs. This ranges from product demonstrations on-site to full structured training courses at one of our global training facilities. Learn more at: TE.com/trainingcenter

Question: Does TE offer any installation training for the heat shrink joints?

Answer: Yes, our heat shrink joints are part of our training program. We can offer different installation training options dependent on your needs. This ranges from product demonstrations on-site to full structured training courses at one of our global training facilities. Learn more at: TE.com/trainingcenter

Question: Does TE offer any installation training for the heat shrink joints?

Answer: Yes, our heat shrink joints are part of our training program. We can offer different installation training options dependent on your needs. This ranges from product demonstrations on-site to full structured training courses at one of our global training facilities. Learn more at: TE.com/trainingcenter

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Power Component Options Mechanical Connectors Included

-

Joints & Splices Connector Type Mechanical

-

Installation Technology Heat Shrink

-

Joints & Splice Product Type Inline Joint, Medium Voltage Size Transition Joint, Repair Joint

-

Cable Shield Style Wire

Configuration Features

-

Number of Cores 1

Electrical Characteristics

-

Voltage Class (kV) ≤ 12, ≤ 24, ≤ 36, ≤ 17.5

Body Features

-

Insulation Material Polymeric

Dimensions

-

Compatible Conductor Cross-Section Range (mm²) 500, 630, 800, 1000, 120 – 240, 70 – 150, 35 – 95, 95 – 240, 50 – 95, 50 – 150, 240 – 400, 150 – 300

-

Compatible Conductor Range (AWG/kcmil) 1/0 – 4/0

-

Compatible Insulation Diameter Range (mm) 23 – 33.6, 25 – 35.5, 44.8 – 46.9, 31.1 – 39.6, 17.6 – 24, 24 – 30, 33.8 – 37.2, 55.7 – 58.8, 40.1 – 46.6, 25.7 – 32.6, 45.8 – 50.5, 23.5 – 32.6, 19.9 – 27.5, 22 – 31.6, 45 – 47.6, 50.1 – 53.4, 37.2 – 41.6, 49.4 – 53.2, 37.5 – 40, 28.4 – 36.8, 20.2 – 29.5, 39.5 – 42.6, 17.6 – 24.3, 17.6 – 29.4, 26.2 – 34.5

-

Compatible Insulation Diameter Range (in) 1.46 – 1.63, 1.57 – 1.83, .79 – 1.16, .692 – 1.157, 1.33 – 1.46, .905 – 1.322, 1.03 – 1.35, .692 – .956, 1.55 – 1.67, 1.22 – 1.55, .783 – 1.08, 1.76 – 1.84, 1.94 – 2.09, 1.01 – 1.28, .925 – 1.283, .692 – .944, 2.19 – 2.31, 1.97 – 2.1, .984 – 1.39, 1.8 – 1.98, .86 – 1.26, 1.11 – 1.44, 1.77 – 1.87, .94 – 1.18, 1.47 – 1.574

-

Compatible Cable Cross-Section - Main (Max) (mm²) 95, 150, 240, 300, 400, 500, 630, 800, 1000

-

Compatible Cable Cross-Section - Main (Min) (mm²) 35, 50, 70, 95, 120, 150, 240, 500, 630, 800

-

Compatible Cable Diameter - Main (Max) (mm) 65

-

Compatible Conductor Diameter Range (mm) 29 – 32.5, 13.9 – 21.6, 10.3 – 19.2, 8.7 – 15, 6 – 12, 25.5 – 29.2, 12.9 – 21.6, 7.2 – 12, 11 – 19.2, 38.5 – 39.2, 25.5 – 27.6, 32 – 33.8, 7.2 – 15, 17.8 – 24.6

-

Compatible Conductor Diameter Range (in) .433 – .755, 1 – 1.15, 1.25 – 1.33, .23 – .472, .4 – .75, .283 – .472, 1 – 1.08, .7 – .968, .405 – .755, .547 – .85, 1.51 – 1.55, 1.14 – 1.27, .342 – .59, .283 – .59, .507 – .85, .685 – .968

-

Sheath Outside Diameter (mm) 69 – 73, 24 – 38, 62 – 66, 38 – 53, 55 – 68, 28 – 41, 33 – 47, 28 – 44, 48 – 54, 52 – 60, 24 – 60, 25 – 38, 34 – 44, 64 – 67, 33 – 48, 28 – 39, 31 – 45, 35 – 50, 52 – 57, 30 – 43, 58 – 61, 44 – 50, 32 – 43, 26 – 40, 47 – 54, 59 – 64

-

Sheath Outside Diameter (in) 2.44 – 2.6, 1.85 – 2.12, 2.32 – 2.51, 2.51 – 2.63, .944 – 1.49, 1.1 – 1.73, 2.28 – 2.4, 2.04 – 2.24, 1.02 – 1.57, 1.33 – 1.73, 2.16 – 2.67, 1.73 – 1.96, 1.29 – 1.88, 1.37 – 1.96, 1.1 – 1.53, .984 – 1.49, 2.71 – 2.87, 1.25 – 1.69, 1.18 – 1.69, 1.22 – 1.77, 2.04 – 2.36, 1.88 – 2.12, 1.29 – 1.85, 1.49 – 2.08, 1.1 – 1.61

Industry Standards

-

Compatible With Approved Standards Products HD CENELEC 629.1

Product Availability

-

Product Availability Americas, Asia, Australia, New Zealand & Pacific Islands, China, Europe, Middle East & Africa

Packaging Features

-

Packaging Quantity 1

Other

-

Installation Instruction Dutch, English, Finnish, Flemish, French, German, Hungarian, Italian, Spanish, Swedish

Reference Number

-

TE Internal Number CAT-MXSU-INL-1C

Datasheets & Catalog Pages

- MXSU JOINTING SYSTEM pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details