-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

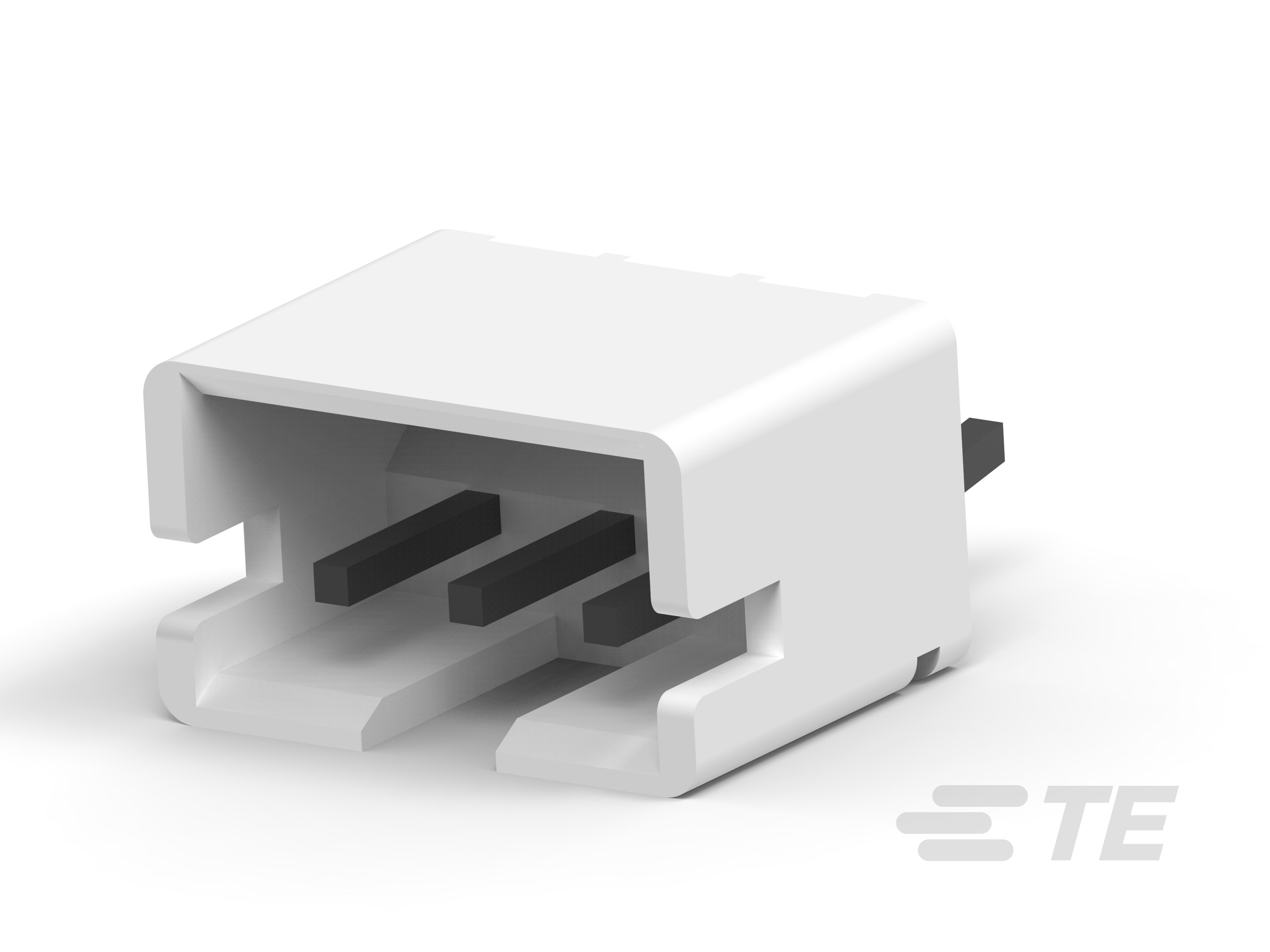

AMP HPI 2.0 mm Headers

Product Features

-

PCB Connector Type : PCB Mount Header

-

PCB Mount Orientation : Right Angle, Vertical

-

Connector System : Wire-to-Board

-

Number of Positions : 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 20, 22, 24, 26, 28, 30, 32

-

Number of Rows : 1, 2

Available from

AMP HPI 2.0MM Headers

- Position count: 2 to 15 for single row and 6 to 32 for dual row

- Available in single or dual row

- Mounting style: SMT or DIP

- Available with vertical or right angle orientation

Select Applications

- Business equipment

- Industrial machines

- Wire-to-board applications

- Plasma display panels

- LCD monitors

- Small electronics equipment

- Anywhere signals or power is routed

Features and Requirements

Q: What gauge wire (AWG) will you be using?

A: TE’s HPI product accepts 22-32 AWG discrete wire. Remember that the higher the AWG measurement number, the smaller the discrete wire. For example, 32 AWG is smaller than 22 AWG will likely have less current carrying capacity.

Q: Are you transferring signal or lower power throughout your device?

A: HPI products are simple interconnect solutions that can be used to transfer signal or lower power in multiple applications across many industries

Q: Does your application have a fan, motor, switch, display, light or any other simple device?

A: HPI product may be a good solution to control these type of ancillary items.

Q: Does your application require a locking feature to strengthen the mating connection between the plug assembly and receptacle?

A: If your application requires a secure mating retention feature, TE’s 2.0mm HPI product line offers an external locking feature to improve the reliability of the interconnect system.

Q: What are the technical requirements of your application?

A: It is imperative that you ask your customer the current and voltage requirements of their application. Current, which is expressed in amps, is usually the driving factor when selecting a small pitch wire-to-board product. Other information that you should consider include operating temperature, PCB real estate, profile height limitations, material restrictions, etc.

Q: What tooling is available to apply TE’s wire-to-board products?

A: TE’s tooling divisions offer a wide range of hand tools, semi-automatic, and automatic tools. Please visit Application Tooling to determine the application tooling that meets your needs.

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

PCB Connector Type PCB Mount Header

-

Connector System Wire-to-Board

-

Header Type Fully Shrouded, Partially Shrouded

-

Sealable No

-

Connector & Contact Terminates To Printed Circuit Board

-

Connector Product Type Connector Assembly

Configuration Features

-

Number of Columns 3, 10

-

Number of Loaded Positions 3, 10

-

Connector Contact Load Condition Fully Loaded, Selectively Loaded

-

PCB Mount Orientation Right Angle, Vertical

-

Number of Positions 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 20, 22, 24, 26, 28, 30, 32

-

Number of Rows 1, 2

Electrical Characteristics

-

Operating Voltage (VDC) 100, 250

-

Insulation Resistance (MΩ) 5000

-

Operating Voltage (VAC) 100, 250

Body Features

-

Primary Product Color Black, Blue, Natural, Red, Yellow

Contact Features

-

Contact Mating Area Length (mm) 3.35, 3.5, 3.53

-

Contact Mating Area Length (in) .131, .138, .139

-

PCB Contact Termination Area Plating Material Thickness (µm) 2, 2.032

-

PCB Contact Termination Area Plating Material Thickness (µin) 79.92, 80

-

PCB Contact Termination Area Plating Material Finish Bright, Matte

-

PCB Contact Termination Area Plating Material Thickness (µin) 79.92, 80

-

Mating Square Post Dimension (mm) .5

-

Mating Square Post Dimension (in) .019, .02

-

Contact Base Material Brass, Copper Alloy, Phosphor Bronze

-

Contact Mating Area Plating Material Thickness (µm) 2, 2.032, 2.54

-

Contact Mating Area Plating Material Thickness (µin) 78, 80, 100

-

PCB Contact Termination Area Plating Material Nickel, Tin

-

Contact Underplating Material Nickel

-

Contact Layout Inline

-

Contact Mating Area Plating Material Finish Bright, Matte

-

Contact Shape & Form Square

-

Contact Mating Area Plating Material Gold Flash, Tin (Sn)

-

Contact Type Pin

-

Contact Current Rating (Max) (A) 3

Termination Features

-

Square Termination Post & Tail Dimension .5 mm [ .02 in ]

-

Terminations per Post (Max) 3

-

Termination Post & Tail Length (mm) 1, 2, 2.1, 3, 3.4

-

Termination Post & Tail Length (in) .039, .079, .082, .118, .134

-

Termination Method to PCB Surface Mount, Through Hole - Solder

Mechanical Attachment

-

PCB Mount Retention Type Kinked Legs, Kinked Tines, Retention Solder Tails, Solder Peg

-

Mating Retention With, Without

-

Mating Alignment Type Keyed, Polarization

-

Mating Retention Type Locking

-

PCB Mount Retention With, Without

-

PCB Mount Alignment Without

-

Connector Mounting Type Board Mount

-

Mating Alignment With

Housing Features

-

Housing Material High Temperature Thermoplastic, LCP GF30, Nylon 66, Nylon 66 GF, PA 9T GF, Thermoplastic

-

Centerline (Pitch) (mm) 2

-

Centerline (Pitch) (in) .078, .079

Dimensions

-

PCB Thickness (Recommended) (mm) 1.57, 1 – 1.14, 1 – 1.11, 1 – 1.6, 1 – 1.18, 1 – 1.2, 1 – 1.22, 1 – 1.12, 1 – 1.21

-

PCB Thickness (Recommended) (in) .062, .039 – .048, .039 – .063, .039 – .044, .039 – .045, .039 – .047

-

Connector Length (mm) 6, 7.4, 8, 9.4, 10, 11.4, 12, 13.4, 14, 15.4, 16, 17.4, 18, 19.4, 20, 21.4, 22, 23.4, 24, 25.4, 26, 27.4, 28, 29.4, 30, 31.4, 32, 33.4, 34, 35.4

-

Connector Length (in) .236, .291, .314, .37, .393, .449, .472, .528, .551, .606, .63, .685, .709, .764, .787, .843, .866, .921, .945, 1, 1.024, 1.079, 1.102, 1.158, 1.181, 1.236, 1.26, 1.315, 1.339, 1.394

-

Connector Height (mm) 4.95, 5.5, 5.8, 6.05, 6.07, 6.15

-

Connector Height (in) .194, .195, .217, .228, .238, .239, .242

-

Connector Width (mm) 4.7, 5.2, 5.4, 6.05, 7.6, 7.7

-

Connector Width (in) .185, .205, .213, .238, .299, .303

-

Row-to-Row Spacing 2 mm [ .079 in ]

Usage Conditions

-

Operating Temperature Range -25 – 85 °C [ -13 – 185 °F ]

Operation/Application

-

Circuit Application Signal

Industry Standards

-

Compatible With Approved Standards Products CSA LR7189, UL E28476

-

UL Flammability Rating UL 94V-0

Packaging Features

-

Packaging Quantity 160, 200, 250, 300, 350, 450, 500, 600

-

Packaging Method Bag, Box, Loose Piece, Reel, Tape, Tube

Other

-

Position Locations Omitted 2, 0

Reference Number

-

TE Internal Number CAT-H857-H34220

Datasheets & Catalog Pages

- HPI Connectors QRG pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details