Robotic Assisted Surgery

TE has partnered with the earliest pioneers in robotic assisted surgery. With a wide array of capabilities, TE has the ability to enable the next generation of surgical robots. From highly engineered tubing for surgical instruments, to imaging cables for visualization, and sensors to augment touch and feel, our solutions are found throughout the robotic assisted OR.

TE has been at the forefront of driving progress in surgical robotics, spanning from the initial transformation of keyhole surgery over two decades ago to breakthroughs in robotic microsurgery today. By translating clinical requirements into technological advancements, TE actively engages in the convergence of medical demands and engineering innovations.

TE is committed to facilitating the evolution of compact, intelligent devices that are capable of being miniaturized and imbued with mechatronic enhancements. Our goal is to support medical device OEMs create immersive visualization and highly sensitive sensory systems, aimed at augmenting tactile perception, propelling innovation for the next generation of surgical robots.

Device Solutions

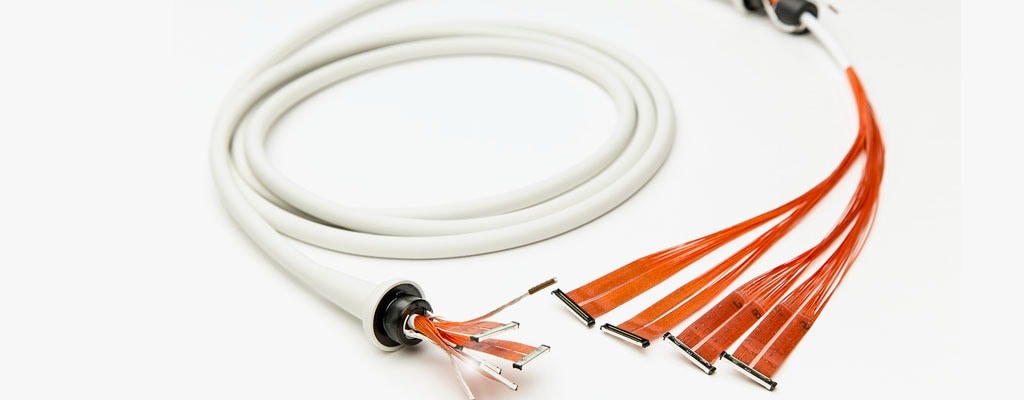

- Visualization & imaging

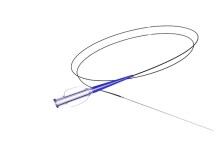

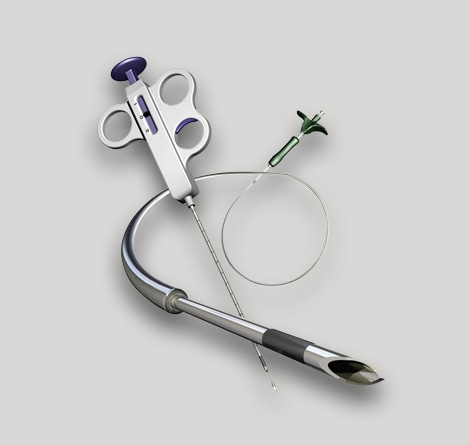

- Instrument & accessories

- Electrosurgical sets

- Connectivity components

- Surgical arms

Technical Expertise

- Developing products that can withstand high pressures, humidity, and variable temperatures, while keeping the signal integrity and avoiding moisture ingress

- Designing components that’s flexible with your needs, combining high performance, light weight, and ergonomics

- Extensive knowledge in material science to partner with customers to meet their specifications for sterilization and biocompatibility

- In-house testing for design validation, sterilization, environmental and other testing to your exact product and regulatory needs. Our experts can also support high speed signal modeling and analysis, flex testing, and thermal modeling and analysis

- Manufacturing process expertise in: stamping, laser processing, precision machining, precision & high-volume molding, and silicone molding

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e