Driving Tech Innovation in Customer Industries

Our engineering leaders partner with customers worldwide to design next-generation technology. Together, we develop the robust, rugged solutions enabling fast, efficient, and reliable connectivity in data, power, signal, and wireless systems.

Our engineering leaders are committed to helping customers achieve business value through innovation in engineering, manufacturing, and materials. As the most technically accomplished members of our engineering community, our Fellows, Chief Technology Officers, and Subject-Matter Experts serve as mentors to colleagues and partners to customers. Their specialized capability and knowledge enables them to play a crucial role in leading the development of technology that is making the world safer, sustainable, productive, and connected.

Engineering Fellows

Bert Bergner

Fellow, Automotive

Bert is a subject-matter expert in automotive data connector design, RF signal integrity, and electromagnetic compatibility (EMC) engineering. He currently focuses on innovations and products for future in-vehicle data architectures.

Engineering Specialty

RF engineering, EMC, and simulations

High-speed signal integrity modelling

RF connector design

Automotive data transmission

Data connector tests and qualification

Focal Applications

Automotive data connectors

RF connector test methodologies

In-vehicle data architectures

Physical layer design automation

Ask Bert About

RF data transmission

Signal integrity and EMC engineering

Automotive data transmission protocols and connector test methods

Career Highlights

31 granted patents

OPEN Alliance Inc. Technical Committee 9 Chair

Isabell Buresch, PhD

Fellow, Automotive

Isabell specializes in evaluating and developing new material systems and coatings that make connector contacts and terminals more reliable and fit for future purpose. Her three decades of professional experience in surface and plating technology enables her to understand the intricacies of producing materials cost-efficiently using sustainable manufacturing processes.

Read Q&A with Isabell on innovation in automotive connectivity.

Specialty

Developing materials for contacts used in automobile systems

Analyzing production for more efficient, cost-effective processes

Ask Isabell about

Plating and joining technologies

Analyzing materials and surfaces

Base materials and metal substrates, material systems, and coatings

Achievements

24 patents

More than 60 articles authored

Markus Gutmann

Fellow, Industrial Automation & Electrification

Markus specializes in electro-mechanical switching solutions such as relays and contactors, with expertise in contact physics, contact kinetics, and contact metallurgy.

Specialty

Power switching

Manufacturing process technology

Developing innovative and efficient engineering teams

Focus

Industrial automation

New energy

Functional safety

Home and building automation

Smart switching solutions

Ask Markus about

Electromechanical relays and contactors

AC and DC switching

Safety applications (force guided relays)

Hybrid switching

New product development

Design for manufacturing

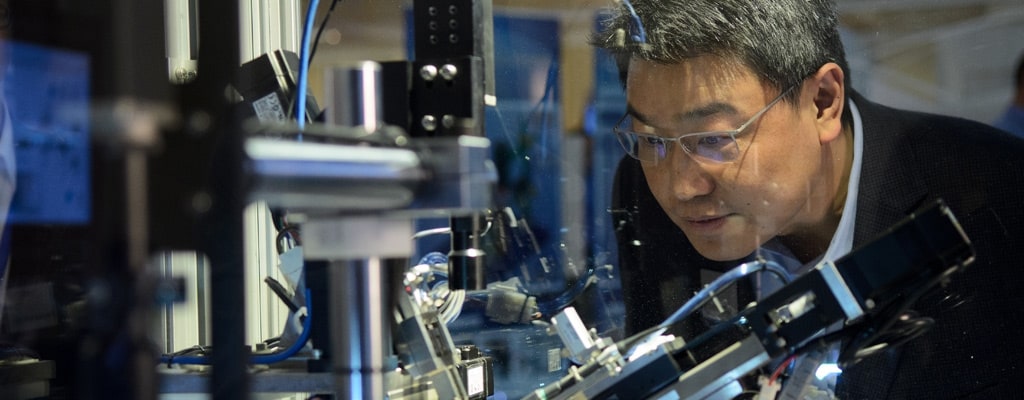

Vincent Huang

Fellow, Digital Data Networks

Vincent specializes in designing, testing and analyzing signal integrity (SI) performance of high-speed inter-connects.

Specialty

Signal integrity

High speed connector modeling

High speed connector simulation and post-processing

High speed connector testing and calibration

Connector SI tolerance analysis

Applications

Data communication

Electromagnetics

Waveguide

Passive components

Modeling and FEM simulation

Ask Vincent About

Signal integrity

CT scan and cross-section

S parameter and post-processing

Electromagnetic field

PCB SI

Dielectric WaveguideVector network analyzer

In-fixture calibration

Material, surface roughness

Sean Lewington

Fellow, Energy

Sean specializes in the development & design of new high-performance materials for harsh environments that make cable accessories & other insulating products more reliable, easier to install, longer lifetime & future proof. His many decades of professional experience in material science & technology enables him to understand the complexity of designing materials for cost effective & sustainable manufacturing.

Read Q&A with Sean on solving for innovation in energy performance.

Specialty

Designing anti-tracking/hydrophobic elastomeric & polymeric formulations for the power industry. Failure analysis & problem analysis methodology. Silicone rubber technology

Patents

6 patents

Ask Sean About

Silicone rubber technology

Design of materials for harsh environments

Sealants & adhesives

Failure analysis & problem solving

Rodney Martens

Fellow, Materials Sciences

Rod is a subject matter expert (SME) in electrical contact finishes, tribology, reliability, and currently focuses on open innovation research with universities and research institutes to meet TE’s current and future technology needs.

Engineering Specialty

Electrical contacts

Reliability and Failure Analysis

Carbon nanotubes and graphene

University and Research Institute Collaboration

Focal Applications

Tribology and corrosion of contact finishes

Reliability

Open Innovation

Webinars with and Articles Authored by Rodney

“Using Graphene to Improve Electrical Contacts”

Over 50 publications in journals and technical conferences

Career Highlights

18 US patents, 1 National Science Foundation grant

Director, IEEE Intensive Course on Electrical Contacts

Matt McAlonis

Fellow, Aerospace

Matt specializes in solving for power and signal connectivity, especially when it involves high-speed connectors, PCB interconnects, compliant pin technology, and VME/VPX system solutions.

Read Q&A with Matt on solving for connectivity in aerospace.

Specialty

Rugged connector designs for aerospace

Applications

Spacecraft (manned and unmanned)

Aircraft (manned and unmanned)

Ask Matt about

Connector solutions for VPX architecture

Read Articles Authored by Matt

Imagining the Future of Flight

Interviews with Matt

Technical Path for eVTOL Technologies (Part 1)

Bernard McDermott

Fellow, Medical

Bernard specializes in the design and development of interventional medical devices and device components at TE. He works closely with customers to provide high performance, cost-effective, novel, and manufacturable solutions from conception to production. A subject-matter expert in structural heart therapies and devices, Bernard also has extensive experience in electrophysiology, cardiovascular, neurovascular, peripheral and endoscopic devices.

Bernard is a member of the advanced technology group, whose key role is to take a long-term view of the future of medical device developments to identify and develop technologies that our customers will need in the coming years. In addition to nearly two decades of experience in medical device innovation and rapid prototyping groups, Bernard also has an extensive experience in other areas, including high-volume electronic device manufacturing and thermal design.

Engineering Speciality

Braided, hypotube or hybrid-based device design

Laser cut hypotube component design

Device simulation

Sensor integration

Design for manufacturing

Novel additive manufacturing processes

Focal applications

Smart devices

Next generation devices and constructions

Novel automated manufacturing processes

Ask Bernard about

Structural heart therapies and current devices

Future trends in interventional therapies

Component and device design

Design for manufacturing

Robert Moore

Fellow, Aerospace, Defense, & Marine

Robert specializes in solving and providing data and power solutions in the harsh

environments experienced in space, commercial and military aerospace, land, and

marine applications.

Specialty

High-speed data communications over copper, EWIS, and EMI mitigation.

Focus

Aerospace including spacecraft, manned and unmanned flight, ground systems, and copper solutions

Ask Robert About

High-speed communications, EMI mitigation, and EWIS.

Articles by Robert (links direct to another website)

"What EWIS Is and Why It Matters for Wiring Aircraft" - Aerospace Tech Review

"Commercial Protocols and Aerospace Cabling" - Assembly Magazine

Chad Morgan

Fellow, Digital Data Networks

Chad specializes in analyzing and designing high-speed, high-density components, as well as in developing signal integrity modeling, simulation, and measurement methods for characterizing digital and RF components. He is also focused on characterizing advanced conductor and dielectric materials electrically for high-speed signal transmission.

Read Q&A with Chad on solving for connectivity in data centers.

Specialty

Electromagnetic interconnect modeling (FEA, TLM)

Full system simulation (SPICE, linear, convolution)

Component and system verification testing (TDR, VNA, BERT)

High-speed network analyzer measurement & de-embedding

High-speed right-angle and direct-plug orthogonal designs

Low-skew geometry modeling & novel solutions

Applications

Data center architectures (routers & switches)

Server architectures & disaggregation

Wireless backbone digital applications

High-speed, high-density digital component modeling

High-speed, equalized system simulation

Metal & dielectric electrical characterization at high frequency

External 28-112 Gbps cable assemblies (QSFP, OSFP, QSFP-DD)

Internal low-loss cable assemblies (Sliver cable assemblies)

Cabled backplane solutions (cabled STRADA Whisper connectors)

Ask Chad about

Choosing tools and methods for predicting performance

Achieving low insertion loss and crosstalk to 50 GHz

Removing unwanted resonances from components

Measuring high-frequency material characteristics

Selecting materials for high-speed

Marjorie Myers

Fellow, Automotive

Marjorie specializes in connector contact material, physics, plating, treatments, and performance to analyze, develop, evaluate, and introduce new advanced contact approaches and processes for TE products.

Engineering Specialty

Contact physics/function – electrical and mechanical

Material and performance analysis

Plating process

Focal Applications

Connection performance analysis and development (platings, treatments, finish systems)

Training development

Advanced automotive development

Professional Accomplishments

50+ publications, both internal and external

13 patents granted

Anil Kumar Ramsesh, PhD

Fellow, Industrial Automation & Electrification

Anil is a multidisciplinary problem solver with experience in applied research, technology development, and knowledge-based lean product development. His three decades of experience in research and product development enables him to understand the complex multidisciplinary product designs, customer needs, and provide solution. He is a passionate mentor and teacher and well-connected with universities, which enables him to support TE’s talent and technology needs.

Areas of Engineering Specialty

System design: Electro-mechanical, electrical, and electronics

Design of mechanisms, drives, signal conditioning, power supply, modelling, design for EMI / EMC and testing

Sensor design, selection and fusion

Data analysis and interpretation. AI and ML algorithm for prediction

Testing and characterization: Electroanalytical methods (Voltammetry, Amperometry, Electrical Impedance Spectroscopy, Tafel plots, etc.)

Focal Applications

Smart devices, IOT, and IIOT

Sustainable processes and materials

Drive Innovation, develop and mentor key technical talent

Ask Anil About

End-to-end multi physics system modelling and problem-solving

Sensor fusion and IOT system

Electrochemical and Tribological test methods

Design for EMI, EMC, and ESD

Design for high temperature, pressure, and harsh environment applications

Career Highlights

25 Publications

8 patents granted

Co-author, ‘Micro Grid Architectures & Maintenance’, LAP LAMBERT Academic Publications GmbH & Co. KG, Germany. ISBN 978-3-659-27797-9, 2012

Josef Sinder

Fellow, Transportation

Josef specializes in process improvement and process innovation in stamping, plating, molding and assembly.

Read Q&A with Josef on solving for improvements in manufacturing processes.

Ask Josef about

Manufacturing and automation

Stamping dies

Injection molds

Digital factory

Bill Weeks

Fellow, Corporate Technology

Bill helps customers solve for high-speed, ruggedized, small form factor and low-cost optical transceivers.

Read Q&A with Bill on solving for connectivity in technology.

Specialty

End-to-end networking solutions for high speed communications

Applications

Aerospace systems

Transportation systems

Medical devices

Fiber optic sensing

Ask Bill about

Fiber optics

High speed communications

Networking - all types

Emily Zhang

Fellow, Global Operations

Emily specializes in automation manufacturing technologies and AI innovations and solutions to serve TE’s manufacturing processes.

Areas of Engineering Specialty

Automation Manufacturing Technologies

AI Technologies

Robotics and Machine Vision

Focal Applications

Process Automation

AI & Machine Vision

AI Process Control and Optimization

Robotics

Ask Emily About

Automation

AI Applications in Manufacturing

Robotics and Machine Vision

Career Highlights

216 patents granted in 14 countries

24+ papers published in TE internal conferences and external

journals/conferences

Chief Technology Officers

Davy Brown

VP & CTO, Transportation Solutions

Davy Brown serves as the Vice President and Chief Technology Officer for TE Connectivity’s Transportation Solutions segment since October 2024.

As the technical leader of the Transportation Solutions segment, Davy is responsible for the strategic direction of global engineering and product research and innovation within the Global Automotive, Industrial & Commercial Transportation, Sensors, and Global Application Tooling business units.

Davy joined TE in 2013 as Vice President and Chief Technology Officer of the Telecom and Wireless businesses and continued in that role after the merger and creation of Broadband Network Solutions (BNS). He then served as Senior Vice President, Research and Development of CommScope’s Connectivity Solutions business after its acquisition of BNS before returning to TE in 2017. From 2017 until 2024, Davy served as the Vice President and Chief Technology Officer for TE Connectivity’s Industrial Solutions segment.

After beginning his career at British Telecom Research Labs, he has held senior technology leadership and executive roles in various technology companies spanning the semiconductor, software, consumer electronics and telecommunications industries. He also co-founded and served as CTO of Trinity Convergence, a multimedia communications company.

Davy holds a Bachelor’s degree in Computer Science from the University of Newcastle Upon Tyne, UK.

Articles Authored by Davy

The Electrification of Everything

Interviews with Davy

Accelerating the Electrification Everywhere Evolution

Phil Gilchrist

VP & Chief Transformation Officer, Artificial Intelligence & Sustainable Materials

Phil Gilchrist has served as the Vice President and Chief Transformation Officer, Artificial Intelligence & Sustainable Materials since March 2024.

Previously, he served as the chief technical officer for the Communications Solutions segment, responsible for the strategic direction of global engineering and innovation, product research, engineering talent and digital process development within these business units: Data & Devices and Appliances.

Phil first joined TE in 2011 as Vice President and Chief Technology Officer of the Enterprise business unit, moving on to be the CTO of TE’s Datacom business unit. He then served as General Manager of Optics and CTO of Data and Devices until becoming the CTO for the Communications Solutions Segment.

After beginning his career as the Co-Founder of a technology start-up, Phil held numerous senior technology leadership and executive roles at Motorola from 1999-2011 focused on software, chipset and platform product development.

Phil holds a Bachelor’s degree (Hons) in Computer Science from the University of Stirling, Scotland.

Article by Phil

The Promise of Advanced Materials

Interviews with Phil

Developing Advanced Materials

Closing the AI Knowledge Gap

Travis Dahlstrom

VP & CTO, Medical

Travis is a technical leader with 15 years of engineering, operations, lean, supply, and project management experience. He leads a global technology team that partners with customers to develop critical medical component and device solutions that save lives.

Areas of Engineering Specialty

New Product Development

NPD Processes

PMO

Lean Manufacturing

Quality

Focal Applications

Medical Components and Devices

Ask Travis About

New Product Development

Lean Manufacturing

Project Management

Design for Manufacturing

Jamie Janawitz

VP & CTO, Aerospace, Defense, & Marine

Jamie leads a global team that specializes in the development and commercialization of next-gen power and signal connectivity solutions across the electrical, optical, and RF domains.

Specialty

Executing and accelerating product roadmaps to deliver differentiated value

Applications

Spacecraft

Aircraft

Defense (Land & Marine)

Ask Jamie about

Lean product development

The future of air & space travel

Rolf Jetter

VP & CTO, Automotive Europe

Rolf leads TE´s automotive team in Europe. His team partners with automobile manufacturers and suppliers in the European region to serve the future needs for all customers.

Areas of Engineering Specialty

New Product Development

New Technology for Automotive Applications

Metals and Surfaces for Harsh Environments

Road mapping and Skill/Talent Development

Focal Applications

E-Mobilty

Core Terminal and Connector Products

Digital Service

Ask Rolf About

New Innovations on Core Products

Transformation to E-Mobilty

Digital Transformation and New Digital Services for our Customers

Sustainable Products

Simulation

Harness Automation and New Zonal Harness Architectures

Connector and Terminal Design for Harsh Automotive Environment

Skill and Talent Development

Mihran Kireccioglu

VP & CTO, Automotive Asia Pacific

As VP & CTO of Automotive Asia-Pacific in TE Connectivity, which includes China, Korea, Japan & South of Asia, Mihran leads a cross-regional engineering team who develops connectivity solutions for Automotive with a product & value driven approach and delivering cost, quality, and time to market requirements of a highly dynamic and fast-growing Asia Pacific region.

Areas of Engineering Specialty

Complete Vehicle Development

New Product Development and Innovation

Engineering Project Management

Product & Technology Road mapping

Focal Applications

Signal and Power Connectivity

E-mobility

Data Connectivity

Ask Me About

Vehicle Development and Project Management Processes

Value Analysis / Value Engineering / Design To Cost / Benchmarking

Engineering Strategy & Resource Management

Cross-Cultural Collaboration

Product Business Plans

Articles

Rapid Innovation Puts Pressure on EV Battery Connectors (Connector Supplier)

Nick Liu

CTO, Application Tooling

Nick leads a global team that develops the application tooling solutions providing reliable and precision terminations to enable connectivity solutions across various

industries.

Areas of Engineering Specialty

Product and Process Development Engineering

Program Management

System Architecture and Platform Development Engineering

Lean 6 Sigma

Focal Applications

Crimping and Press Fit Technologies

Magnet Wire and Pin Insertions

Ask Nick About

Terminal and Connector Design

High Voltage and Data Connectivity

Cable Assembly and Harness

PCBA & Sensor Packaging

System Architecture

Alex Megej

VP & CTO, Connected Living Solutions

Alex leads a global team focused on solving for reliable connectivity in harsh environments.

Read Q&A with Alex on enabling innovation in industrial connectivity.

Specialty

Wired and wireless connectivity

Sensor systems

Ask Alex about

System design: Mechanics, electronics, firmware

Technology and strategy development

R&D effectiveness

Articles and Books Authored by Alex

The Growing Role of Cobots in Factory Automation

Integrated Microwave Sensors for Cavity-length Measurement in Machine Engineering

40+- articles and patents (see bibliography)

Interview with Alex

Designing Factory Cobots

Lisa Miller

VP & CTO, Industrial & Commercial Transportation

Lisa is a decisive and effective transportation industry executive with 29+ years of experience in product engineering and design, manufacturing, sales, business development and organizational management. She is a proven cross-functional leader in innovating and developing products and manufacturing solutions respecting customer demands in quality and cost, while securing internal objectives in overall business strategy. Lisa currently leads a global team focused on providing reliable connectivity products designed to withstand harsh environmental conditions for on- and off-highway vehicles and recreational transportation.

Specialty

Product technology strategy

Inspiring & enabling innovation

New product development execution excellence

Developing high performing teams

Design for manufacturing and assembly

Applications

Industrial and commercial transportation

E-Mobility

Data connectivity

Electromechanics

Terminals and connectors

Cable assembly systems

Ask Lisa About

Advanced driver-assistance systems (ADAS)

New product development

Product technology roadmaps

Developing people and teams

Minimum technical solutions

Design for sustainability

Customer focus

Articles Authored by Lisa

The future of autonomy for on-highway vehicles

(connectortips.com)

Ruediger Ostermann

VP & CTO, Global Automotive

Ruediger Ostermann is Vice President and Chief Technology Officer for TE Connectivity's Global Automotive Engineering business. His experience is built on a lifelong career in the field of T&C, junction boxes, and wiring harnesses in different companies and regions. His areas of specialty include vehicle electrical architecture and applications as well as engineering strategy and management. Ruediger joined TE in 2015 and has held various roles within the organization rising in the ranks from Senior Engineering Manager to most recently CTO of Asia Pacific, leading the Asia Pacific automotive engineering business with teams in China, Korea and Japan. Prior to joining TE, Ruediger held roles at SEWS-CE, Lear Corporation, Stocko GmbH & Co KG and EDM Engineering GmbH. Ruediger holds a degree in Mechanical Engineering from FH Muenster, Germany.

Areas of Engineering Specialty

Vehicle Electrical Architecture and applications.

Engineering Strategy and Management

Focal Applications

T&C core

eMobility

Data Connectivity

Articles Authored by Rudi

Software-Defined Vehicles Allow Upgrades with Ease

Interviews with Rudi

Designing Software-Defined Vehicles

Jeremy Patterson

VP & CTO, Americas Automotive

Jeremy leads TE’s automotive team in the Americas. His team partners with automobile manufacturers and suppliers in the Americas regions to serve the technology needs for all customers.

Areas of Engineering Specialty

New Product Development

Innovation

Talent Development

Strategy Development

E-Mobility Product and Technologies

Focal Applications

E-Mobility Products – High Power Terminal and Connectors, Charging Solutions, Battery Connectivity

Low Voltage Terminal, Connector, and Header Products

Ask Me About

New Product Development

Innovation Process and Cross-Functional Collaboration

Technology Roadmaps & Execution

Automotive Technologies and Market Trends

E-Mobility

Career Highlights

27 patents awarded

Thomas J. Schoepf

VP & CTO, Industrial Automation & Electrification

Thomas leads a global team that develops innovative connectivity solutions for industrial technologies.

Specialty

End-to-end customer-centric innovation

Research and development

Ask Thomas about

Industrial networks and systems

Industrial systems design

Technology and strategy development

Articles Authored by Thomas

Fueling the Future of Renewable Energy

Interview with Thomas

Understanding Future-State Renewable Energy

Corneliu Tobescu

VP & CTO, Sensors

Corneliu is a dynamic and results-driven executive in the sensor technology industry, bringing over two decades of experience in product development, engineering, and organizational leadership. Since March 2024, Corneliu has served as the VP & CTO of TE's Sensors business unit, overseeing all aspects of sensor engineering.

Corneliu joined the Sensors business unit in February 2022, as the Sr. Director for Central Technology Development. In this role, he led an international engineering organization focused on the development of MEMS sensing components for pressure, temperature, force, and vibration applications across industrial, medical, and automotive markets. He also spearheaded ASIC development and IoT sensor wireless module innovations, covering both hardware and software.

Before joining TE, Corneliu successfully led and expanded R&D organizations in the semiconductor industry, specializing in CMOS image sensors at AMS OSRAM, automotive speed and positioning sensors at NXP, and display driver ICs at Philips Semiconductors. Additionally, Corneliu was the COO of Berlinger AG, a Swiss company known for developing and manufacturing IoT-like temperature monitoring systems for vaccine storage and transportation, which included real-time data management and analysis software. Corneliu holds a Master’s degree in Electronics from the Swiss Federal Institute of Technology in Zurich and an Executive MBA from the Zurich School of Economics.

Specialty

• Leading Global Engineering Organizations – developing high performance teams

• Product technology strategy, roadmapping

• Enabling Innovation

• New Product Development Execution Excellence

• MEMS Sensing and Semiconductor Technology

• Automotive, Industrial and Medical Sensors

• ASIC Development

• IoT Sensor Solutions, Data Management and Analysis Solutions

• CMOS Image Sensors

• Display Driver ICs

• Operational Management

• Sensors and Electronics Design for manufacturing and assembly

Applications

• Transportation Sensing Solutions

• Automotive Safety Applications

• E-Mobility

• Condition Monitoring

• Motion Control

• Cobots & Robotics

• Semiconductors

• Medical Pumps

• Minimally Invasive

• Respiratory Care

Ask Corneliu about

• Sensing Technologies and IOT

• Semiconductors Technologies

• Driving Innovation and Technology Development

• New Product Development

• Product Technology Roadmaps

• Building and Leading Global Engineering Organizations

Articles by Corneliu

IoT Threat Protection Is a Shared Ecosystem Responsibility

Mike Tryson

VP & CTO, Digital Data Networks

Mike leads the global data and devices engineering team, partnering with the data centers around the world to develop their interconnect solutions and architectures.

Specialty

Engineering strategy and execution excellence

System engineering, optics, and high-speed smart materials Micro-electronics

Applications

High-speed data communications

Optical transportation

Data center architectures

Ask Mike about

System design and architecture

Optics science

Technology roadmaps

Engineering program management and best practices

Read Articles Authored by Mike

Machine Learning in Data Center Architectures

How High Speed Connectivity is Enabling IoT

Engineering Subject-Matter Experts

Aerospace SMEs

-

Karl Kitts

Senior Manager, Development Engineering

-

Robert Moore

Global Specialist & Principal Engineer

-

Martin Cullen

Senior Business Development Manager

-

Mark Benton

Mark Benton, Senior Principal Development Engineer

Data Center SMEs

-

Brian Costello

Business Development Manager

-

Lieven Decrock

Principal Electrical Engineer

-

Nathan Tracy

Principal R&D/Product Development Engineer

Defense & Military SMEs

-

Michael Walmsley

Global Product Manager, Aerospace and Defense

-

Franck Kolczak

Franck Kolczak, Business Development, Defense

Energy & Utilities SMEs

-

Christoph Lederle PhD

Sr. Dir. Product Management

-

Luis Puigcerver

Senior Product Manager, WAP

-

Alexander Eigne

High Voltage Cable Accessories Product Manager

-

Carlos Riva

High Voltage Cable Accessories Product Manager

-

Laura Hiller

Wildlife and Assets Protection Product Design Engineer

Connected Living Electronics SMEs

-

Jonathan Catchpole

System Architect, Intelligent Buildings

Industrial Technology SMEs

-

Mark Zitto

Product Engineer

-

Matt Mostoller

Manager, Development Engineering

Medical SMEs

-

Richa Anand, PhD

Product Manager, Surgical

-

Troy Brown

Advanced Development Engineer

-

Katie Devin

Product Manager, Metal Shafts, Hypotubes & Needles

-

Sheila Garza

Senior Manager, Customer Service

-

Charlie Holtan

Development Engineer

-

Steve Hsu

Engineer Manager, Polymer Tubing

-

Makiya Kimura

Manager, Product Development Engineering

-

Marie Ottum

Sr Principal Engineer, Advanced Development

-

Jamal Rezayee

Principal R&D and Product Development Engineer

-

Tommy Thao

Field Application Engineer, Metals

Subsea Production SME

-

Jeremy Calac

Product Manager, Optic & Signal Systems

Transportation SMEs

-

Mark Brubaker

Product Manager, Data Connectivity, Global

-

Paul Webb

Global Product Manager, Autosport

-

Clint Schlosser

Manager, Product Management

Transportation SMEs - Commercial & Industrial

-

Daniel Domke

Product Manager, E-Mobility Solutions

-

Eric Hoffmann

Product Management Lead, E-mobility

-

Kimmy Jin

Product Manager, E-mobility Solutions

-

Drew Reetz

Product Manager, E-mobility Solutions

Innovation Badge Program

Innovation Badge Program

Recognizing Engineering Milestones

Our 8,000 engineers innovate every day and one way they showcase their ingenuity is through the patents they obtain during their time at TE Connectivity. Our Innovation Badge Program recognizes our global innovators for their outstanding ability to generate intellectual property (IP) for TE. Since 2010, TE has recognized innovators who have reached established milestones in generating IP through identifiable physical and digital badges.

See More about Innovation at TE