TE Benchtop Terminator Product Portfolio Overview

How to Select a TE Terminator

TE has many bench top platforms and add-on options to choose from.

Understanding what wire size you plan to use can help narrow your choice.

5K Terminators

Weight:

- 77.3 kg [170.4 lbs]

Height/Width/Depth:

- 585 mm [23 in.]

- 536 mm [21.1 in.]

- 521 mm [20.5 in.]

Noise:

- 76 dB(A)

CE Approved

Features:

- Simple control panel with the ability to:

- Increase/decrease crimp speed

- Reset error codes

- Reset the batch counter

- Jog or step through crimp process at speed set using increase/decrease speed settings

Features:

- Precision Crimp Adjust

By simply resetting a dial, the operator can adjust crimp height in 0.013 mm increments over a 0.457 mm range.

Features:

- Tool-less removal of applicators and guards for quick and simple maintenance and product change over

Features:

- Up to 2268 kg [5,000 lbs] crimp force

- Capable of crimping 0.03 mm2 - 8 mm2 [32 - 10 AWG]

- Less than .4 seconds of cycle time per crimp

5K Splice Terminators

Weight:

- 77.3 kg [170.4 lbs]

Height/Width/Depth:

- 585 mm [23 in.]

- 536 mm [21.1 in.]

- 521 mm [20.5 in.]

Noise:

- 76 dB(A)

Based on our proven 5K terminator platform

Features:

- Designed to allow operators to be able to feed terminals above the crimp area

The IST terminator and applicator can terminate pig-tail splices or thru-splices consisting of 2 or more stranded or magnet wires with a combined circular mil area (CMA) of 400 - 13,000

The inverted design helps keep leads as small as possible, helping to produce a short break-out

The shorter leads offer improved post-processing flexibility, giving the customer extra room to tuck in and/or heat shrink the end of the processed leads

For added flexibility guard inserts and applicators can be changed in a matter of minutes to turn a Pig-tail splice machine into a Thru-splice machine

The splice version will simultaneously accept combinations of multiple copper magnet wires in a range of 11 - 20 AWG

Total CMA capable of being crimped by the inverted splice terminator is 400 - 13,000

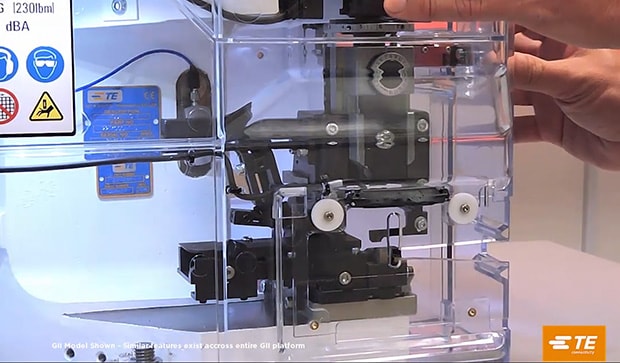

GII Terminators

Weight:

- 104 kg [230 lbs]

Height/Width/Depth:

- 520.7 mm [20.5 in.]

- 624.3 mm [24.5 in.]

- 635.2 mm [25 in.]

Noise:

- 76 dB(A)

CE Approved

Features:

- Simple control panel with the ability to:

- Reset error codes

- Adjust ram speed

- Perform split-cycle operation

- Reset air feed and batch counter

- Jog or step through crimp process at speed set using increase/decrease speed settings

Features:

- Operator friendly interior lighting

- Tool-less base plate and door designs for easy access, applicator installation and operator adjustments

Features:

- Up to 2268 kg [5,000 lbs] crimp force

- Capable of crimping 0.03 mm - 8 mm [32 - 10 AWG]

- Less than .4 seconds of cycle time per crimp

Accurate Feeding

Features:

- Split-cycle operation for proper terminal alignment above the anvil

GII+ Terminators

Weight:

- 116 kg [255 lbs]

Height/Width/Depth:

- 520.7 mm [20.5 in.]

- 624.3 mm [24.5 in.]

- 635.2 mm [25 in.]

Noise:

- 76 dB(A)

Features:

- Simple control panel with the ability to:

- Reset error codes

- Adjust ram speed

- Perform split-cycle operation

- Reset air feed and batch counter

- Step through crimp process at speed set using increase/decrease speed settings

Features:

- Operator friendly interior lighting

- Tool-less base plate and door designs for easy access, applicator installation and operator adjustments

Features:

- Up to 4537 kg [10,000 lbs] crimp force

- Capable of crimping 16 mm2 - 8 mm2 [8 - 5 AWG]

- Less than .4 seconds of cycle time per crimp

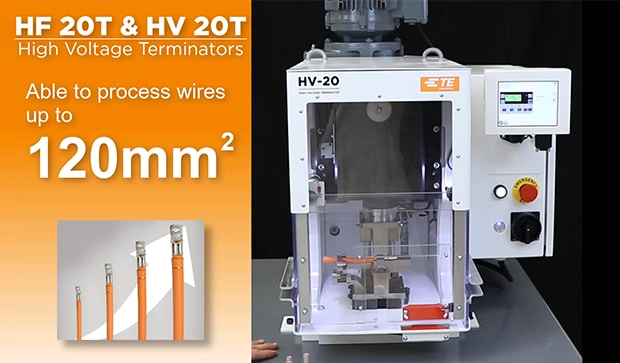

HV-20 & HF-20 Terminators

Weight:

- 390 kg [860 lbs]

Height/Width/Depth:

- 974 mm [38.3 in.]

- 552 mm [21.7 in.]

- 777 mm [30.5 in.]

CE Approved

For fast, efficient processing of high voltage cables

Able to produce up to 178 kN (20 Tons) of crimp force

- Combines sophisticated controls and traceability system

- Equipped with ethernet and USB ports to make them Industry 4.0 ready

Features:

- Operator friendly interior lighting

- Tool-less, reversible base plate design for easy applicator installation and processing flexibility

Able to process wires up to 120 mm2

Features:

- An integrated vacuum system keeps sensitive connections clean and clear of debris commonly associated with high voltage cable crimping

Features:

- An innovative modular die platform accommodates a large variety of both TE and non-TE terminals

Optional Features

Crimp Quality Monitor (CQM II)

The CQM II provides intuitive controls and detects faulty crimps, helping to improve production quality.

Crimp Quality Monitor (CQM II)

Available on the 5K, GII, GII+ and HV-20 models

Stripping Module

Accommodates end and side feed applicators

Available on 5K and GII machines

Stripping Module

Design allows for fast applicator changeover and easy adjustments.

Available on 5K and GII machines

Stripping Module

A retrofittable capacitive start sensor is available for 5K machines

Stripping Module

Module runs in three modes:

- Crimp only

- Strip only

-Strip & crimp

Defective Crimp Cut

Operators can strip the wire and crimp terminals on the same machine. The wires are stripped moments before crimping.

Available on 5K and GII machines