Water Pressure Sensors

TE Connectivity (TE) applies application expertise to design and manufacture pressure sensors and transducers for the water industry.

Various factors impact the selection and long term use of water pressure sensors and transducers in residential, commercial, and irrigation systems. TE manufactures various products with design features to offer excellent accuracy and long term stability. Below is some basic information to review before making a decision on the type of pressure sensor technology as well as the electrical and mechanical features required.

Water Compatibility

A pressure sensing element will come in contact with varying pH levels, depending on the type of water, chemicals added and the quality of the water purification process. TE packages pressure sensors using MEMS silicon strain gauges mounted onto a one piece, 316L stainless steel sensing element. 316L SS offers excellent media compatibility for residential and commercial water applications and is an NSF61 compliant material. For applications such as salt water in water maker equipment, TE offer Alloy 718 and Alloy C276 materials. The sensor diaphragm and fitting are all manufactured by machining the same piece of metal with no welds or O-rings.

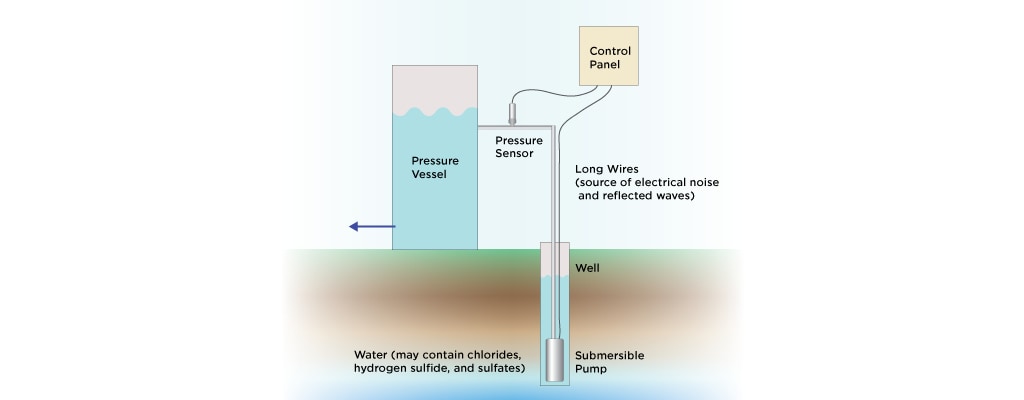

submersible water pump with pressure sensor infographic

Water Hammer

The opening and closing of valves in a system can cause a pressure transient within a water pump above the measurement range in a shock-wave. TE installs an internal, stainless steel restrictor plug. This reduces the inside diameter hole to 0.040". By reducing the ID, the pressure spike hits the face of the plug, or snubber, and feeds through the hole at a slower pace. The plug dampens the spike to continue sensor operation.

Environment

Rain, ice, dust, and pressure washers can cause water to seep into sensor housings and cause the electronics to short. TE offers sealed gauge reference pressure sensors to protect the electronics from these conditions.

Electrical Isolation

Improper grounding and lightning strikes can cause electrical failures of pressure sensors, as a result of isolation failure. TE can include custom electronics and a sensing element to withstand 500VDC isolation to work in extreme electrical conditions. The use of a 4-20mA output signal for transmission lengths greater than 15 feet in environments with electrical noise will help prevent signal loss or noisy signal conditions.