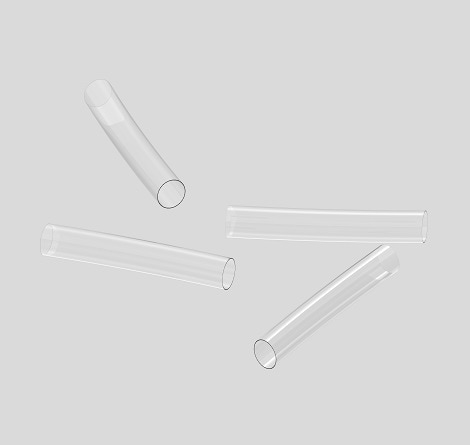

RW-175 Heat Shrink Tubing : Better Clarity With Reduced Flex Crazing

RW-175 heat-shrinkable tubing is a tough, semi rigid, very-thin-wall insulation. It is especially suitable for applications requiring high-temperature performance, outstanding abrasion and cutthrough resistance, or superior chemical and solvent properties. The translucent polyvinylidene fluoride material permits visual inspection of covered components.

/en/products/heat-shrink-tubing/intersection/knowledge-hub

Welcome to the TE Heat Shrink Tubing Engineering Resource Hub — your go to destination for engineering insights, technical documentation, and application guidance on TE Connectivity’s industry-leading heat shrink tubing solutions.

Overview

RW-175 heat-shrinkable tubing is a tough, semirigid, very-thin-wall insulation. It is especially suitable for applications requiring high-temperature performance, outstanding abrasion and cut-through resistance, or superior chemical and solvent properties. The translucent polyvinylidene fluoride material permits visual inspection of covered components.

RW-175 tubing provides electrical insulation and strain relief of multi pin connectors and solder joints. It is also widely used as insulation for high temperature components and heater leads. With its thin-wall construction, RW-175 is ideal for applications that require dense packing of components.

RW-175 provides protection from most industrial solvents, fuels,and chemicals including JP-8, oxidants, and strong acids. It is UL-recognized and CSA-certified at 150°C, 600 V, with VW-1 and OFT flame-retardancy ratings

Features

- 2:1 shrink ratio.

- Operating temperature from –55°C up to +175°C.

- Full recovery temperature: +175°C.

- RoHS compliant.

Benefits

- Tough, semirigid, very-thin-wall tubing

- High flame-resistance and high-temperature performance meets or exceeds military / industrial standards

- Microtubing sizes offered

- Protects from solvents, fuels and chemicals

- Meets NASA outgassing requirements

- Clear type has better clarity and increased resistance to crazing than previous solutions

Applications

- Appliances

- Military and commercial aircraft

- Satellites

- Commercial electronics and communication

- Industrial equipment