GET.64 Interconnection System – Enabling High-Performance Automotive Connectivity

The GET.64 Interconnection System from TE Connectivity delivers robust, sealed and unsealed connectivity for passenger and engine compartments. With a flexible 0.64mm design, low mating forces, and high vibration and temperature resistance, GET.64 meets rigorous automotive demands. Backed by in-house manufacturing and global production, it ensures quality, performance, and supply reliability worldwide.

↓

Low mating forces

HARSH

Used in harsh automotive and commercial transportation applications.

96 POS

Available from 2 to 96 positions

GET.64 Applications

- Lighting

- Power Liftgate

- Overhead Consoles

- Electronic Power Steering

- Electronic Parking Brakes

- Airbag Restraint Modules

- Adaptive Cruise Control

- Engine Control Units

- Transmissions

- Headlights

- Crash Sensing

- Intrusion System

- Passenger Sensing

- Mirrors

- Seatbelt Restraints

- Door Locks

- Inverters

- Sensors

- Radar Housings

GET.64 Product Features

- Wire-to-wire, wire-to-board and wire-to-device configurations

- 2.54mm centerline pitch

- Punch-cover configurations

- Multiple key configurations

- High range of pin count variants

- Tangle free contact offered as tin, silver and gold plating

- Female terminal accepts blades from 0.64 x 0.64mm up to 1.0 x 0.64mm

- 2nd generation thin stock receptacle accepts 1.2mm blade

- Sealed and unsealed connector housings available (straight mate or lever actuated)

- Mat seals allow high packaging density

- Design allows for specific pinout versions, no blind plugs necessary in sealed applications

- Wire dress covers

- Hand-mate and lever assist options

GET.64 Product Portfolio

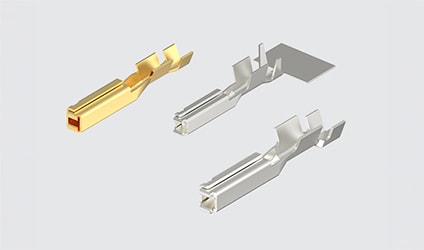

GET.64 Terminals

The GET.64 Contact System offers a compact 2.54mm x 2.54mm interface with USCAR compatibility, designed for robust, flexible automotive interconnections. With options for tin–silver, tin, silver, or gold plating, it supports up to 10 mating cycles and wire ranges from 0.22 to 1.5 mm². Its tangle-free design, CPA capability, and strong stress relaxation performance ensure easy harness handling and long-term reliability—ideal for both sealed and unsealed applications across restraint modules, control units, sensors, and in-cabin electronics.

Features

- 10 mating cycles with tin, tin-silver, silver, and gold (the only TE .64mm gold offering)

- 1-piece female terminal and 2-piece male terminal

- Supports 0.22–1.5 mm² wire sizes and up to 1.0mm blade width

- 2nd generation 'thin stock' female accepts 1.2mm blade, making the .64mm GET terminal system capable for lower power applications normally served by 1.2mm or 1.5mm systems

- Mat seal capable (female only)

- Clean body lanceless terminal using a plastic lock finger

- Class IV temperature rating for precious metals and class III for tin

- Standard (male, female) and optional reeling (male only)

- Tangle-free contact design

- Common shorting bar for all variants

Benefits

- Ensures secure and reliable mating with CPA and standardization

- Saves space while offering design flexibility

- Simplifies production with easy handling and consistent shorting solutions

- Handles thermal stress and vibration in harsh automotive environments

- Versatile for use across restraint systems, control units, and interior electronics

GET.64 Connectors

TE Connectivity’s GET.64 connectors offer a high-performance, compact solution for demanding automotive environments. With a 2.54mm x 2.54mm interface, these components are typically smaller than competitive systems while still supporting up to 10 mating cycles and 3–8A current loads across a 0.22–0.75 mm² wire range. Designed to meet USCAR Class III performance standards, they maintain 70% stress relaxation after 3000 hours at 150°C, making them ideal for both sealed and unsealed applications. CPA readiness, tangle-free contact design, and up to eight keying options enhance assembly reliability and design flexibility across restraint systems, control modules, and interior vehicle networks. Multiple pin configurations available from 1 and 2-row, 2 –96 positions.

Features

- Full line of market offerings from 2P to 96P connectors with various sizes in between and each with multiple key and pinout versions

- Sealed – wire-to-board and wire-to-device only

- Unsealed – wire-to-wire, wire-to-board, and wire-to-device

- Various single and multi-pocket header combinations in both vertical and horizontal designs

- Hand mate and lever assist options

- CPA and TPA options

- Economical shorting bar solution

- 2.54mm x 2.54mm (2nd row) and 2.54mm x 4.24mm (3rd row) centerline pitch

Benefits

- Compatible across multiple automotive platforms

- Saves space in high-density module designs

- Ensures secure and verified connector mating

- Covers both signal and low-power applications

- Simplifies harness production and routing

- Maintains mechanical integrity under thermal stress

- Durable and reliable for repeated service

- Reduces part count and tooling complexity

- Offers flexible integration with existing systems

- Suitable for sealed and unsealed automotive environments