-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

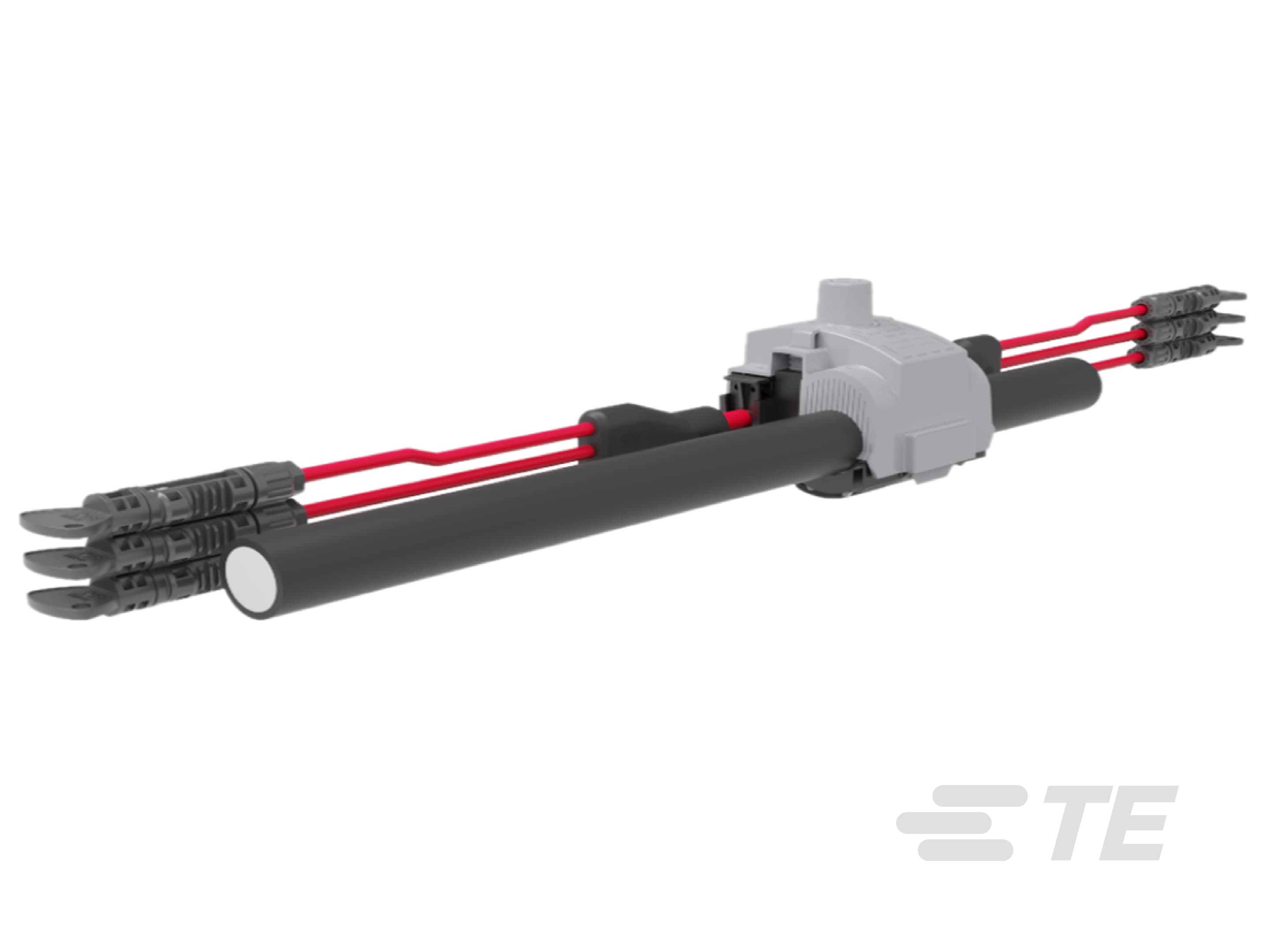

Solar IPC Assemblies IEC

Product Features

-

Solar Connector Type : Insulation Piercing Connector

-

Solar Connector Style : Piercing

-

Product Installation Type : Dead End | Mid Span

-

Wire Size (mm²): 6 | 10 – 35 | 10 | 10 – 25

Available from

Solar IPC Assemblies feature plug-and-play functionality for fast, easy installation and reliable connections. They are certified to IEC standards.

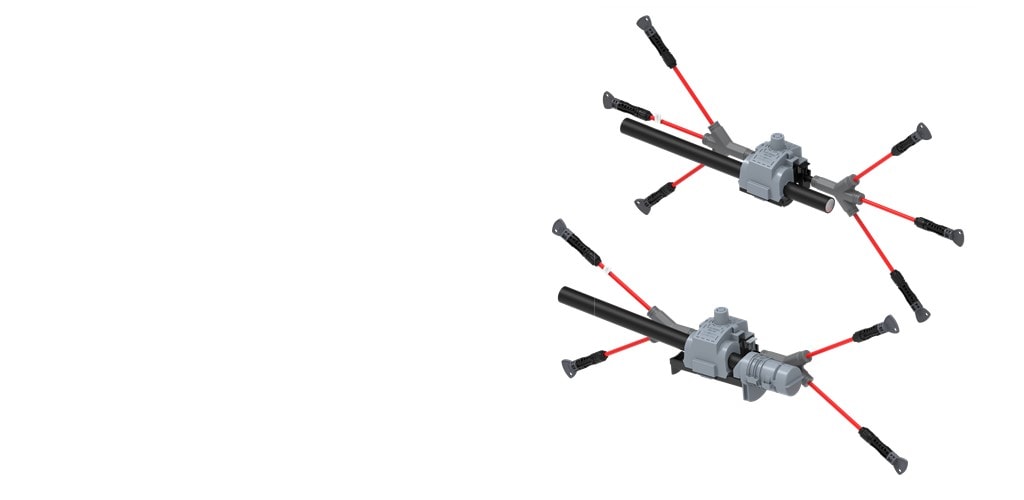

TE Connectivity Solar IPC Assemblies (SIPC) simplify PV cable connections by providing factory-assembled dual or multi-tap jumpers, which enable accurate alignment of tap cables. This enables a straightforward and safer installation process in the field. No craft labor is required to install the connectors. Designed for trunk bus ranges of 95–400 mm², they support larger array groups with fewer disconnects, reducing both material and labor costs.

The SIPC 240 and 400 are Class II connectors, as defined by IEC 61140:2001. Built with field-proven materials, SIPC assemblies ensure reliable, maintenance-free performance in harsh utility-scale solar environments.

Our SIPC assemblies incorporate TE SOLARLOK Safe Locks, which are UV-resistant, IP68-rated, and reusable. These connectors are pre-installed on all integrated tap cables to prevent unsafe connections before energization.

Key Features

- Accommodates the full range of trunk bus sizes with a single SIPC, from 95 mm2 to 400 mm2

- The multi-tap feature allows more strings per connection, optimizing EBOS architecture

- Real-time flexibility allows on-site adjustments during construction, keeping the project on schedule

- End-seal caps for dead-end applications are integrated directly into the main SIPC assemblies

- Ease of Installation: A factory-integrated multi-tap harness minimizes the need for field-installed components, improving overall reliability

Our Solar IPC Assemblies (SIPC) provide protection, insulation, and high-quality sealing for fast, secure, and reliable PV cable connections. Tested to IEC standards, they are engineered for solar EBOS applications with a robust, durable design. Watch our video to learn how to install SIPC connectors.

Question: What skillset is required to install the Solar IPCs (SIPCs)?

Answer: TE Connectivity (TE) provides clear, step-by-step instructions to facilitate simple installation and help provide a secure, reliable setup - even for less experienced electricians.

Question: Do the Solar IPC Assemblies require any maintenance after installation?

Answer: Maintenance is not required after installation. The sealed insulation piercing design prevents oxidation, helping eliminate the need for regular inspections. Watertight, UV-stable materials ensure reliable performance in humid, desert, and coastal environments. No re-tightening or recalibration is needed over the product's lifespan.

Question: What is the Quality Assurance (QA)/Quality Control (QC) process recommended during installation?

Answer: TE recommends that customers first install the SIPC assemblies without connecting the tap cables to the harnesses, then have the QA/QC team inspect the shear nut before installing the top cover.

Question: Once the SIPC is installed, can it be removed and placed in a different location?

Answer: TE recommends leaving the existing SIPC in place. Check that the protection caps are correctly installed on the ends of the tap cables, and install a new SIPC in the correct location.

Our SIPC assemblies, when fitted with PV connector protection caps on the tap cable ends, are electrically invisible to the circuit. As a result, installing them in an incorrect location has minimal impact on system performance.

Question: What are the recommended field conditions for installation?

Answer: TE SIPC assemblies are easy to install and do not require a perfectly clean environment. Installers simply need to wipe down the cable to remove debris and follow the Product Installation Instructions (PII).

Question: How reliable are SIPC connections in wet conditions?

Answer: SIPCs are IP68-rated for enhanced water and dust resistance. The sealing system prevents water and oxygen ingress, helping protect against corrosion and connection failures. They’ve been tested for 24 hours, exceeding the industry standard of 1 hour. Each tap cable passes a dielectric withstand test before assembly.

Question: What solar industry standards do TE Solar IPCs comply with?

Answer: Key certifications and tests include:

- Certifications: UL/cUL 486A/B, UL/cUL 9703, EN 62852, IEC 62852

- Water and dust resistance: IP68

- Thermal Cycle Testing: 2000+ cycles for extreme durability

- Fire Resistance: UL94 V-0 and IEC 60695-11-10/-20

- UV Resistance: F1

- Electrical Testing: 100% of cable assemblies tested before shipping

- Corrosion Resistance: Up to 1300-hour salt spray test

- Environmental Stress: Up to 1000-hour UV and temperature cycling

- Mechanical Stress Testing: Simulates real-world conditions (vibration, pressure, and physical stress)

Question: How suitable are TE SIPC assemblies for projects with different panel types?

Answer: TE SIPCs offer high flexibility, making them highly suitable for projects with varied panel types. Their real-time configurability enables the same connector to be used across the site, streamlining construction, helping reduce errors, and minimizing labor.

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Piercing Blade Base Material Tinned Copper

-

Solar Connector Type Insulation Piercing Connector

-

Solar Connector Style Piercing

Electrical Characteristics

-

Voltage Class (kV) 1.5

-

Current Rating (A) 300

Body Features

-

Cable Color Black | Red

Housing Features

-

Housing Material PA 66 Glass Fiber Reinforced

Dimensions

-

Wire Size (mm²) 6 | 10 – 35 | 10 | 10 – 25

Operation/Application

-

Power Component Application Type Above Ground

Industry Standards

-

Compatible With Agency/Standards Products EN 62852 | IEC 62852

-

IP Rating IP68

Product Availability

-

Product Availability Worldwide

Packaging Features

-

Packaging Quantity 12

Other

-

Cable Assembly Length Range (m) 95 – 240 | 240 – 400

-

Product Installation Type Dead End | Mid Span

Datasheets & Catalog Pages

- SOLAR IPC ASSEMBLIES SIPC 240/400 pdf English

Instruction Sheets

Instruction Sheet (U.S.)

- Installation Instructions For SIPC-240 and 400 pdf English

Are you sure you want to close chat?

To begin your chat with TE please enter your details