White Paper

Future-State Subsea Fiber Optics

Today's subsea fiber optic systems can deliver optical performance even at high pressures and temperatures. In the oil and gas industry, this system can meet current and future exploration and recovery challenges.

Author:

Jérémy Calac, Product Manager - Optic & Signal Systems, Marine

As offshore petroleum exploration and production seek for new ways to enhance operating efficiencies and improve recovery of petroleum reservoirs, fiber optics is being given a closer look. Fiber optics is well known for being capable of carrying higher data rates over longer distances than copper cables, while offshore drilling activity continues to migrate into deeper waters and deeper wells. At the same time, operators are pursuing real-time information and analysis of both the individual well and the entire production chain from well to delivery to the topside or land-based platform. Subsea processing and increased monitoring of the entire system means more data is generated, making the high bandwidth and longer transmission distances of optical fibers more attractive. The more information that can be gathered throughout the system, the more sophisticated the analysis becomes. The data allow not only a clear real-time picture of current conditions, but also forms the basis for sophisticated predictive modeling.

Subsea processing and increased monitoring of the entire system means more data is generated, making the high bandwidth and longer transmission distances of optical fibers more attractive.

Beyond making operations more efficient, such monitoring and analysis help companies increase the return on investment. A fiber optic system can typically be more expensive to install than its electrical counterpart. The higher initial costs of installing a fiber optic system is offset by the cost savings from long-term production efficiencies. Companies are finding that increased operational efficiencies, more and better oil and gas recovery and superior oil field management bring rapid payback. Any analysis of the cost/benefits of fiber versus copper will depend on the specific application and oil field. Economic feedback from operators is welcome information, but is rarely given to protect confidentiality of operations.

Passive Fiber-Based Sensing

Optical fibers are also becoming more attractive for permanent monitoring and the acquisition of temperatures, pressures, and other data. Optical fibers excel at creating distributed sensing systems. In this case the fiber itself is the sensor. Changes in pressure or temperature will change the backscattering profile, allowing highly accurate measurements by monitoring the backscattered light. Because the velocity of light in a fiber is well understood, the backscattered light reveals information both on the magnitude of measurement and its location along the length of the fiber. Fiber-based distributed sensing is now commonly used in the offshore oil and gas industry for several applications:

- To monitor reservoirs and retrieve in-well data to get a better understanding of what is occurring in the well

- To detect pipe leakages

- To measure temperature and prevent hydrates formation in electrically heated pipelines. Distributed sensing can be used with both direct electrical heating (DEH) or electrical trace heated pipe-in-pipe applications

- To monitor mechanical structural strains and temperatures in flexible riser/flowlines. Distributed sensing and permanent monitoring provides real time data acquisition from the complete length of the pipe

The subsea sensing system becomes entirely passive, eliminating the need to provide power to electrical sensors. Fibers can also be used as acoustic sensors in seismic exploration. Fiber optics is not necessary the universal answer. On reservoir surveillance applications, for example, the fiber systems are not replacing standard electrical communications systems – except for extreme temperature needs of 150°C or above, where copper-based sensors cannot survive. Even so, fiber systems provide additional and complementary sensing capabilities. Despite the advantages of fiber optics technology in information-carrying capacity and sensing, adoption has not been as rapid in subsea oil production as in other industries. Optical fibers are seen as fragile, but in reality it is very robust. When recommended installation practices are applied, the fiber optic system can comply with the common industry requirement of 30 years minimum life without the need for maintenance. Reliability is thus tantamount, even as equipment must withstand deepwater subsea and downhole in-well environmental conditions. At deepwater levels, temperatures are typically between 0 and 3°C, while downhole temperatures can reach 200°C. Design objectives for deepwater systems deployed as deep as 15,000 feet include the ability to withstand seawater hydrostatic pressures of 6600 psi and wellhead pressures of 20,000 psi.

Fiber Optic Subsea and Downhole Systems

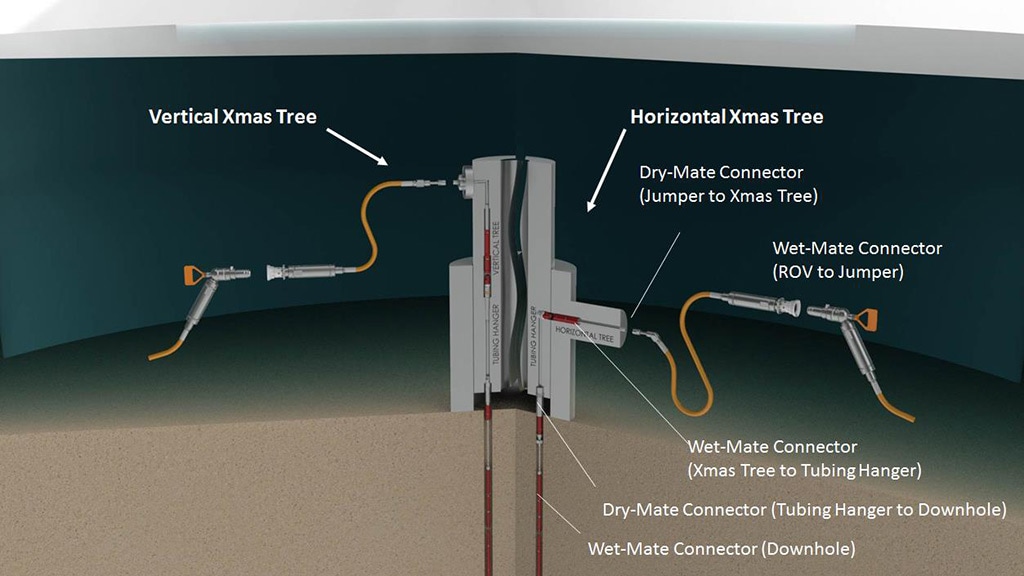

Having an end-to-end fiber solution from downhole to topside is a viable solution. The image below shows a typical system. The system atop a well is known as an Xmas tree because of the resemblance of many systems to a Christmas tree. Xmas trees can be configured either vertically (left side of figure) or horizontally (right side). With either configuration, the connectivity needs remain the same: what is called out on the right side is the same for the left side. Due to size and weight constraints, the offshore deployment of subsea systems shall be performed in multiple stages. This is why subsea smart systems use fiber optic sensors, cables and connectivity solutions (junction boxes, dry-mate and wet-mate connectors).

A simplified view showing the end-to-end optical connectivity of a typical system.

The primary function of this combination of systems is to provide optical continuity between fiber optic sensors installed either in the well or on seabed and topside data acquisition systems. A secondary but more critical function is pressure-containment to guarantee system integrity against external harsh environment. For ease of installation fiber optic connectors are required to provide optical links between subsea modules. Systems are often deployed as separate modules that are integrated on the sea floor. Dry-mateable connectors are used either within a module or between modules that have been assembled topside. They are not designed for submerged mating, although they withstand subsea water and pressures while mated. As shown below, dry-mate connectors will be familiar to users of military/aerospace circular connectors in their use of precision ceramic ferrules.

Wet-mateable connector (see below) can be mated topside, but their primary purpose is to be connected subsea after deployment by remotely operated vehicle (ROV), diver, or actuation systems. They enable modules to be interconnected in situ. Wet-mate connectors are more complex in design than dry-mate connectors. The need exists to maintain a sealed interface for both mated and unmated connectors, which is challenging given deepwater pressures. In order to maintain insulation throughout operations and over the design life, the connector is oil filled and pressure balanced. A bladder or piston mechanism equalizes the internal pressure of the connector to the outside water pressure. This allows no differential pressure across the seals and wipers.

Related to optical connectors are fiber optic penetrators, which have been developed to achieve sealing integrity from an external environment or to separate different chambers while providing optical feed-through capability. Related to optical connectors are fiber optic penetrators, which have been developed to achieve sealing integrity from an external environment or to separate different chambers while providing optical feed-through capability. Penetrators are rated for withstanding differential pressures – 5000 psi, 10,000 psi, and 15,000 psi – when linked to the reservoir pressure. When possible, subsea modules are pressure balanced – i.e., fluid filled, with the fluid being adjusted at the same sea pressure as outside the module. This allows for thinner walls, reduced weight, and higher reliability as seals are not required to withstand differential pressures. Some modules, such as those containing electronics or other devices, cannot withstand pressure higher than atmospheric. Therefore, a fiber optic penetrator is used to prevent the modules from being flooded with water. On other devices, such as subsea pumps and wellheads, which are potentially exposed to the reservoir shut-in pressures, pressure ratings can get up to 15,000 psi combined with high temperatures. The penetrator serves an environmentally important function: An optical failure would mean a loss of sensing capability, but a mechanical failure would release fluids from the well into the environment.

Strong Cables Protect Fibers

While fibers have high tensile strength to withstand longitudinal pulling, they can be easily broken or damaged if not protected correctly. As a result, fiber-optic cables typically have their own armoring. While aramid yarn – the same strength members common with other fiber-optic cables – are used, more robust designs also use metallic armoring. The high hydrostatic application pressures can increase attenuation in a fiber. TE offers three different approaches:

- Fiber in Steel Tube (FIST), which places the fiber in a solid stainless-steel tube to protect against hydrostatic pressures, high temperatures, and corrosive environments. FIST packaging is a loose-tube design, which can accommodate several fibers loosely held within the tube and encapsulated in gel. Because the fibers ‘float” within the tube, the length of the fiber is slightly longer than the tube to ensure low strain. FIST technology is the simplest and lowest cost approach. It maintains low strain on the fiber by decoupling stress on the tube from that on the fiber. If the cable stretches during installation or use, the excess fiber can accommodate the stretching without being strained. Loose tube designs also are very forgiving of extreme temperature excursions, but are less suited to the most rugged applications, such as extreme depths and extreme cable lengths. FIST also offers high density packaging of multiple fiber in the tube and, of the three options, is the easiest to terminate.

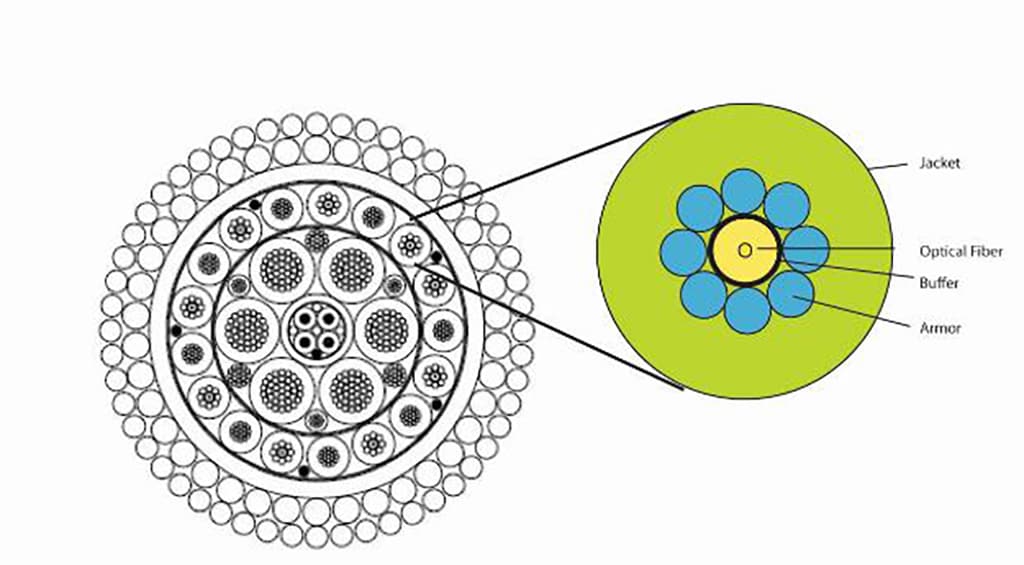

- STEEL-LIGHT armoring, which uses strands of precisely sized plow steel concentrically arranged around the fiber buffer to protect the fiber from breakage. Image below shows a STEEL-LIGHT armored fiber within a hybrid electrical-optical cable.

- ELECTRO-LIGHT armoring, which is similar to STEEL-LIGHT armoring but uses copper in place of steel. The copper can also be used for power to allow composite cables to be designed with a smaller outside diameter.

TE's STEEL-LIGHT armored fiber within a hybrid electrical-optical cable.

STEEL-LIGHT and ELECTRO-LIGHT fiber elements are both tight buffered approaches to packaging. Tight buffering, while requiring more careful manufacturing, provides better performance in highly dynamic applications and is the most rugged choice. STEEL-LIGHT armoring is the most rugged, designed to withstand hydrostatic pressures of 10,000 psi. Both STEEL-LIGHT and ELECTRO-LIGHT fibers have very small diameters, allowing them to be fit into interstices in the cable design. With some of the newer small-diameter umbilical cables using thin-wall copper conductors, such spaces may not be available. FIST may be a better choice to minimize cable diameter in such cases.

Bright Future for Fiber

The recent uncertainty in the oil market highlights the need to increase production efficiencies. Evolving technologies not only enhance oil and gas production, but also provide access to new resources to manage and extend lifetime of an offshore oilfield. The information provided by sensors gives operators unprecedented insight into conditions and allows real-time adjustment of operations and in long-term predictive modeling. Successful fiber optic pilot systems have been deployed within the last decade. They provide valuable data – and offer steady optical performance even at high pressures and temperatures. We believe in a wider adoption of fiber optics in the oil and gas market because it is an excellent tool for meeting current and future exploration and recovery challenges.