Conductive Elastomers

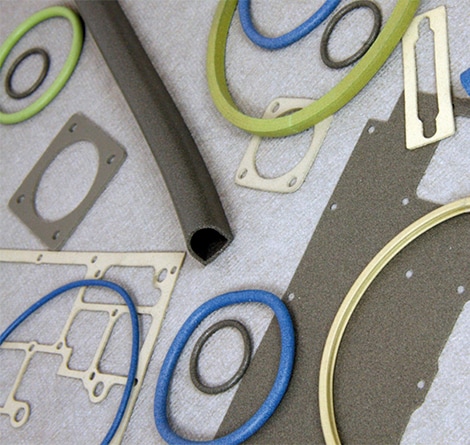

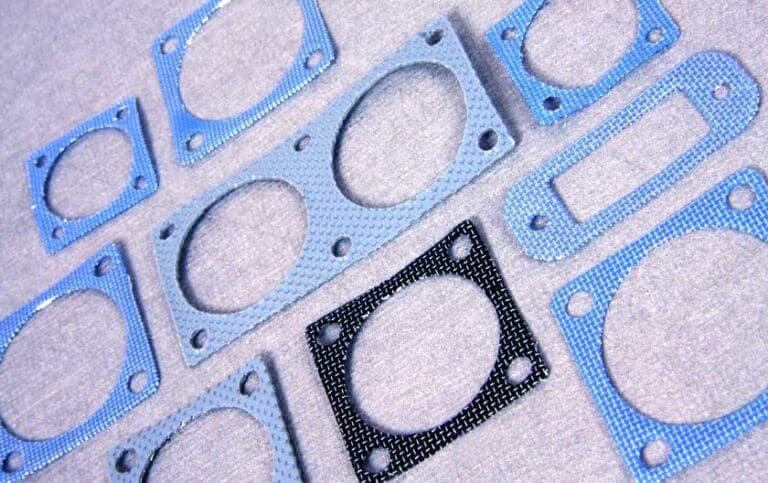

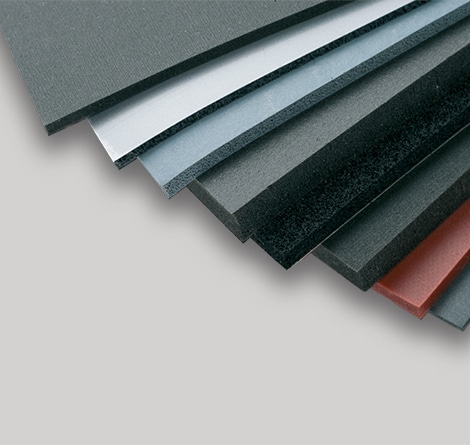

Conductive Elastomers are fully cured silicones or fluorosilicone loaded with electrically conductive particles providing superior EMI/RFI shielding performance combined with excellent environmental sealing. The various conductive fillers are designed to ensure galvanic compatibility whilst providing low contact resistance between mating surfaces.

Conductive elastomers provide superior EMI shielding, electrical conductivity, and environmental sealing for critical applications. Designed for industries like aerospace, automotive, telecommunications, and electronics, our high-quality elastomers ensure optimal protection against electromagnetic interference (EMI) and radio frequency interference (RFI) while maintaining flexibility and durability.

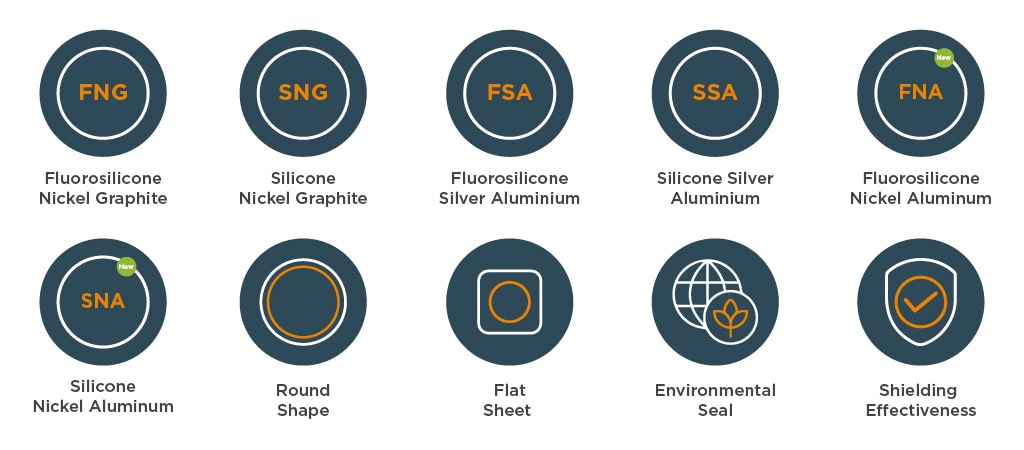

Conductive Fillers available for silicone and fluorosilicone

- Nickel Plated Graphite: A high quality cost effective commercial material with increased use in the military markets. Easily extruded or moulded. SNG FR grade to UL94 V-0.

- Silver Plated Aluminium: An excellent grade high performance material widely used for higher frequency applications in the commercial and military markets. Lighter in weight than some other materials.

- Nickel Plated Aluminium: This material offers the best corrosion performance with aluminium metalwork and a high degree of shielding effectiveness with test data up to 40 GHz.

Design Considerations

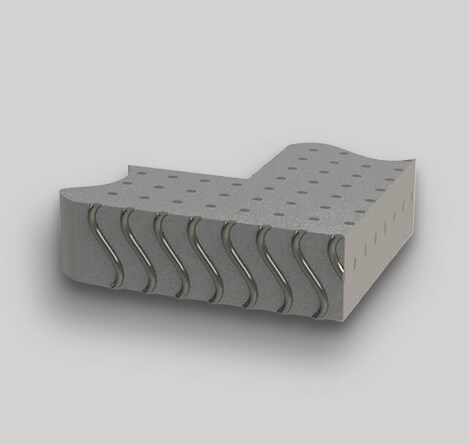

- It is important that this material is not over-compressed. If the design of the equipment does not allow for any mechanicalmethod of preventing over-compression, the gasket should be fitted with built-in compression limiters, either metal stops fitted to the gasket, or metal collars fitted into each fixing hole.

- The material is not suitable in sliding applications.

- Recommended compression: 10% to 20%.

- Self-adhesive backing (conductive or non-conductive) is offered as an assembly aid only.

- Fluorosilicone: self-adhesive backing is not recommended for use with this type of elastomer.

- Minimum material width should not be less than 2mm or at least the material thickness in any part of the gasketIf this cannot be achieved around fixing holes consider using a slot. Particular attention is required if specifying compression collars in holes.

- Consideration must be given to compression forces, hole centres, size and number of fixings and rigidity of mating flanges.

- Integral compression stops or collars should be considered to limit over compression if external controls cannot be applied.Recommended minimum sheet thickness for integral limits is 1.5mm.

Features & Benefits

- Highly conductive EMI/RFI gasket and environmental seal

- Performs in wide temperature range -55˚C +160˚C

- Fluorosilicone for harsh environments: Fuel oils and solvents

- Choice of materials for galvanic compatibility

- Flame retardant UL94 V-0 rating (molding grade only)

EMI Shielding Engineering and Technical Resource Hub

Welcome to the resource hub for our advanced performance materials portfolio, featuring cutting-edge solutions in EMI shielding. Whether you're seeking to enhance electrical insulation, environmental protection, or electromagnetic interference mitigation, our comprehensive collection of whitepapers, brochures, videos, and solution guides is designed to support engineers, designers, and decision-makers across industries. Dive into our expertly curated content to discover how our innovative materials can elevate your applications with reliability, efficiency, and precision.

Features

Conductive Elastomers Featured Products

Electromagnetic Interference Shielding Whitepaper

Electromagnetic interference (EMI), also known as radio frequency interference (RFI), results when an outside source causes noise or interference in an electrical path or circuit. Shielding is necessary to prevent EMI from causing electronic devices to malfunction.

Download NowKemtron Ltd., now part of TE Connectivity Extended product portfolio

Contact information

United Kingdom

Phone: +44 (0) 1376 348115

Email : info.braintree@te.com

France

Phone: + 33 (0) 160778316

Email : info.braintree@te.com

Germany

Phone: +44 (0) 1376348115

Email: info.braintree@te.com

Rest of Europe

Phone: +44 (0) 1376348115

Email: info.braintree@te.com

Asia

Phone: +44 (0) 1376348115

Email : info.braintree@te.com