-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples (with Business email address)

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

- Bulk Order Purchasing

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Product Listing

This product is not currently available. For more information, including distributor inventory, please contact us.

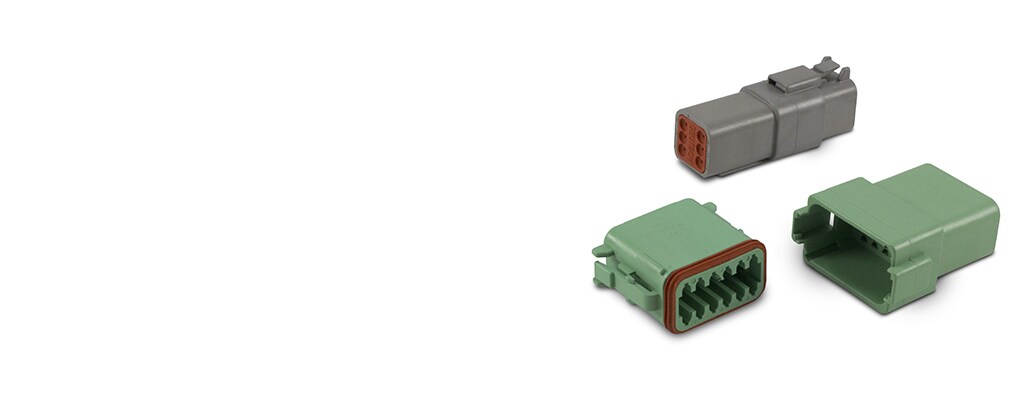

DEUTSCH DT Series Housings & Connectors

- DEUTSCH

- DEUTSCH DT

Product Features

-

Nominal Voltage Architecture (V): 12 | 24 | 48

-

Connector & Housing Type : Housing for Male Terminals

-

Number of Positions : 3 | 4 | 8 | 12

-

Sealable : Yes

-

Operating Temperature Range : -55 – 125 °C [ -67 – 257 °F ]

Available from

DEUTSCH DT housings are available in several modifications, engineered for flexibility and performance.

Series Overview

- Accepts contact size 16 (13 amps)

- 14-20 AWG (2.50-0.50 mm2)

- 2, 3, 4, 6, 8, and 12 cavity arrangements

- In-line, flange, or PCB mount

- Rectangular, thermoplastic housing

- Integrated latch for mating

- Wedgelocks confirm contact alignment and retention

- Available accessories: Backshells, boots, dust caps, gaskets, mounting clips

Learn about our field proven DEUTSCH DT, DTM, and DTP connectors for harsh environment applications. Watch this video for an overview of the connectors and for step-by-step instructions on inserting and removing contacts, as well as mating and unmating.

Additional DEUTSCH DT products

-

VIEW ALL DEUTSCH DT PRODUCTS

DEUTSCH DT connectors offer field proven reliability and rugged quality. The DT design strengths include optional flange mounting, multi-pin arrangements, and design flexibility.

Find more solutions

Frequently Asked Questions

Q: What is a DT connector?

A: DEUTSCH DT environmentally sealed connectors are designed for cable to cable, cable to board, and cable to device applications. DT connectors are used in harsh environment applications where even a small degradation in connection may be critical.

Q: What are the appropriate applications for DT connectors?

A: Truck, Bus, Off-highway, Construction, Agriculture, Mining, Emergency Vehicles, Forestry, Recreational Marine, Motorcycle

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Mixed & Hybrid Connector No

-

Connector Shape Rectangular | Triangular

-

Connector & Housing Type Housing for Male Terminals

-

Sealable Yes

-

Primary Locking Feature Integrated in Housing

-

Connector System Bus Bar-to-Wire | Wire-to-Wire

-

Connector & Contact Terminates To Bus Bar | Wire & Cable

Configuration Features

-

Blank Cavity Position 0

-

Connector Seal Code E Seal

-

Connector Modification Sealed Flange, End Cap

-

Number of Positions 3 | 4 | 8 | 12

-

Number of Rows 2

Electrical Characteristics

-

Operating Voltage (VDC) 250

-

Operating Voltage (VAC) 250

-

Nominal Voltage Architecture (V) 12 | 24 | 48

Body Features

-

Cable Exit Angle (°) 180

-

Primary Product Color Black | Brown | Gray | Green

-

Connector & Keying Code A | B | D

Contact Features

-

Contact Type Pin

-

Contact Size Size 16

-

Mating Pin Diameter (mm) 1.5 | 1.59

-

Mating Pin Diameter (in) .059 | .063

-

Contact Current Rating (Max) (A) 13

Mechanical Attachment

-

Mating Alignment With

-

Mating Alignment Type Keyed | Polarization

-

Terminal Position Assurance No | Yes

-

Strain Relief Add By Accessory

-

Connector Mounting Type Bus Bar Mount | Cable Mount (Free-Hanging) | Panel Mount

Housing Features

-

Housing Material PA GF

-

Centerline (Pitch) (mm) 4.45 | 8.7 | 9.12

-

Centerline (Pitch) (in) .175 | .34 | .359

Dimensions

-

Compatible Insulation Diameter Range (mm) 1.35 – 3.05 | 2.23 – 3.68

-

Compatible Insulation Diameter Range (in) .053 – .12 | .088 – .145

-

Product Width (mm) 36.45 | 40.51 | 40.56 | 51.5 | 54.99 | 55.12 | 88.34

-

Product Width (in) 1.435 | 1.595 | 1.597 | 2.028 | 2.165 | 2.17 | 3.478

-

Row-to-Row Spacing (mm) 4.45 | 9.12

-

Row-to-Row Spacing (in) .175 | .359

-

Connector Height (mm) 22.25 | 23.88 | 31.75 | 35.51 | 35.56 | 44.07 | 60.2

-

Connector Height (in) .876 | .94 | 1.25 | 1.398 | 1.4 | 1.735 | 2.37

-

Product Length (mm) 44.02 | 46.94 | 47.19 | 47.45 | 50.62 | 51.89

-

Product Length (in) 1.733 | 1.848 | 1.858 | 1.868 | 1.993 | 2.043

Usage Conditions

-

Operating Temperature Range -55 – 125 °C [ -67 – 257 °F ]

-

Operating Temperature (Max) (°C) 125

-

Operating Temperature (Max) (°F) 158 | 167 | 176 | 185 | 194 | 212 | 221 | 230 | 248 | 257

Operation/Application

-

Circuit Application Power & Signal

Industry Standards

-

UL Flammability Rating 12mm Flame Test per Standard UL-94 | 20mm Flame Test per Standard UL-94 | Not Tested

-

IP Rating IP68 | IP6K9K

-

Compatible With Agency/Standards Products SAE J2030

Packaging Features

-

Packaging Method Box | Package

-

Packaging Quantity 96 | 170 | 200 | 250 | 300 | 800

Other

-

Serviceable Yes

-

Connector Position Assurance Capable No

Flipbook Catalog

- Industrial & Commercial Transportation - Terminals and Connectors (English) TE's Industrial & Commercial Transportation Terminals and Connectors flipbook catalog features AMPSEAL, AMPSEAL 16, Circular DIN, DEUTSCH, HDSCS, LEAVYSEAL, and Superseal 1.0 connectors, contacts, tools, and accessories.

Brochure

- DEUTSCH DT Enhanced Seal Retention Connectors (English) When you need design flexibility and a reliably sealed, rugged connector, TE Connectivity’s DEUTSCH DT series has you covered with an enhanced interface seal retention design. English

Product Specifications

- DEUTSCH DT Connectors Product Specifications (English) This specification covers performance tests and quality requirements for DEUTSCH DT connectors.

Test Specifications

- DEUTSCH DT Connectors Test Specifications (English) This report summarizes the results of in-house qualification testing of DEUTSCH DT electrical connectors.

Connector Selector

- Connector Selector (English) The Connector Selector is a reference guide to TE Connectivity's (TE) Industrial & Commercial Transportation electrical connectors.

DEUTSCH, TE Connectivity, and TE connectivity (logo) are trademarks.

Are you sure you want to close chat?

To begin your chat with TE please enter your details