Fossil fuels and the internal combustion engine have powered the global economy for more than a century, but the future will be electrified. As the world adopts ambitious goals to combat climate change and reduce carbon emissions, engineers are racing to commercialize electric alternatives to the vehicles and machinery that we use every day.

We can see this "electrification of everything" happening anywhere that people or cargo are in motion—on the roads, rails, sea and in the air, down to the factory or warehouse floor. And while the basic concept of electric propulsion applies in each setting, specific technological issues such as battery capacity, power transfer, range and charging times vary greatly depending on the application.

As a result of TE Connectivity's decades of experience in electrical connectivity and materials science, we are working on the front lines to solve these challenges. Here are some innovations happening across major industries to enable the electric future.

Automotive: Creating Safe and Reliable Commercial Vehicles

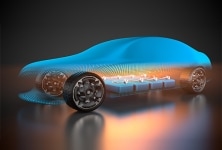

Electrification is the biggest technological change in the automotive industry since the commercialization of the internal combustion engine, and it's happening incredibly quickly. Sales of passenger EVs doubled in 2021 as engineers continue to optimize size, weight and power to extend the range of EVs. At the same time, advancements in high-power, high-speed charging and the expansion of charging infrastructure are further reducing range anxiety for drivers.

The next step in electrifying the transportation landscape is improving electric alternatives for heavy commercial vehicles like trucks and buses—where technical challenges are greater. Increased battery density for higher storage capacity and power output is essential to move heavier loads, with electric buses, for example, requiring roughly five times the battery capacity of the average passenger EV. Super-fast charging is also essential to enable rapid turnaround times needed to keep delivery and transit vehicles on schedule.

But transferring more energy from the charger to the battery and within the vehicle generates much higher heat, putting a special focus on safety within commercial vehicles. TE’s expertise in developing high-power components and cable assemblies and our focus on advanced materials for better electrical performance is helping the commercial EV industry achieve its performance requirements without sacrificing safety and reliability.

Rail: Improving Aerodynamics and Replacing Diesel Tenders

Unlike automobiles, passenger trains have been electrified for more than a century. Yet even countries with established electric rail networks are seeking improvements in speed and efficiency to enable modern high-speed trains.

We work with rail companies to improve train size, weight and aerodynamic profile through components such as our low-profile roofline solutions, which reduce drag and increase efficiency while creating more usable space within the train carriage.

The emerging technology of battery-powered tenders shows the most promise to expand electric rail to countries still running on older diesel infrastructure. Battery electric trains are already being tested in California, and continued improvement in large battery packs and rapid charging solutions will allow countries to replace diesel tenders with these cleaner battery-powered models—eliminating the significant investments needed to develop a completely electrified rail system.

Aviation: Ushering in the Age of Urban Air Mobility

Although only small, propeller-driven electric aircraft are currently available today, the aviation industry has been taking important steps toward the goal of electric aviation for years. The first phase of aircraft electrification replaced hydraulic and mechanical systems like flight controls and braking to help reduce weight and increase efficiency. Now, manufacturers are testing electric motors for taxiing to and from gates and hybrid propulsion systems that use the fuel-burning engines for takeoff and climbing but switch to efficient electric motors for cruising.

Fully electrified propulsion is enabling electric vertical takeoff and landing (eVTOL) aircraft—a completely new class of short-range air vehicles that are well-suited for air taxi services, automated freight delivery and even personal air vehicles. Once only seen in the movies, multiple companies are competing to be the first to bring their product to market, and we expect them to become mainstream very quickly. In what’s likely to be a very public showcase of the technology, Paris is planning to use eVTOL aircraft for transportation between sites at the 2024 Summer Olympic Games.

That said, the importance of optimizing for weight and power is even more critical in the eVTOL market, where operators want to maximize flying time. Adding to this complex equation is the need for full redundancy in eVTOL powertrains: Running down a battery might be an inconvenience in a car, but it's a major safety concern for aircraft. As a result, TE is working with eVTOL manufacturers to develop smaller, lighter and more reliable components to help reduce aircraft weight and increase efficiency while still achieving redundancy.

Compared to automobiles, eVTOLs will also feature a higher degree of autonomy, requiring an array of sensors that will generate massive amounts of data to guide aircraft above urban landscapes. TE's advancements in hybrid cables that combine power and high-speed fiber-optic data transfer can help manufacturers meet their bandwidth and power needs without adding weight to vehicles.

Industrial Vehicles: Creating an Ecosystem for Electric Forklifts and AGVs

A more down-to-earth transition is happening inside factories and warehouses, where industrial users are moving away from traditional gas-powered manual vehicles such as forklifts to new equipment like automated guided vehicles (AGVs). Although smaller batteries can easily deliver these vehicles' power and range requirements, the key challenge is maintaining vehicle uptime.

Forklifts and AGVs must operate nearly continuously to meet today's manufacturing and shipping demands. Therefore, plugging them into fixed charging stations for extended periods isn't a viable option. Instead, electrifying the manufacturing industry will require new, distributed infrastructure to enable fast charging, such as drive-over charging ports strategically placed around the facility floor. We're supporting this type of charging system by thinking through what it means for every component in the vehicle's electric system, such as the need for specialized charging inlets and components that are designed to help maintain high uptime.

Developing the Talent to Reshape the World

No matter the industry or end product, finding the right talent is essential for creating breakthrough innovations that will enable the electrification of everything. In addition to traditional electrical, electronics and mechanical capabilities, engineers must be skilled in designing high voltage systems that can operate reliably at extended temperatures, which in turn will require the development of new materials that will perform in these harsh environments. Designers in all fields will increasingly focus on size, weight, and performance variables that were once primarily limited to aerospace design. As manufacturers embed greater intelligence and automation into nearly every product, software skills will remain in high demand.

These emerging capabilities are why it is critical for companies like TE to have fully engaged workforce and strong professional development programs designed to stay on the leading edge of technology and customer focus. Together, we can deliver the innovations needed to realize an electric future.

About the Author

Davy Brown

Davy Brown is vice president and chief technology officer for TE’s Transportation Solutions segment. In this role, he is responsible for the strategic direction of global engineering and product research and innovation within the Automotive, Industrial & Commercial Transportation, Sensors, and Application Tooling business units. Throughout his career, Davy has held senior technology leadership and executive roles in various technology companies spanning the semiconductor, software, consumer electronics, and telecommunications industries.

Innovation in the Electrification of Technology

Executive Insights: More stories on tech innovation

e

e

e

e