Up Close with rLoop

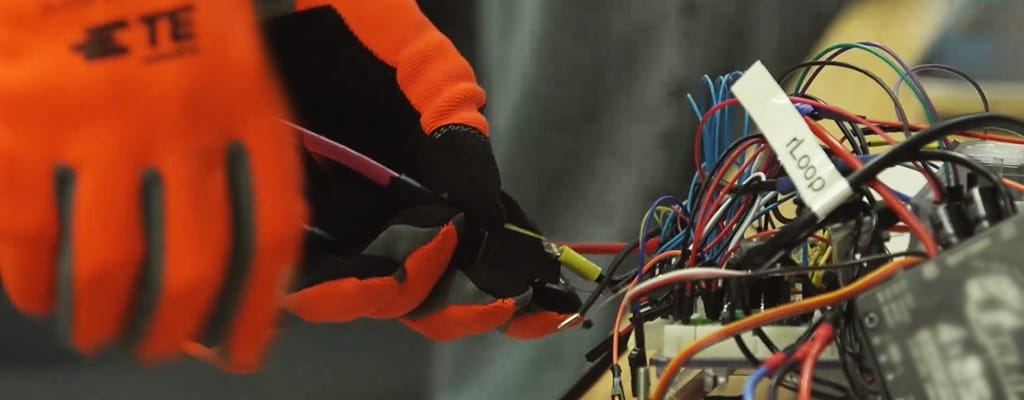

Maurizio Mercurio, TE Connectivity product development engineer and virtual advisor to the rLoop team, shares his story of joining the transportation revolution.

Inspired by rLoop's mission to create the fifth mode of transportation, Maurizio Mercurio, a product development engineer in TE Connectivity's (TE's) Industrial Automation and Control business, joined the team of rLoop TE virtual advisors earlier this year. Passionate about the project and committed to maximizing his contributions, Maurizio traveled to TE's Silicon Valley facility, home of rLoop, to assist the team with the pod build. Upon his return, Maurizio shared his experiences helping rLoop make "today's impossible, tomorrow's awesome."

Maurizio's Story

Meeting rLoop

Whether designing the first crimp solution to replace the labor intensive soldering process like the founding engineers of TE Connectivity (formerly known as AMP Inc.) did, or developing integrated connector and sensor solutions that are driving the internet of things (IoT) movement, the passion for solving the unknown connects every engineer. For our partners at rLoop, that unknown is designing the fifth mode of transportation to revolutionize mass transit. As an engineer at TE, I am constantly fascinated by the wide variety of applications we enable and am always looking to improve existing solutions or solve new problems. So when I saw TE's call for rLoop virtual technical advisors, I didn't hesitate to volunteer.

As one of TE's more than 20 virtual advisors selected to support seven engineering areas for rLoop, I was excited to be part of the project. In fact, for as much as I advised, there was even more for me to learn. I jumped in immediately—discussing over the Slack communications platform—what actuator should be purchased, participating in design reviews over Google Hangouts and reviewing 2D drawings for parts that were ready to be sent to manufacturing and more. The onboarding was a bit overwhelming due to the amount of information being exchanged between legacy team members, but everyone was willing to help me overcome any hurdle inhibiting my progress. While the experience as a virtual and remote advisor was great, I was still curious to visit the rLoop manufacturing site at TE's Silicon Valley facility. I approached my manager and shared my passion for the project, and was granted permission to travel to California to meet the team and assist with the pod build for a week in October.

"...the passion for solving the unknown connects every engineer."

Once in Silicon Valley, my schedule closely matched the rLoop team's. During the day, I worked from an office at our facility fulfilling my duties with TE, and in the evenings worked alongside the rLoop team on the rPod build. It was incredible to put a face to all those witty Slack usernames I had been interacting with over the past few months.

If you get the opportunity to visit rLoop's headquarters, you will probably run into Tom, an aerospace engineer who comes on-site as the engineering lead for almost five hours every night after he is done with daily responsibilities at his job. Amir remotely designed the entire aeroshell of the pod while saving enough money to give up his job in India and relocate to the San Francisco Bay area to dedicate himself to rLoop full-time. During the day, Frank does R&D at his full-time job and on the side works as one of rLoop's electrical engineering ninjas. If you're getting hungry after helping Ryan (the manufacturing lead) with some machining, you don't need to worry because Rebecca, the PR lead, has most likely just ordered some pizzas in between managing media opportunities and filming.

Every day I saw new faces and a wide range of tasks being crushed, from the electrical and software team working to program a scale kit of the hover engines and the manufacturing team working with PCM (phase change material) to absorb heat from the battery packs, to the mechanical engineers taking a break from riveting and trying out PlayStation's new VR headset.

Trials of an Open-Source, Online Think Tank

As a non-profit, open-source, online think tank, rLoop relies on volunteers to contribute with any skill, experience and time they are willing to bring to the table. Without monetary incentives or a stable career path, the team's progress depends heavily on each member's commitment, initiative and more importantly, their available time. rLoop team members work on the project when their regular life routines allow, and they leave when their life duties call back for their attention.

Imagine constantly bringing new people into a mature project with more than a year's worth of progress and having a tight deadline for completion – competition weekend is in January 2017. Slack and efficient document management have aided in the self-learning onboarding process for new members as it is not practical for a legacy members to divert their time to bring someone new up to speed. The onboarding process was definitely the biggest challenge for me. As a 25-year-old accustomed to the world of online tools and mobile apps, I still struggled with the steep learning curve and adapting to the different applications that were required to sync with rLoop's virtual collaborative environment.

"Imagine constantly bringing new people into a mature project with more than a year's worth of progress and having a tight deadline for completion..."

Key Learnings from rLoop

TE's initiative to support this brilliant group of global entrepreneurs in their quest to disrupt transportation is massively admirable. Just like rLoop has been receiving expertise and product support from the TE virtual advisors, there is quite a lot TE and other companies can learn from rLoop in return.

Access to information and transparency is one benefit of the team's collaborative style. Having all communications and tasks accessible to every team member allows anyone to decide where he or she can contribute. Maximizing technology and online tools to eliminate our physical and communications barriers may be the greatest key learning companies can emulate. The passion and drive to accomplish a shared goal is easily noticed among all rLoop members—something we should strive to scale here at TE. When engineers feel they're part of something larger than themselves, that satisfies individual ambitions and they tend to start viewing their "day" jobs as purpose-driven.

Working with rLoop has been an incredible experience for me. It's fascinating to work with people that are investing their personal time in something they intrinsically believe in. Most rLoop members have full-time jobs and many have families and children, inspiring me to believe that when you are passionate about something, you don't let any obstacle stand in your way—you forge ahead and find the means to pursue it.

"When engineers feel they're part of something larger than themselves, that satisfies individual ambitions and they tend to start viewing their 'day' jobs as purpose-driven."

WATCH: PROJECT FIFTH MODE

WATCH THE RLOOP JOURNEY

What's it like to work on the next mode of transportation with a crowdsourced team? How do you build a pod intended to run 700mph? Watch the rLoop team members as they take the rPod from concept to creation to competition. This five-part video series takes you inside the lab as the virtual and physical engineering worlds come together to make the fifth mode of transportation a reality.