-

Product Listing

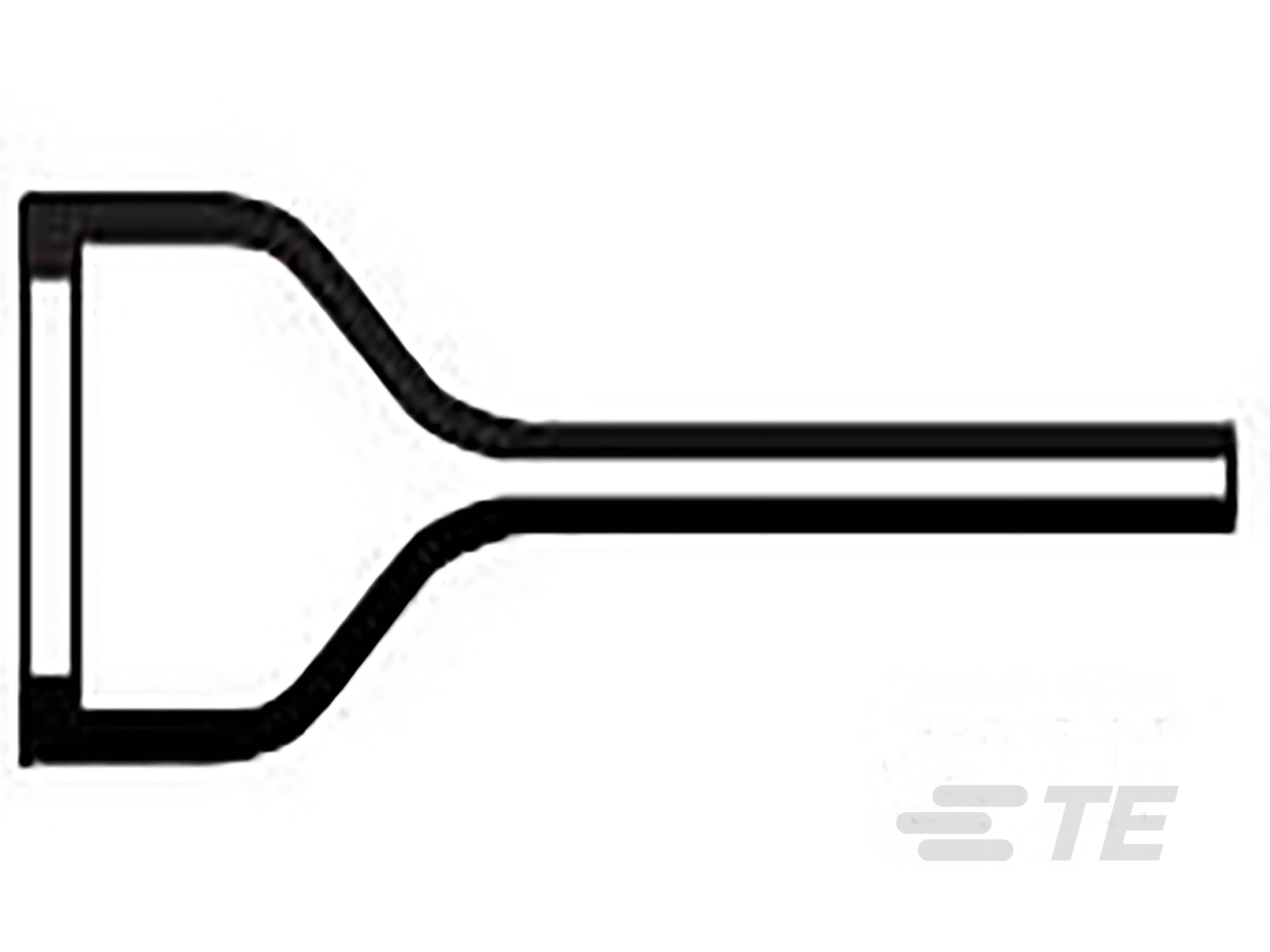

Heat Shrink Boots: Lipped, Straight

Heat shrink boots with a straight transition and lipped feature. Use with circular connectors and the appropriate TE backshell adapter to provide connector/cable strain relief.