Q: What gauge wire (AWG) will you be using?

A: TE’s HPI product accepts 22-32 AWG discrete wire. Remember that the higher the AWG measurement number, the smaller the discrete wire. For example, 32 AWG is smaller than 22 AWG will likely have less current carrying capacity.

Q: Are you transferring signal or lower power throughout your device?

A: HPI products are simple interconnect solutions that can be used to transfer signal or lower power in multiple applications across many industries

Q: Does your application have a fan, motor, switch, display, light or any other simple device?

A: HPI product may be a good solution to control these type of ancillary items.

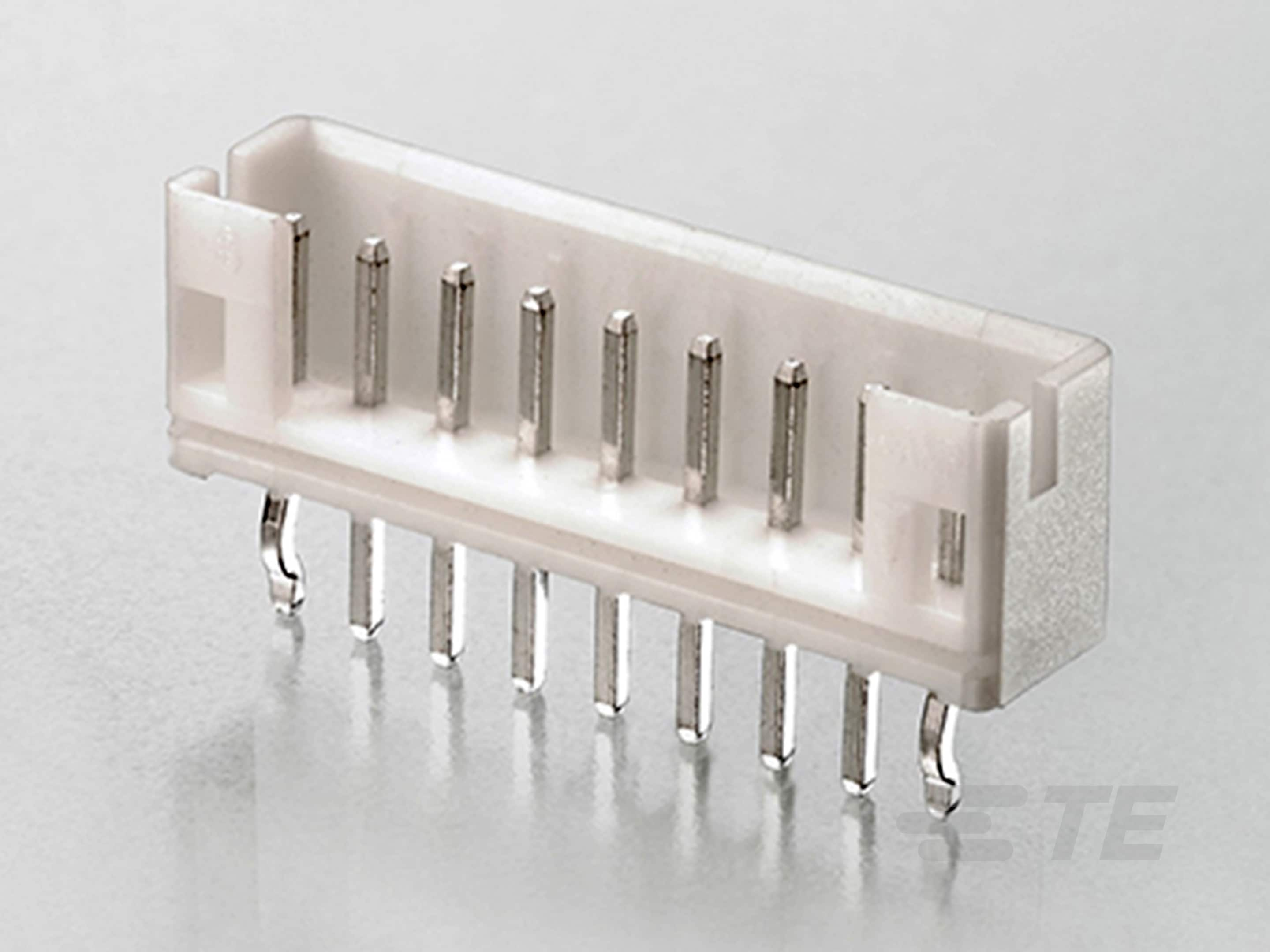

Q: Does your application require a locking feature to strengthen the mating connection between the plug assembly and receptacle?

A: If your application requires a secure mating retention feature, TE’s 2.0mm HPI product line offers an external locking feature to improve the reliability of the interconnect system.

Q: What are the technical requirements of your application?

A: It is imperative that you ask your customer the current and voltage requirements of their application. Current, which is expressed in amps, is usually the driving factor when selecting a small pitch wire-to-board product. Other information that you should consider include operating temperature, PCB real estate, profile height limitations, material restrictions, etc.

Q: What tooling is available to apply TE’s wire-to-board products?

A: TE’s tooling divisions offer a wide range of hand tools, semi-automatic, and automatic tools. Please visit Application Tooling to determine the application tooling that meets your needs.