View products below to see detailed pricing

-

Product Listing

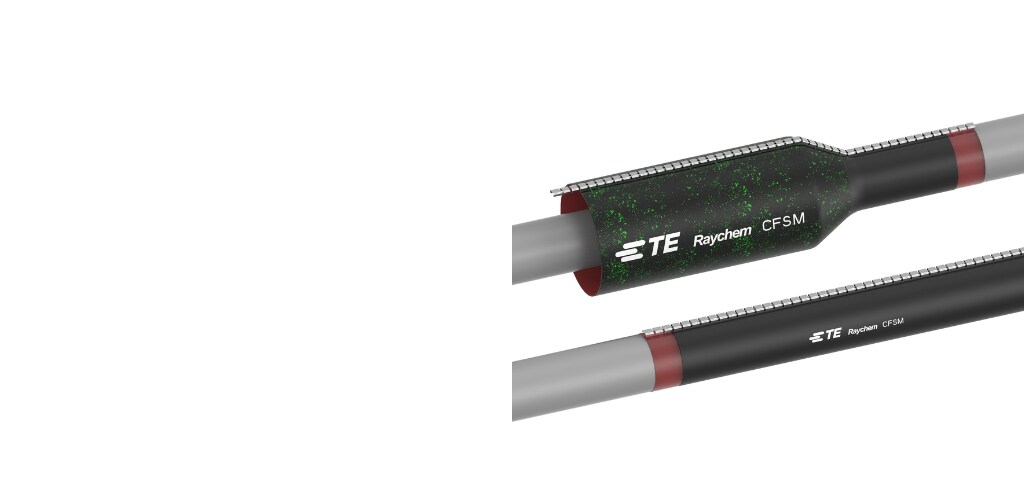

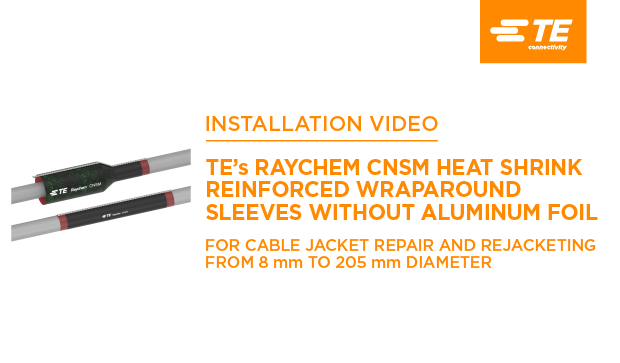

Raychem Heat Shrink Reinforced Wraparound Sleeves

- RAYCHEM

Our Raychem heat shrink reinforced wraparound sleeves are designed for cable rejacketing and sealing of low, medium, and high-voltage cable accessories. The fiber-reinforced composite structure provides excellent resistance against splits, cut-throughs, and mechanical damage. They are available with or without aluminium foil.

Product Features

-

Voltage Class (kV): ≤ 1

-

Power Cable Wrap Product Type : Cable Tap Splice | Sleeve

-

Compatible Cable Diameter (Max) (mm): 43 | 45 | 55 | 59 | 65 | 75 | 84 | 86 | 100 | 113 | 125 | 146 | 149 | 164 | 165 | 185 | 200 | 205

-

Compatible Cable Diameter (Max) (in): 1.692 | 1.771 | 1.772 | 2.165 | 2.323 | 2.559 | 2.95 | 2.952 | 3.307 | 3.386 | 3.937 | 4.449 | 4.921 | 5.748 | 5.866 | 6.456 | 6.496 | 7.283 | 7.874 | 8.071

-

Compatible Cable Diameter (Min) (mm): 8 | 12 | 15 | 20 | 22 | 25 | 30 | 33 | 34 | 38 | 40 | 42 | 44 | 50 | 55 | 61 | 65 | 71

-

Compatible Cable Diameter (Min) (in): .314 | .315 | .472 | .59 | .591 | .787 | .866 | .984 | 1.181 | 1.299 | 1.339 | 1.496 | 1.575 | 1.653 | 1.654 | 1.732 | 1.968 | 1.969 | 2.165 | 2.3 | 2.401 | 2.559 | 2.795

-

Flammability Performance : Non-Flame-Retardant