Lighter Interconnect Solutions

As the market trends towards miniaturization, FPC connectors have been developed to meet the challenges of this expanding market, which demands smaller centerline or pitch spacing, lower profile heights, and lighter interconnect solutions. TE's FPC solutions are reliable interconnects that use an actuator to secure the cable termination, and are field terminatable (require no tooling) and are available in centerline spacing of 0.25mm, 0.3mm, 0.5mm, 1.0mm, and 1.25mm, and incorporate a low profile height and light-weight features.

↓

Low profile height

$

Cost effective solution

Save Time

Features

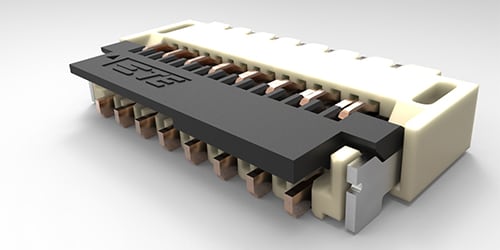

FPC Connectors

- Can accommodate FPC/FFC cable

- Available in ZIF and non-ZIF styles

- Variety of centerline spacing options

- Available in SMT and T/H PCB termination

- Requires no tooling

- Available in right-angle and vertical mounting orientations

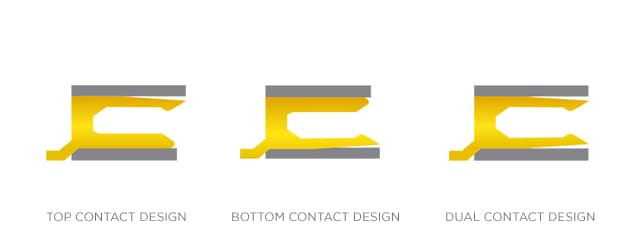

- Right-angle version available with top, bottom, or dual contact

- Solder pads and kinked legs for PCB retention

- Locking feature provides high retention force

Product Line Options

FPC Connectors

-

0.25mm pitch FPC Connectors

Centerline 0.25mm. Robust actuator, back flip-lock, bottom contact, slanted insertion.

-

0.3mm pitch FPC Connectors

Centerline 0.3mm. Variety of flip-lock types, contact points, and actuator types.

-

0.5mm pitch FPC Connectors

Centerline 0.5mm. Variety of flip-lock types, contact points, and actuator types. Right-angle and vertical orientation styles. Top, bottom, or dual contact versions.

-

1.0mm pitch FPC Connectors

Centerline 1.0mm. ZIF and non-ZIF versions. Through-hole and surface mount versions. Right-angle and vertical orientation styles.

-

1.25mm pitch FPC Connectors

Centerline 1.25mm. Non-ZIF. Right-angle and vertical orientation styles

New Products

Low Profile

Applications

FPC Connectors

- Flat flex printed cable

- LC displays

- Game consoles

- Tablets

- Wearables

- Cameras

- Inkjet, laser, and 3D printers

- Personal computers

- Mobile and smart phones

- GPS devices

- Set top boxes

- Disk drives

- Copiers

- Medical equipment

TAIL ORIENTATION

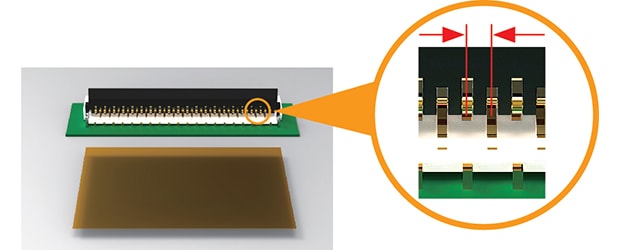

ACTUATOR TYPES

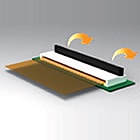

All of our fine pitch FPC connectors incorporate a flip lock actuator for greater printed circuit retention. This termination method also allows for zero insertion force, which is why this product is commonly referred to as a ZIF connector. The operation of a flip-lock actuator can be seen in the images below.

Front Flip-Lock Actuator

Back Flip-Lock Actuator

Stuffer Actuator (Plunger Style)

CONTACT TYPES

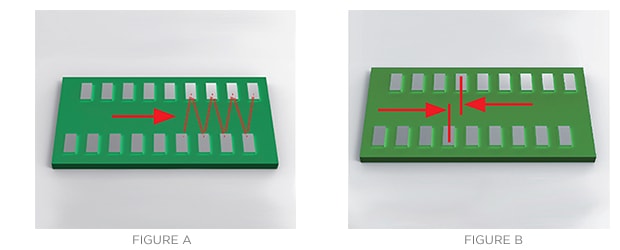

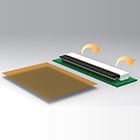

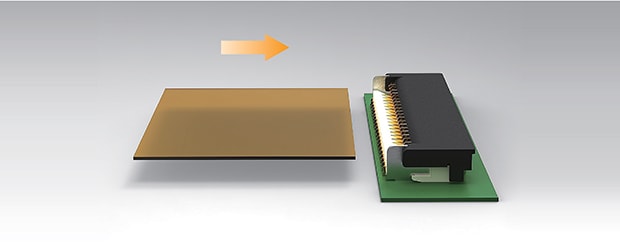

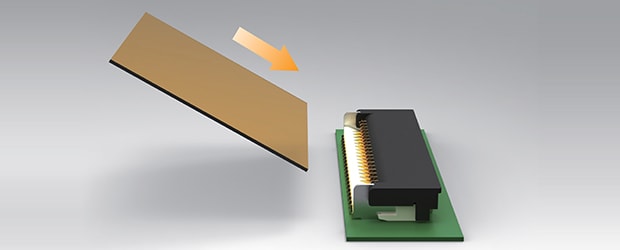

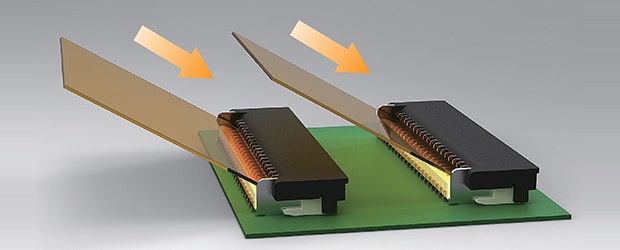

ANGLED INSERTION

Our new FPC connectors enable the design flexibility our customers need. In addition, they allow for low profile height, space savings and reduced assembly time.

- Joseph Proffitt,

- Product Manager, TE Connectivity

Frequently Asked Questions

Standard & Fine Pitch

Q: What position sizes can TE Connectivity provide?

A: We offer odd number position sizes only, unless otherwise stated on the product drawing. We can also offer up to 71P in our 0.3mm series and up to 61P in our 0.25mm pitch series.

Q: What is the advantage of angled flexible printed circuit insertion?

A: Being able to insert and mate the FPC into the connector at an angle makes it possible to mount the FPC connector almost anywhere on your PCB as there is much less clearance needed in front of the connector during mating and unmating.