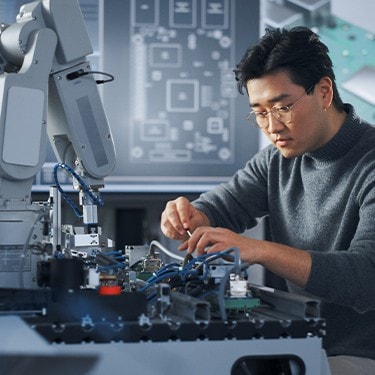

Accelerating the convergence of connectivity, data, & intelligence

We partner with customers to optimally engineer omni-connectivity solutions for the complex requirements and cross-domain intelligence enabling electrification, cloud computing and edge computing, data communications, renewable energy, and industrial automation.

Read TE Nexus - Insights on Innovation in Omni-Connectivity

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e