White Paper

The Importance of Controlling Humidity in Commercial and Residential Environments

INTRODUCTION

Humidity is defined as some measure of the water vapor content of air (or other gas). The term “humidity” is a general term to quantify the amount of water vapor in the gas or atmosphere. Water vapor plays a critical role in maintaining quality and efficacy for products and technologies that are used every day as well as being essential for human existence. It is essential for manufacturers in a variety of industries to understand how accurate humidity measurements work and the roles sensor products play.

Accurate humidity measurements are vital in preventing degradation and damage to

commonly used products such as wood, metals, food, pharmaceuticals, fuels, paper products and electronic components as well as maintaining the health and productivity of employees. Accurate humidity control is important for a variety of reasons and there are issues that can occur both with too little as well as too much humidity. Today’s HVAC systems utilize a variety of equipment and techniques to monitor and control temperature and humidity as well as to monitor indoor air quality and much more.

Humidity is the amount of water vapor in the air and can be measured in both absolute and relative terms. Absolute humidity is the mass of water (MW) in a volume of air and is expressed commonly in units of g/m3. Most people are more familiar with relative humidity, which is defined as the amount of water vapor in the air relative to the maximum amount of water vapor the air can hold at a given temperature and is expressed as a simple percentage from 0 to 100%. The other term that many are familiar with thanks to the local weatherman is the term dew point and that is defined as the atmospheric temperature (varying according to pressure and humidity) below which water droplets begin to condense and dew can form.

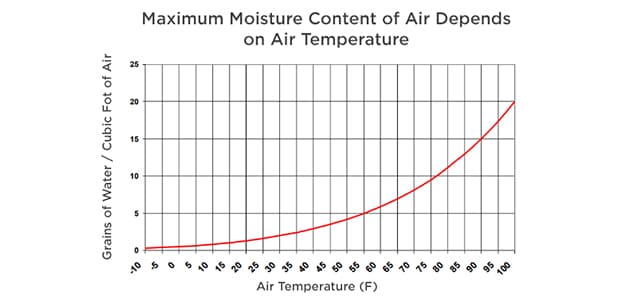

The maximum moisture content of air depends on the air temperature (and pressure) as can be seen in the graphic. The air can hold more moisture at higher temperatures which is why summer days in many locations feel “hot and sticky” and why high dewpoints make the outside air feel uncomfortable.

Most people are at least somewhat familiar with the issues from high indoor humidity levels. These issues can include poor indoor air quality, mold and mildew growth, lower productivity in industrial settings and lower quality sleep in residential settings, increased asthma and allergy symptoms, warped hardwood and furniture, strained HVAC systems and higher utility bills.

On the other hand, there are many problems associated with dry air or low indoor humidity levels and, these issues are generally less well known and understood. These issues include things like processing and handling of many materials in factories and industrial environments, electro-static discharge as well as human health and comfort. Many hygroscopic materials such as paper, leather, books, paintings and wood products require a certain level of moisture in the air to prevent cracking and curling, dry rot, gluing failure, warping and other effects. Electro-static discharge (ESD), effects everything from electronic office equipment including data centers, manufacturing facilities for electronics and any facility that handles flammable materials.

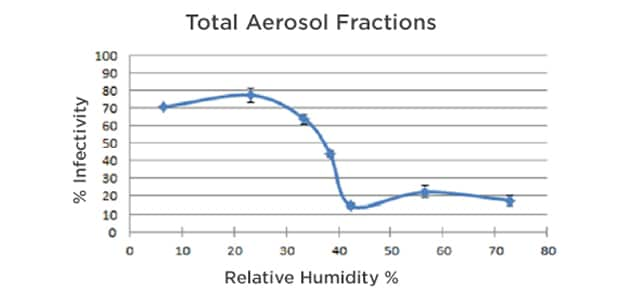

On the health side, the human body is about 65% water and the prevention of dehydration is critically important. Many human mechanisms exist to maintain the overall fluid balance in the body and health and comfort is significantly impacted by the humidity of the indoor air. Our skin, eyes and respiratory system all need proper humidity for optimal health and functionality. Research shows a link between low humidity and the likelihood of flu transmission. Studies show that higher humidity levels reduce the infectivity of the influenza virus. Our body defenses are stronger at RH levels >30%, there is less infectious flu virus in the air at higher RH levels and the likelihood of flu infectivity decreases at higher humidity levels.

So, from a health standpoint as well as comfort factors and general overall productivity standpoint, it can be shown that low and high humidity control is important for wellness, health and comfort. Optimal ranges of humidity exist not only for human comfort levels but also for bacterial spread, productivity and much more. From a workplace environment standpoint, studies concluded a wide range of improved productivity through well-being including.

• Reduced eye strain

• Reduced vocal strain

• Reduced allergy and asthma impact

• Increased employee performance

• Mental acuity

• Improved perceived comfort (“humidex”)

Humidity Sensing in HVAC Systems

HVAC systems have evolved from systems that just controlled temperature—heating or cooling or both—to systems that monitor and control not only temperature but also humidity, air quality and much more. From a humidity perspective, almost all the newer systems monitor and display humidity levels but many systems today, especially in an industrial setting can control the RH level in the building. Cooling systems, by their nature, extract humidity from the air, but by themselves are only effective when the system is calling for cooling. In order to provide the best indoor environment always and to do so efficiently and effectively, many HVAC systems now include specific components for humidification and dehumidification.

Humidity sensors play a key role not only in monitoring the humidity both indoors and outdoors but also as key components in the monitoring and control of the equipment used to modify humidity. Humidity sensors have evolved from simple resistive devices with limited range and accuracy to fully digital models that can measure both temperature and humidity over a wide range of conditions with high accuracy and little or no drift.

Humidity and Temperature Sensors

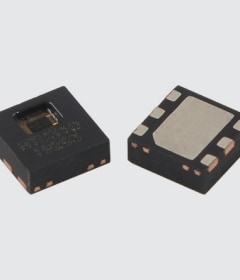

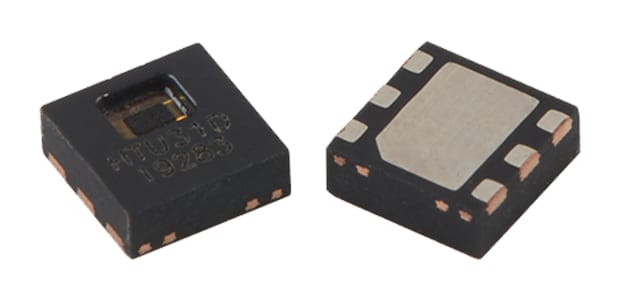

TE Connectivity has introduced a surface mountable humidity/temperature digital output combination sensor, the HTU31, in a 2.5 x 2.5 x 0.9 mm package. These individually calibrated high accuracy sensors are serialized for traceability and provide a typical accuracy of ±2% for relative humidity and ±0.2°C for temperature. They come in a compact 6-pin DFN package, provide a fast response time and have a typical power consumption of only 3.78µW. The sensors are available in both a digital I2C format with configurable addresses as well as an analog version with a 0.5-4.5V output.

Besides the HTU31, TE has a wide range of other humidity sensing products, including the HTU2x series of digital humidity-temperature sensors, the HTU35 and HTU38 humidity and temperature modules, the HM and HTM humidity-temp and humidity probes as well as the HS1101LF humidity element. Our line of humidity sensors utilize a capacitive sensing technology that can sense relative humidity over the entire 0-100% RH range, respond rapidly to changing RH levels and can recover quickly from condensation. Most include a temperature sensor that allows for direct calculation of dew point as well as the ability to monitor temperature in a room or enclosure.

Sensors, like electronics in general, continue to evolve with smaller footprints, better accuracy, fully digital outputs and lower power. Low power operation allows them to be used in a wider range of applications including battery powered ones. Smaller footprints allow the sensors to be located closer to the location of interest and also allows them to respond faster to changing conditions.

TE Connectivity offers sensor solutions to measure and regulate pressure, temperature, position, level and other parameters that are important in HVAC applications.

HVAC Pressure Sensors

TE has one of the broadest lines of pressure sensors including:

• Surface mount products used to measure barometric pressure and altitude

• Board mount pressure sensors to measure very low to medium air and gas pressures

• Modules for a range of pressures for HVAC equipment as well as diagnostic equipment

• Pressure transducers for refrigerant and other pressures in chillers, heat pumps and other rugged environments

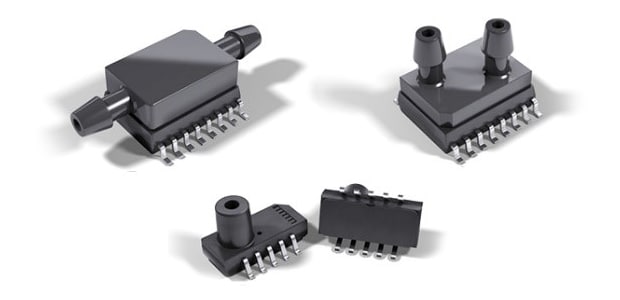

With the recent addition of Silicon Microstructures Incorporated (SMI), TE now offers very low-pressure sensors that can be used to monitor filters in forced air systems as well as monitor/regulate air flow in VAV and zoned systems. These pressure sensors are offered in a 16-pin SOIC package that is suitable for surface mounting.

HVAC Temperature Sensors

TE also offers a wide range of stand-alone temperature sensing technologies that can be used to monitor/control air temperature in industrial and residential environments as well as ruggedized temperature probes and assemblies for high moisture environments such as in control systems for heat pumps and a variety of other HVAC equipment.

Temperature technologies include NTC thermistors, platinum RTDs, thermocouples, thermopiles and digital temperature sensors. Packages range from a new fully digital TSYS03 in an ultra-compact XDFN6 package that is only 1.5mm square x 0.38mm with ±0.5°C accuracy from 0°C to 60°C to over molded NTC thermistor assemblies designed specifically for high-moisture, freeze-thaw applications typical in HVAC environments.

Humidity in Indoor Environments

Our indoor environments are becoming more comfortable and more efficient due to the growth of innovative technologies and sensors that monitor and regulate heating, ventilation and air conditioning. While temperature is the environmental parameter that people are most likely to notice first, the humidity in industrial and residential environments is critical to the long-term health and well-being of people – whether they are at work or at home. Humidity sensing and control is also important for many materials and processes in the manufacturing environment as well as for the safety of equipment and employees. The right level of humidity is critical to the overall health and wellbeing of people as well as equipment and products. The ability to sense and control humidity continues to progress and sensors play a critical role in that evolution.