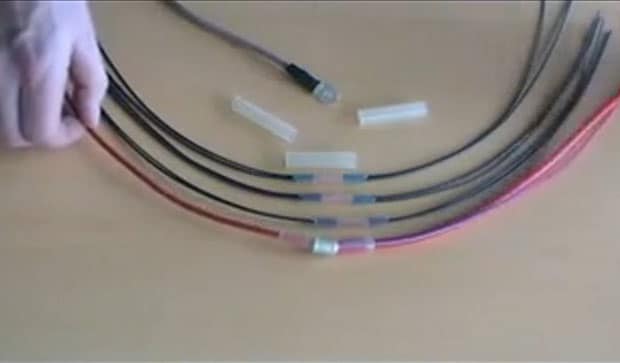

Insulate and protect with heavy duty tubing

When an application requires more robust protection, heavy duty heat-shrink tubing is the cost-effective solution for optimizing insulation and protection while providing mechanical abuse reliability and resistance to chemicals, moisture and oils.

Product Features

Shrink Ratios, Thickness, and Colors

- Shrink ratios ranging from 3:1 to 5.6:1

- Various wall thicknesses

- Choice of several color options

- Differing adhesives to bond with varous materials

- Varying levels of resistance to flame, heat, chemicals, and mechanical damage

- Recognition by various testing agencies

Heat Shrink Specifications

Shrink Ratio and Operating Temperature

| Product | Operating Temp | Min. Full Recovery | Shrink |

|---|---|---|---|

| BSTS/BSTS-FR | -55 to 90 [-67 to 194] | 121 [250] | 3:1 |

| HF | -55 to 90 [-67 to 194] | 121 [250 | 3:1 |

| HRHF/HRNF/HRSR | -55 to 90 [-67 to 194] | 121 [250 | 5.6:1 |

| RHW | -55 to 110 [-67 to 230] | 125 [257] | 3:1 |

| RMW | -55 to 110 [-67 to 230] | 125 [257] | 3:1 |

| SST/SST-FR | -55 to 90 [-67 to 194] | 121 [250] | 3:1 |

Heavy Duty Heat Shrink Tubing Portfolio

Insulation and Protection

-

BSTS/BSTS-FR Tubing

Made of a rugged polymer that resists moisture, fungus, and weathering, this tubing offers a 3:1 shrink ratio, thick-wall insulation, abrasion protection, and an FR-Flame-retardant option.

-

HF Tubing

High-flex, heavy-wall tubing developed for cable jacketing applications where cable flexibility is important. Offering 3:1 shrink ratio, it is flame-retardant.

-

HRHF/HRNF/HRSR Tubing

A high-ratio tubing that accommodates large differences between cables and cable connectors and backshells, which simplifies repair of damaged cables. Available in semirigid flame-retardant (SR), standard non-flame-retardant (NF), and high-flex flame-retardant (HF) options, its 5.6:1 shrink ratio offer toughness and durability.

-

RHW/RMW Tubing

RoHS compliant, this tubing (available in medium or heavy-wall) is designed for insulating, protecting, and a wide variety of low-voltage electrical applications. Available without adhesive, it has a 3:1 shrink ratio.

-

SST/SST-FR Tubing

This self-sealing dual wall tubing provides a simple, positive splice-sealing method that protects in extreme environmental conditions. RoHS compliant, with a 3:1 shrink ratio, it offers thick-wall insulation, strain relief. and abrasion protection. Available in a flame-retardant option.

Heat Shrink Equipment

Heaters, Ovens, and Seal Tests

-

Advanced Tooling for Efficient Heat Shrink Protection

Our equipment for heat shrink tubing seals and protects electrical splices, and provides mechanical protection for fluid management systems in harsh environments. Across a wide range of applications, we deliver optimal heating temperatures, performance and control features for greater efficiency and quality. Click to view our entire portfolio.

110°C

125°C

Minimum full recovery temperature [257°F]

110°C

Max temperature [230°F], min -55°C [-67°F]

Our heat shrink tubings are made of polyolefins, fluoropolymers, and elastomers enhanced by radiation crosslinking and heat-shrinkability. When heated during installation, our tubings shrink to conform to virtually any shape. These provide dependable insulation, mechanical protection, and strain relief, as well as aesthetic appeal. You can choose from tubings that are highly flexible or semi-rigid, designed for operation in high- or low-temperature environments. Includes halogen-free and flame-retardant products.

Heavy duty tubing products are intended for use in the most rugged environments.

- RAYCHEM Tubing Products,

- Catalog