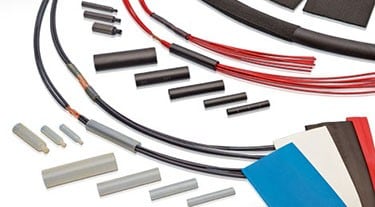

Heat shrink tubing provides electrical insulation, mechanical protection, environmental sealing, and strain relief. Available in single wall tubing and dual wall tubing, our heat shrinkable tubing is engineered for use in numerous applications, including back-end connector sealing, breakouts, and connector-to-cable transitions. It is a solid alternative to taping, molding, or potting. When heated, our RAYCHEM heat sleeves conforms to the size and shape of the substrate beneath, enabling quick and easy installation. Its high expansion ratio makes it possible to repair most damaged cable jackets without removing connectors. Available in a wide range of materials, colors, and sizes, heat shrink tubing is delivered in forms such as spools, 1.2m lengths, and cut pieces. Clear types permit inspection of covered components and offer excellent transmittance of light.

Heat Shrink Tubing Engineering and Technical Resource Hub

Welcome to the TE Heat Shrink Tubing Engineering Resource Hub — your go to destination for engineering insights, technical documentation, and application guidance on TE Connectivity’s industry-leading heat shrink tubing solutions.

Product Features: Raychem Heat Shrink Tubing

- Chemical resistant

- UV resistant

- Waterproof

- Flame retardant

- Lower applied cost

- Reduce operating time

- Strain relief for connectors and splices, providing more flexibility

- Protection against harsh environments such as abrasion, UV, and chemicals

- Sealing to keep out moisture, water, bacteria, mold, fuels, and more

- Insulation protects and minimizes heat transfer for solid thermal and electrical insulation

- Cosmetic improves organization of wires and overall assembly appearance

- Color differentiation to help identify wires for color coding

- Displacement of glass, tape or glue

Types of Heat Shrink Tubing

Uses of heat shrinkable tubing

Insulate, protect, and identify

- Shielded splice protection

- Battery terminal identification and sealing

- Mechanical protection for hoses

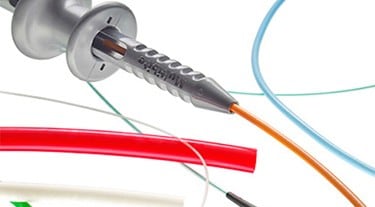

- Insulation and strain relief for fine gauge wire and fiber optic cables

- Noise reduction for pipes

- Moisture, fungus and weather resistant for outdoor applications

- Thermal insulation of substrates, pipes, hoses and cables

- Color code wiring and circuitsInsulate and protect components and wiring

- Mechanical protection for lighting components

- Bundle wires together for protection and ease of assembly