Mobile Internal Connectors for IoT

Spring finger contacts (also known as shield fingers, grounding springs, universal ground contacts, or clips) can be used in all types of small printed circuit board applications across all industries. It can be used for antenna feeds, low voltage electrical connections, or for grounding to prevent EMI noise and static caused by a speaker, motor, microphone, or any other vibration within an application. We continue to expand our spring finger contacts portfolio, offering a broad range of styles, heights, and materials to meet all customers’ needs.

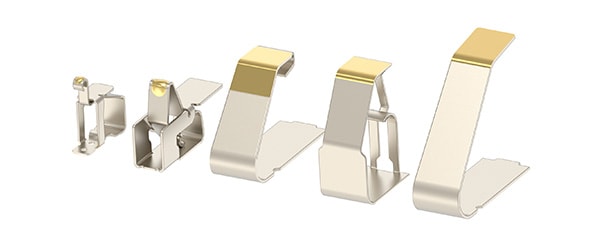

Higher Height Spring Fingers

New Product

TE Connectivity's (TE) higher height spring fingers offer an expanded portfolio of PCB universal ground contacts in higher dimensions, the portfolio now supporting a wide array of design needs from 0.8mm to 7mm, helping to protect sensitive devices from EMI noise and providing connection to ground. With a high current capacity and robust design features, TE spring fingers can support a diverse array of applications including consumer products, IoT, automotive, industrial and appliances.

- Higher height options allow designers to more easily meet distance/clearance requirements, enabling an easy and inexpensive method to connect multiple PCBs. Available in Pre-loaded Type, C Type, and Box Type, allowing for versatility in PCB layout.

- High-end performance characteristics (operating 0.5A to 2A), providing a reliable connection, helping to prevent EMI noise and static.

- Improved auto-assembly efficiency and increased ease of installation. Does not require expensive or specialized application equipment.

Ultra-Small Spring Fingers

- Save valuable PCB space with one of the smallest footprints at 1.7 mm2 in the market

- Closed-loop contact design ensures reliable connection to the PCB, better normal force and higher current capacity (1.5A)

- Robust side wall minimizes over-compression

- Special anti-lifting design can improve assembly efficiency by locking the tip of the contact within the sidewall of the spring finger, which helps prevent the contact from getting caught on an operator's glove during assembly

- Pick-and-place area supports auto-assembly processes

Spring fingers (also known as shield fingers, grounding springs, universal ground contacts or antenna clips) can be used in all types of small printed circuit board (PCB) applications across multiple industries.

Product Features

Spring Finger Contacts

- Used for grounding between a device and PCB

- Provides shielding for anything that can cause vibrations within a device, such as motors, speakers, and microphones

- Provides a cost effective solution for antenna feeds in all types of devices

- Requires limited space on a PCB

- Used as a connection for simple stacking applications between primary and secondary PCBs

- Available in heights as low as 0.4mm and up to 7mm

- Accommodates soldering and pick and place, using standard equipment

Standard Flat Contacts

Standard box and C-type connectors both have simple geometry for easy application.

Pre-loaded Spring Finger Contact

Pre-loaded spring fingers are recommended when a stable electrical contact with minimal deflection is needed. The force change is minimized over the working range of the spring finger. Pre-loaded spring fingers are available in three scalable families.

Ulta Low Profile Spring Finger Contact

Ulta low profile, Y-type spring fingers are used in applications where low effective heights are needed.

Ultra-small Spring Finger Contact

Offered in different heights and styles/form factors, ultra small spring fingers are used in a broad range of applications with space constraints across various industries.

Select Applications

Spring Finger Contacts

- IoT

- Mobile phones

- Wearable devices

- Game consoles

- Tablets

- Patient monitoring devices

- POS scanners

- Security systems

- GPS devices

Frequently Asked Questions

Spring Finger Contacts

Q: Why would I use a pre-loaded spring finger in an application?

A: A pre-loaded spring finger allows for the same amount of force with a smaller compression and provides a stable electrical contact with minimal deflection. These features are useful for applications with limited available height.

Q: Which style of spring finger is best for my application?

A: Spring fingers are typically some of the last pieces added to a board. The type used depends upon the height and space left on the board, but the decision is typically based on your design needs.

READ MORE ABOUT SPRING FINGER CONTACTS