A connector is a coupling device that joins electrical terminations to create an electrical circuit. We design and manufacture an expansive portfolio of electrical connector types that are engineered to reliably transmit data, power, and signal in the harshest environments, under the most extreme use.

What are connectors?

Connectors enable contact between wires, cables, printed circuit boards, and electronic components. Our different types of connectors including PCB connectors and wire connectors are manufactured to reduce application size and power usage while enabling increased performance.

Our portfolio includes connectors available in a wide range of positions from 0 to 4,189. Our audio and visual connectors offer enhanced board retention and EMI shielding. Our automotive connectors are built to withstand harsh conditions of highway and off-road transportation. Our computer connectors include our card edge connectors and sockets which support the current SDRAM and DDR memory generations and the new DDR2, DDR3, and DDR4 as well as FBDIMM generations. Our LUMAWISE LED holders offer a snap-in LED retention feature, which eliminates the need for soldering; it uses poke-in wire connections to provide the tool-less termination of solid, fused, and stranded wire.

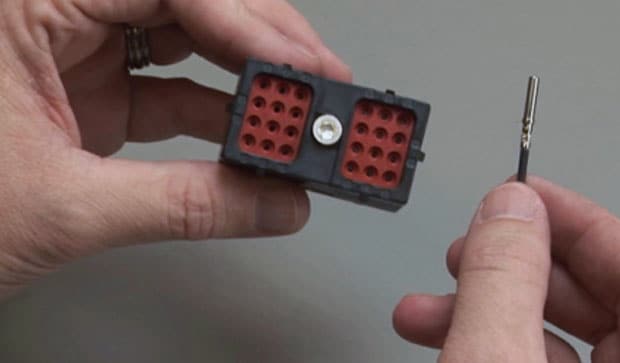

Across our portfolio, you can find different types of electrical connectors including electrical wiring connector types and cable connector types. Our connectors are engineered to optimize connectivity in critical technology systems. Our engineers are widely experienced in partnering with customers to address a variety of connectivity requirements. Our connectors portfolio includes AMP connectors and DEUTSCH connectors.

From USB connectors and RJ45 connectors to TE's DEUTSCH connectors and AMP connectors, we design and manufacture the electrical connectors and wire connectors that are making possible a connected, sustainable future. We offer many types of connectors for computers and connectors in electronics as well as wire plug connectors, electrical connector plugs, and electrical cable connectors.

- RJ45 Connectors: In computers, routers, and other communications equipment, our RJ45 connectors terminate Ethernet cables to connect to a PCB in three ways: surface mount, through hole - press fit, and through hole - solder.

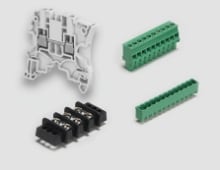

- Wire-to-Board Connectors: In home appliances, our PCB terminals fasten a wire to a board without solder, allowing quick replacement or repair. Our LCEDI connectors provide low-voltage differential signaling (LVDS) and embedded DisplayPort (eDP).

- High-Voltage Connectors: When used in electric vehicles, these connectors transmit high-voltage power from the battery to the powertrain or electric motor, while miniature connectors reliably transmit signals.

- D-Shaped Connectors: In factories and industrial environments, these connectors automate and integrate production across sophisticated systems and prevent interruptions in operation process communication.

- Lighting Connectors: In intelligent buildings and the connected home, these connectors integrate communications and security systems, HVAC controls, and power transmission.

- DEUTSCH DMC-M Series Connectors: In commercial aircraft, connectors enable critical flows for high-speed internet access, in-flight entertainment technology, and navigation, landing, and flight systems.

~121K

Connectors in our online catalog

156

Categories of TE connectors

1,200

Unique attributes for TE connectors

M8/M12 Connector System

Our M8/M12 Connector System is engineered for machine industrial automation and control applications and provides a solution for the increasing needs of sensor connections that safely and reliably ensures the communication in industrial environments. This connector system offers a compact reliable connection system with environmental protection. Our connector system includes an extensive connector range of PCB headers, cable assemblies, and I/O boxes, and provides users with an interface that supports higher bandwidth needs – meeting the requirements of up to 10Gb/s. We also offer shielded and unshielded Cat5e and Cat6A cable assembly variants. A predefined offering in length of 1, 3, 5 and 10 meters covers a vast range of customer needs on the market. For rewiring onsite, a range of field serviceable connectors are provided, allowing versatile systems to be quickly and easily established. Additional styles are available on request, including alternative mounting arrangements for panel mount connectors and double ended cable assemblies.

Industrial IoT developments ask for smaller and more reliable connectors. Latency requirements will call for higher connection reliability in environmentally severe industrial applications with vibrations. Even for industrial IP20 applications the default connector of choice is typically the RJ45, which is originally not designed for this type of use. This white paper compares Ethernet connector systems on connection reliability in industrial IP20 applications (Finger/Object protection ≥ 12.5mm, no water ingress protection). Specific tests sequences have been used to measure performance of 2 Ethernet connector systems.

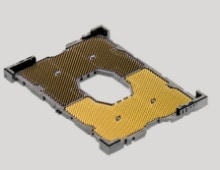

STRADA WHISPER Backplane Connectors

Our STRADA Whisper backplane connectors are designed to address the end-customer’s need for high-performing, high-bandwidth systems. This connector is designed to transfer data at blinding speeds of 56 Gbps and offers unparalleled scalability up to 112 Gbps — allowing you to achieve efficient future system upgrades without costly backplane or midplane redesigns. Our STRADA Whisper product family operates with extremely low noise, low insertion loss and little to no skew — all of which provide system architects with design flexibility and high design margin. Specific versions are available for 100-Ohm and 85-Ohm applications so you don’t have to compromise on total system impedance design. Mechanically, our STRADA Whisper connector family mirrors most high-speed backplane connectors in the market for easy implementation. It differentiates itself through folded signal pins surrounded by strong, protective C-shaped shields, which make the product family one of the most robust offerings in the market. Additionally, the connector footprint keeps crosstalk down and the overall connector design uses latest eye-of-needle (EON) technology.

AMPMODU Interconnects: Solutions for Integrated Circuits

Interconnect systems are used widely across nearly all industrial applications that require printed circuit boards (PCBs). Our portfolio of AMPMODU interconnects provides a comprehensive family of modular signal interconnects for board-to-board, wire-to-board, and wire-to-wire applications, offering centerlines from 1.00 mm (0.039”) to 3.96 mm (0.156”). Our interconnects are designed reliably and economically address a variety of packaging and interconnection requirements. Our broad range of components are engineered for a variety of high-performance applications. Our design features a small, compact footprint, which helps you save space without compromising performance quality. Our AMPMODU interconnect products are suitable for technologies and systems used in many industries.