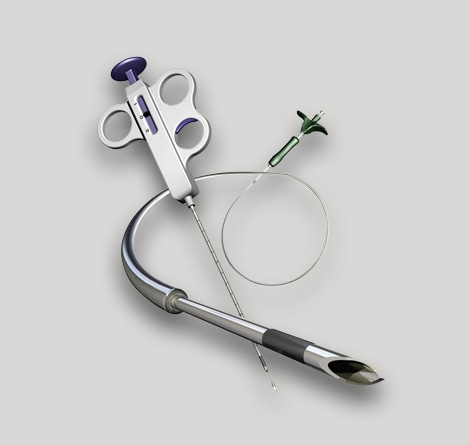

The minimally invasive medical device industry is a dynamic industry, evolving to deliver smaller and more complex devices to treat all kinds of medical issues. Precision manufacturing of laser processed components tailored for these dynamic needs is becoming more critical. In this Device Talks Tuesdays webinar, the TE experts discuss how you can harness cutting-edge laser technology, both cutting and welding, to complete your new delivery and access device or enhance your existing device.

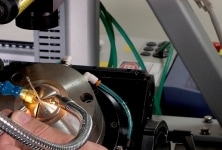

Laser Processing

TE’s laser processing capabilities are the foundation for highly precise medical devices that require clean welds without heat distortion or filler materials, need a flexible setup for various shapes and materials, and which fuse dissimilar materials with structural integrity.

Medical device manufacturing requires small-scale component parts, including difficult-to-process metals, that are machined accurately, consistently, and quickly. TE offers precision engineering through micromachining and laser processing on a wide range of components and assemblies, such as laser cut metal and laser cut tubing. Tight process controls help ensure repeatable, accurate welds of similar and dissimilar materials without thermal damage, distortions, or fillers to optimize biocompatibility for medical submissions.

Laser Processing Technologies

Medical Device Component Applications:

(select examples)

- Laser welding, laser cutting, laser marking, laser ablation, and micro engraving

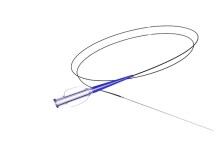

- Metals processing for surgical and machined components, metal shafts and hypotubes, wire and coil, and specialty needles

- Hermetic weld joints and helix weld coils

- Laser wire ball forming

- Laser welded torque cables, catheter tips, tube assemblies, and nitinol and filter assemblies

Materials

- Expertise across a wide range of standard materials and difficult-to process metals, including:

- Stainless steels, nickel, and cobalt chromium

- ELGILOYTM® alloy, nichrome, INVARTM® alloy, MP35NTM®, and L605

- Nitinol, titanium, platinum, and platinum alloys

- Titanium

- Polymers: Silicone, Polyurethane, PEBA, ETFE, PET, Polyimide, Polyester fabric, and many others

Laser Processing Specifications

- Laser processing of metals:

- Tolerances within 0.0005" or less

- Kerf width as small as 0.0007”

- Wall thicknesses as thin as 0.002" up to 0.030"

- Tubing diameter between 0.012" x 0.009"

- Laser processing of polymers:

- Tolerances within 0.001" or less

- Drill holes as small as 0.002" or less

- Materials as thin as 0.002" and as thick as 0.040"

Manufacturing Locations

Technical Resources

The move toward smaller medical devices has established laser cutting & welding as critical methods of medical device manufacturing. These methods are complicated but essential processes for adding functionality such as improved steering, reach or flexibility when working with materials such as metals and polymers. TE is leading a discussion about its laser processing capabilities in cutting and welding complex designs of metal components, from prototyping through to automated high-volume production.

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e