Engineered for fluid resistance and flexibility

Our high-performance heat shrinkable tubing products are designed to meet harsh environments required by most ruggedized harness designs. For more than 50 years, our general-purpose Raychem harnessing tubing are designed to withstand exposure to temperatures in excess of 200°C. The use of Raychem harnessing tubing allows simple design and cost effective custom harnesses. This product is specifically designed for aerospace and military platforms.

Product Features

Harnessing Tubing

- Heat shrinkability

- High temperature materials

- Excellent insulation property

- Few sizes covers a large range of wire diameters

- Enabling the design of harnesses for harsh environments.

- Provides insulation from damaged wires.

200C

RW-200 operating temperature

2:1

Shrink ratio for Harnessing tubing

23053

AMS-DTL 23053/1, /10, /13, and /16

Product Families

Harnessing Tubing

| Product | Operating Temperature oC | Description | |

| Elastomers | DR-25 | -75 to 150 | Diesel-resistant elastomer |

| NT | -55 to 90 | Flexible general-purpose modified elastomer | |

| NT-MIL | -70 to 121 | Flexible rugged modified elastomer | |

| NTFR | -70 to 121 | Very flexible rugged neoprene | |

| RW-200 | -40 to 200 | High-temperature fluoroelastomer | |

| RW-200-E | -55 to 200 | High-temperature fluoroelastomer | |

| SFR | -75 to 180 | Very flexible silicone - Black | |

| SRFR | -75 to 200 | Very flexible silicone rubber - Gray | |

| Fluoropolymers | RT555 | -65 to 200 | High-performance fluoropolymer |

| RT-770 | -55 to 125 | CBRN tubing | |

| RT-780 | -55 to 175 | CBRN tubing | |

| RT-790 | -55 to 200 | CBRN tubing |

See catalog above for more details

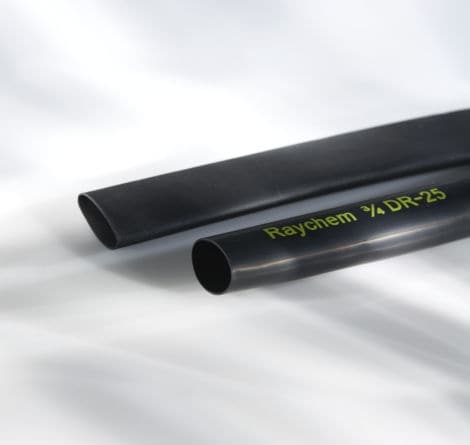

DR-25 Tubing

Product Family

Flexible, Chemical-and-Abrasion Resistant

Specially formulated for optimum high-temperature fluid resistance, and long term heat resistance. Resistant to aviation and diesel fuels, hydraulic fluids and lubricating oils.

Operating temperature range:

- -75oC to 150oC

Specifications:

- AMS-DTL-23053/16

- VG95343 Part 5 Type D

- VDE 0341/Pt 9005

- Def Stan 59-97 Issue 3 Type 6B

- BS 4G-198 Part 3 10A

| Mil Spec No. | Size | Inside Diameter Min Expanded as supplied |

Inside Diameter Max Recovered after heating |

| - | 1/8 | 3.2 (0.125) | 1.6 (0.062) |

| - | 3/16 | 4.8 (0.187) | 2.4 (0.093) |

| -001 | 1/4 | 6.4 (0.250) | 3.2 (0.125) |

| -002 | 3/8 | 9.5 (0.375) | 4.8 (0.187) |

| -003 | 1/2 | 12.7 (0.500) | 6.4 (0.250) |

| -004 | 3/4 | 19.0 (0.748) | 9.5 (0.375) |

| -005 | 1 | 25.4 (1.000) | 12.7 (0.500) |

| -006 | 1 1/2 | 38.0 (1.500) | 19.1 (0.750) |

| -007 | 2 | 51.0 (2.000) | 25.4 (1.000) |

| -008 | 3 | 76.0 (3.000) | 38.0 (1.500) |

| -009 | 4 | 101.6 (4.000) | 50.8 (2.000) |

RT555 Tubing

Product Family

Fluid-Resistant, Chemical-Resistant, Crosslinked Fluoropolymer Tubing with Extended Temperature Range

Suitable for commercial applications requiring heat resistance (electrical and hydraulic systems near aircraft or automotive engines or in fuel tanks), applications in chemically exposed environments (industrial process equipment in the pulp and paper, steel, and chemical industries), and equipment for handling many caustic or dangerous chemicals or inks.

Operating temperature range:

- -65oC to 200oC

Specifications:

- UL rating

- Listed for 185oC for 100,000-hr continuous use (File E85381)

- Listed for 200oC for 40,000-hr cumulative intermittent exposure

| Size | Inside diameter Min expanded as supplied |

Inside diameter Max recovered after heating |

| 1/8 | 3.18 (0.125) | 1.57 (0.062) |

| 3/16 | 4.75 (0.187) | 2.36 (0.093) |

| 1/4 | 6.35 (0.250) | 3.18 (0.125) |

| 3/8 | 9.53 (0.375) | 4.75 (0.187) |

| 1/2 | 12.70 (0.500) | 6.35 (0.250) |

| 5/8 | 15.88 (0.625) | 7.95 (0.313) |

| 3/4 | 19.05 (0.750) | 9.53 (0.375) |

| 1 | 25.40 (1.000) | 12.70 (0.500) |

| 1 1/4 | 31.75 (1.250) | 15.88 (0.625) |

| 1 1/2 | 38.10 (1.500) | 19.05 (0.750) |

| 2 | 50.80 (2.000) | 25.40 (1.000) |

RW-200 and RW-200-E Tubing

Product Family

Chemical-Resistant, High-Temperature

Raychem brand premium heat shrinkable tubing is fabricated from modified, crosslinked fluroelastomeric materials designed for a wide range of applications.

Operating temperature range:

- RW-200 -40oC to 200oC

- RW-200-E -55oC to 200oC

Specifications:

- RW-200

- AMS-DTL-23053/13

- RW-200-E

- VG 95343 Part 5 Type E

- Def. Stan, 59-97 Issue 3 Type 4A

- VDE 0341/Pt9005

- BS 4G-198 Part 3 12A

| Mil Spec No. | Size | Inside Diameter Min expanded as supplied |

Inside Diameter Max recovered after heating |

| -012 | 1/8 | 3.2 (0.125) | 1.6 (0.062) |

| -001 | 3/16 | 4.8 (0.187) | 2.4 (0.093) |

| -002 | 1/4 | 6.4 (0.250) | 3.2 (0.125) |

| -003 | 3/8 | 9.5 (0.375) | 4.8 (0.187) |

| -004 | 1/2 | 12.7 (0.500) | 6.4 (0.250) |

| -005 | 5/8 | 15.9 (0.625) | 7.9 (0.312) |

| -006 | 3/4 | 19.1 (0.750) | 9.5 (0.375) |

| -007 | 7/8 | 22.2 (0.875) | 11.1 (0.437) |

| -008 | 1 | 25.4 (1.000) | 12.7 (0.500) |

| -009 | 1 1/4 | 31.8 (1.250) | 15.9 (0.625) |

| -010 | 1 1/2 | 38.1 (1.500) | 19.1 (0.750) |

| -011 | 2 | 50.8 (2.000) | 25.4 (1.000) |

Select Applications

Harnessing Tubing

- Military

- Aerospace

- Ground vehicles

- Offshore

- Launch pads

- Space vehicles