Trusted Service Partner for Medical Device Innovation

From design, human factors engineering, rapid prototyping, and clinical research to volume manufacturing, we understand the product commercialization cycle and offer skill technical teams to support you bring your concepts through to launch.

Here at TE, we offer a range of products, technologies and services to enable our customers to get products to market faster and help retain market advantage for longer. We collaborate with you to identify your core competencies & focus on them; while choosing from our extensive menu of solutions, trusting us to execute and deliver your desired results. We provide effective solutions across the complete medical device product lifecycle, offering expertise for every step along the way.

Technical Resources

Connect to a higher standard of value chain resilience

Your design and development projects can be managed from one or more global centers of excellence, depending on the capabilities you required. Many locations offer dedicated R&D fabrication and testing labs, prototyping facilities, unique processing expertise and systems, and manufacturing capacity to support your project through all phases of the product development cycle.

Trusted Service Partner for Medical Device Innovation

From design, human factors engineering, rapid prototyping, and clinical research to volume manufacturing, we understand the product commercialization cycle and offer skill technical teams to support you bring your concepts through to launch.

Here at TE, we offer a range of products, technologies and services to enable our customers to get products to market faster and help retain market advantage for longer. We collaborate with you to identify your core competencies & focus on them; while choosing from our extensive menu of solutions, trusting us to execute and deliver your desired results. We provide effective solutions across the complete medical device product lifecycle, offering expertise for every step along the way.

Technical Resources

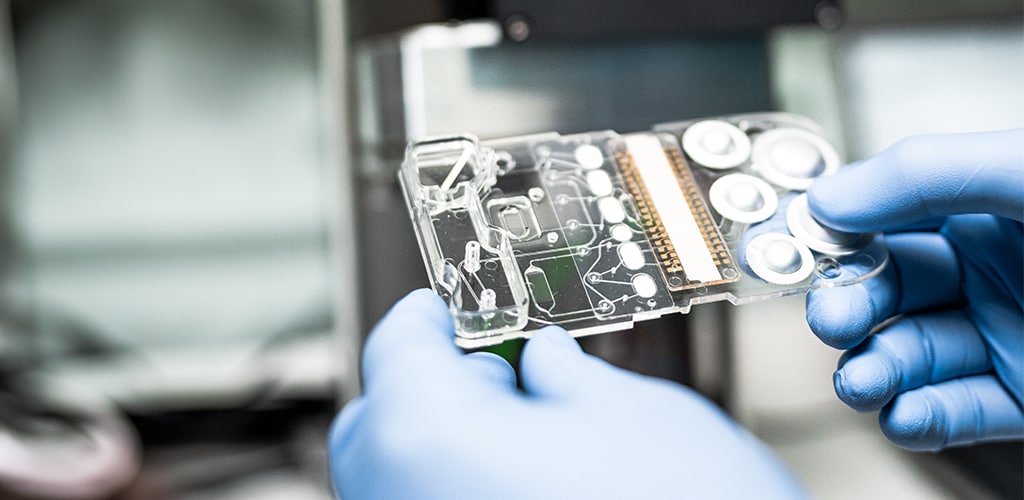

TE’s Microfluidic Molding Technology Based on Photolithography and Electroforming Process Chain Down to Micro Resolution

Connect to a higher standard of value chain resilience

Your design and development projects can be managed from one or more global centers of excellence, depending on the capabilities you required. Many locations offer dedicated R&D fabrication and testing labs, prototyping facilities, unique processing expertise and systems, and manufacturing capacity to support your project through all phases of the product development cycle.