Guidewire Assembly & Manufacturing

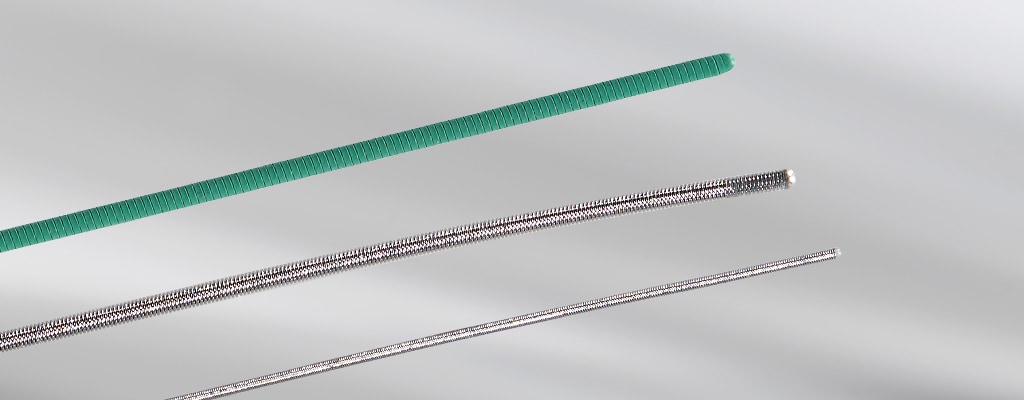

Get complete custom guidewire manufacturing services, including private label guidewires, all from one company. Our in-house guidewire assembly and manufacturing capabilities support product development through commercialization.

TE has extensive core grinding capabilities with state-of-the-art precision grinding equipment featuring computer-aided manufacturing (CAM) technology and a profilometer grind profile measurement system to ensure we meet customers’ tight tolerance precision grinding requirements. Our guidewires are used in the most challenging coronary, peripheral and neurovascular intervention applications, and our engineers are ready to help develop and design your guidewire to meet your performance requirements.

Guidewire Applications

In conjunction with our deep expertise in guidewire manufacturing, we provide innovative guidewire solutions for the following applications:

- Coronary Intervention

- Peripheral Vascular Intervention

- Gastroenterology/Renal/Urology

- Obstetrics/Gynecology

- Radiology

Guidewire Capabilities

Contact TE to discuss your guidewire construction, performance and regulatory requirements.

| Guidewire Features | Description |

|---|---|

| Guidewire OD | Ranging from 0.014” to 0.038” |

| Guidewire Length | Ranging from 40cm to 450cm |

| Core Materials | Stainless steel |

| Coil Materials | Platinum, stainless steel, tungsten |

| Coatings/Jacket | Uncoated |

| RO Marker Bands | Platinum |

- Stainless steel and nitinol core wire diameters from 0.010" to 0.038”

- Multiple tip configurations to meet guidewire performance criteria

- Laser welding processes for attaching coils and RO markers

- Packaging ranges from bulk, non-sterile to finished guidewires that are fully packaged, labeled and sterilized

- Full range of services includes: complete contract manufacturing, regulatory submission, program management, program/process development, supply chain management, packaging & sterilization

Custom Grinding

TE has expanded its core grinding capabilities with new state-of-the-art precision grinding equipment featuring CAM technology and a profilometer grind profile measurement system.

More ground core options and faster turnaround--whether you need a ground core-only job or as part of a finished guidewire project. Direct interface from CAD/CAM provides TE a stellar platform to grind single or multi-tapered grind profiles. Custom shapes and configurations are available upon request.

Materials: stainless steel, hyten stainless steel, MP35N™, and nitinol.

Sizes:

- Raw wire diameter: 0.006″

- Raw wire length: 6″ to 177″

- Ground wire diameter: 0.001″ to 0.038″

- Ground length: 0 to 20″

- Taper length: 0 to 20″

- Tip diameter: 0.001″ to 0.030″

- Barrel length: 0 to 20″

- Groove widths: 0.010″ to 1″

- Number of tapers: Up to 100

- Number of barrels: Up to 100

- Flatting: Up to 20″

Secondary Operations: Cutting, ultrasonic cleaning & coating

Custom Prototype Coils

TE’s increased coil manufacturing capacity and broad range of services allow shorter lead times and competitive pricing for coils as components or as a guidewire feature.

Engineering Support: Collaborative engineers with extensive technical experience assist you from start to finish, including design recommendations on:

- End use

- Multiple component assembly procedures

- Manufacturability

- SOLIDWORKS™ simulation, Minitab™ statistical processing

| Tolerances | Wire diameters ranging from 0.002″ to 0.016″ with coil lengths up to 450cm available |

|---|---|

| Types | Flat or round wire, left or right wind, single or multi-filar, variable pitch |

| Materials | Platinum, platinum/tungsten, stainless steel, gold-plated tungsten and more |

| Secondary Operations | Coil expansion, coatings, burr-free cuts, UV bonding, ultrasonic cleaning |