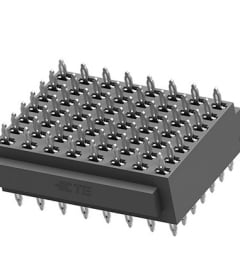

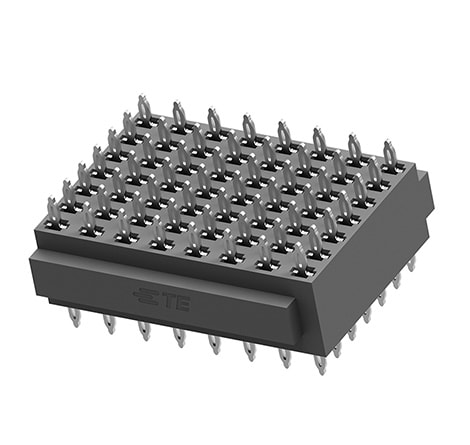

Press-Fit Stacking Connector

Have a footprint that matches VPX daughtercard layouts for low noise, gas-tight connections with low signal loss, and highly reliable performance in PCB applications. Well suited to mezzanine and parallel board-to-board, the connectors offer reliable signal integrity.

December 01, 2016

TE Connectivity (TE) (NYSE: TEL), a world leader in connectivity and sensors, recently released its press-fit stacking connector, a 56-position VPX footprint-compatible connector designed for rugged, high speed applications. Press-fit stacking connectors satisfy the need for 10Gb/s digital signals in high density packaging.

Suited for space saving in military electronics and commercial aerospace systems, TE’s press-fit stacking connectors are well suited for mezzanine and rigid flex board-to-board attachment and provide reliable signal integrity. Their footprint matches VPX daughtercard layouts for low-noise, gas tight connections. The connectors are end-to-end stackable to reach higher pin counts and use eye-of-needle compliant pins for solderless application.

“We’ve taken our time-tested compliant pin technology that is widely used in high speed VPX architecture and packaged it in a modular array to accommodate a wide range of design layouts for rugged environments,” said Mike Walmsley, product manager of global aerospace, defense & marine at TE Connectivity.

About TE

TE Connectivity is a global industrial technology leader creating a safer, sustainable, productive, and connected future. Our broad range of connectivity and sensor solutions enable the distribution of power, signal and data to advance next-generation transportation, renewable energy, automated factories, data centers, medical technology and more. With more than 85,000 employees, including 8,000 engineers, working alongside customers in approximately 140 countries, TE ensures that EVERY CONNECTION COUNTS. Learn more at www.te.com and on LinkedIn, Facebook, WeChat, Instagram and X (formerly Twitter).