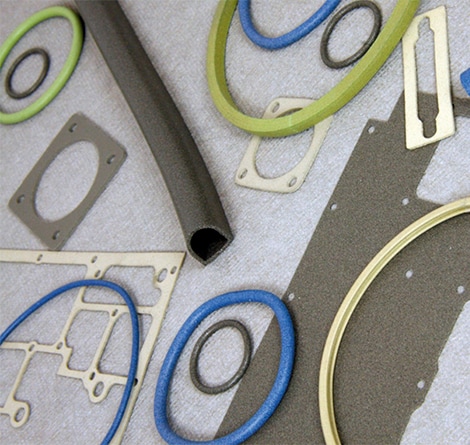

Highly conductive EMI/RFI gasket and environmental seal

EMI gaskets are made of fully cured silicone or fluorosilicone and provide environment sealing, thermal insulation, and shielding against EMI. They provide galvanic compatibility best suited for avionics, medical, military, and other applications.

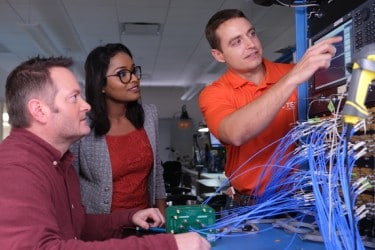

Application

- Industrial controls

- Test & measurement instruments

- Military equipment

- Avionics

- Medical electronics

- Electronic equipment enclosures

Product Variations

- Highly conductive EMI/RFI gasket and environmental seal

- Extrusions

- Flat gaskets

- O-Rings

- Sheet

Product Features

- Thickness from 0.5mm

- Wide temperature range -55˚C +200˚C

- Fluorosilicone for harsh environments: Fuel oils and solvents

- Choice of materials for galvanic compatibility

- Flammability rating: UL94 V-0

Design Considerations

- When selecting a profile it is important to give attention to the mechanical design of your product. Round and D section seals.

- Should ideally be mounted in a suitably sized channel or groove.

- If the gasket is to fit in a groove, it is important that the gasket size chosen does not overfill the groove. When using solid sections, you should ensure that the groove cross sectional area is a minimum of 5% greater than the proposed gasket cross section.

- Attention must also be paid to the closing force required to compress the gasket to the working height required.

- Self-adhesive backing can be supplied on some flat profiles and usually only partially covers an area of the extrusion.

- Available as conductive (CSAB) or non-conductive (SAB). This adhesive is an assembly aid only.