Experience Reliable Versatility with Model 105

Our Model 105 (M105) tunnel oven offers a controlled process for a wide variety of heat-shrinkable products with adaptability and operating safety.

600°C

Maximum Temperature Setting

Unlimited Tubing Length (When Running Parallel to Belt Direction)

76.2

Maximum Tubing Diameter (mm)

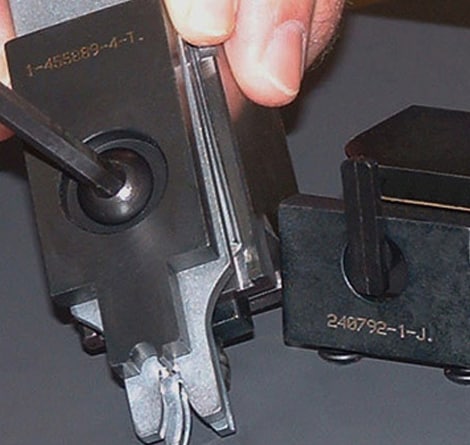

Reliable versatility. The Model 105 (M105) tunnel oven offers a controlled process for a wide variety of heat-shrinkable products. As an integrated modular unit, assemblies placed on the mesh conveyor belt are transported through the heating chamber, across a bank of cooling fans then discharged from the rear of the conveyor. It features two upper heating chamber height positions, 54 mm [2.11 in] and 98 mm [3.86 in]. The position is adjusted by removing the pivot pins and relocating them in the bearing stands.

The upper chamber is cantilevered to permit processing of assemblies that require only a portion of the assembly to pass through the heat zone, and is equipped with adjustable heat shields to maximize heating efficiency for various applications. Two stamped foil heating elements are manufactured to a strict wattage specification and consistent temperatures (600° C maximum temperature setting) are controlled by a thermocouple embedded into the upper heating element.

Features and Benefits

- Closed-loop speed and temperature control

- Continuous controlled process

- Adaptable for different applications

- CE approved for worldwide use

- Heater operation and over-temperature alarm lights

Applications

- RAYCHEM heat shrink tubing

- Single-wall heat shrink tubing

- Adhesive-lined heat shrink tubing