-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

- Track Your Order

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Track Your Order

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Overview

This product is not currently available. For more information, including distributor inventory, please contact us.

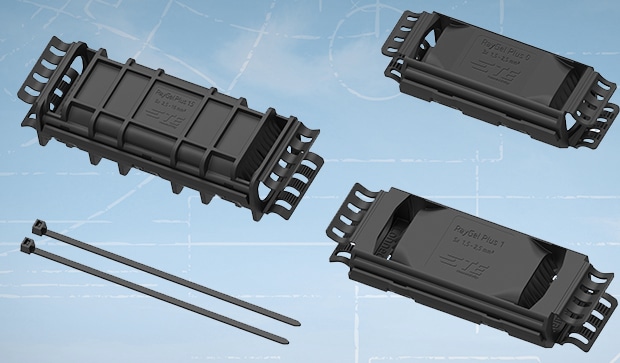

RayGel Plus Joint

Product Features

-

Joints & Splice Voltage Class(kV): ≤ 1

-

Joints & Splice Product Type: LV Gel Joint

-

Insulation: Polymeric

Available from

Overview

The RayGel Plus enclosure, with its revolutionary PowerGel sealing gel, covers and seals the joint quickly and easily, saving both time and effort, and is qualified to CENELEC EN 50393.

Our RayGel Plus joints offer protection, insulation and high-quality sealing for fast, easy and safe cable connections. The newly designed types of joints offer a full range of branching capabilities from 2x1.5 to 5x16 mm² and are suitable for underground, direct buried and overhead applications.

The RayGel Plus enclosure, with its revolutionary PowerGel, covers and seals the joint quickly and easily, saving time and effort. PowerGel is rated to 90°C continuously and is halogen-free with an unlimited shelf life. The halogen-free polypropylene enclosure is designed to only house straight and branch connections in one solution. This helps to minimize the required stock level and serves a wide range of applications.

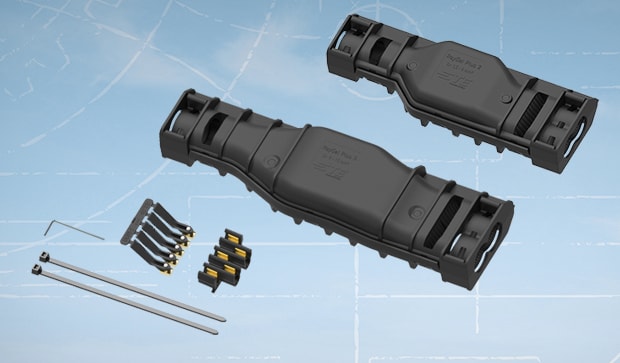

Our RayGel Plus joints can be snap-closed by hand due to its flexible wave-like gel barriers. A strain relief is integrated within the enclosure and quickly installed with two cable ties. With the unique universal connector block, installation is very straightforward, as the block snaps into the bottom side of the enclosure. A supplementary tool helps to insert the sliding nuts and holds them in place until the connection is finalized.

Key Features

- Quick, easy, and clean installation, latchable connector blocks.

- Suitable for outdoor and direct-buried applications (IP 68).

- Full branch capabilities without cutting of main cables.

- Optimized joint design with integrated strain relief.

- Qualified to international joint standard CENELEC EN 50393.

- Halogen-free and UV-resistant.

- High shelf life.

- Environment-friendly and not subject to labeling requirements.

With the RayGel Plus joints filled with PowerGel - for single and multi-core polymeric cables 0.6/1 kV - it is easier than ever to install cable connections for underground, direct buried, and overhead applications. Watch the RayGel Plus joints installation video to learn more.

With the RayGel Plus joints filled with PowerGel - for single and multi-core polymeric cables 0.6/1 kV - it is easier than ever to install cable connections for underground, direct buried, and overhead applications. Watch the RayGel Plus joints installation video to learn more.

FAQ

Frequently Asked Questions

Question. What is RayGel Plus?

Answer. RayGel Plus joints are designed to protect, insulate, and seal joint connections of 0.6/1 kV or less. RayGel Plus enclosures are made of halogen-free polypropylene and filled with PowerGel. They are for underground, direct buried, or overhead applications (see also brochure EPP-1917 – RayGel Plus Joints).

Question. What can RayGel Plus joints do for me?

Answer. Provide an easy-to-install cold-applied LV inline & branch joint for cross sections up to 50 mm² on single-core polymeric cables and up to 16 mm2 on multi-core polymeric cables with circular aluminum or copper conductors, stranded or solid.

Question. Which connectors can be used?

Answer. RayGel Plus 0 and 1 joints can be used with all types that dimensionally fit into the enclosure, such as terminal strips push-wire connectors, mechanical blocks, and C-crimp connectors. RayGel Plus 2 and 3 have universal connector blocks designed to snap into the bottom side of the enclosure. A supplementary tool helps to insert the sliding nuts and hold them in place until the connection is finalized. These connectors have full branching capabilities without cutting the main cables.

Question. What types of cables can be used?

Answer. RayGel Plus joints are designed for single and multi-core non-armored cables with circular copper or aluminum conductors, both stranded and solid. All joints were tested with cables having PVC insulation.

Question. What is PowerGel sealant?

Answer. TE Connectivity’s PowerGel sealant is used in many other products to provide sealing and insulation for underground, direct-buried, submersed, and overhead applications. Gel combines the advantages of both, solid and liquid insulating materials. It has a shape memory like a soft rubber, but can easily conform to intricate shapes and “wet” the surface like a liquid to provide a seal. PowerGel was developed for power cables and to withstand temperatures of -40°C to over 90°C.

Question. Are RayGel Plus joints UV-resistant and halogen-free?

Answer. Yes, the enclosure and PowerGel are UV-resistant and halogen-free.

Question. Will the PowerGel harden or change after installation?

Answer. No. The PowerGel sealant will maintain its physical characteristics. It will not harden or become brittle.

Question. Will the materials hold up in harsh environments?

Answer. Yes, RayGel Plus enclosures and PowerGel sealant are designed to withstand the harsh environments of industrial plants or other high-corrosion areas. The enclosures are mechanically robust.

Question. Is RayGel Plus flame retardant?

Answer. The cover and gel are not flame retardant. However, both materials are considered to be self-extinguishing.

Question. Sometimes I see a few bubbles in the gel. Is this a problem?

Answer. No. Sometimes during the manufacturing process, a few air bubbles are trapped in the gel. These bubbles will not cause any performance issues.

Question. Is there a shelf life and how long will it last after installation? (Lifetime of product).

Answer. RayGel Plus joints do not have a shelf life. They are designed for a >30-year lifetime. The design goal was to be as good as or even better than the cable itself.

Question. Is RayGel Plus re-usable? Can you remove the enclosure and/or connector and re-install them?

Answer. No, the kit is not considered to be reusable. The gel may be left on the connector or changed in a way that will prevent a good seal. But it is considered as re-enterable. The enclosure and the PowerGel can be removed from the joint easily.

Question. Which Safety Data Sheets are available?

Answer. No MSDS sheet is required or available for the RayGel Plus joints. PowerGel is supplied in a cured form. Therefore, the joint is considered an “article” which does not require an MSDS. Silicone gel is considered a non-hazardous mixture. Silicone gel is not considered to be a skin irritant and is not considered to be toxic by skin absorption.

Features

Please review product documents or contact us for the latest agency approval information.

Product Type Features

-

Material System Silicone

-

Adhesive Coating Silicone Gel

-

Joints & Splice Technology Cold Applied, Cold Shrink

-

Joints & Splice Product Type LV Gel Joint

-

Insulation Polymeric

-

Mechanical Connectors Included No, Yes

-

Closing Method Snap, Snap to Close

-

Product Family RayGel

-

Cable Seal Gel

-

Filler PowerGel

-

Shelf Life Unlimited

-

Strain Relief Yes

-

Component Design PowerGel Sealing Gel

-

Tap Geometry Parallel

-

Connector Type Connector Block

-

Case Seal Gel

Configuration Features

-

Number of Main Wires (Max) 3, 4, 5

-

Number of Branch Wires (Max) 3, 5

Electrical Characteristics

-

Joints & Splice Voltage Class (kV) ≤ 1

Body Features

-

Color Black

-

Partition Orientation Horizontal/Vertical

Mechanical Attachment

-

Mechanical Reinforcement Cable Ties

Dimensions

-

Cable Connection Mechanical Connector

-

Conductor Range (Main) (mm²) 1.5 – 6

-

Cross-Section Range (mm²) 1.5 – 2.5, 1.5 – 6, 2.5 – 16, 6 – 16

-

Cable Cross-Section (Max) (Main) (mm²) 2.5, 6, 16

-

Cable Cross-Section (Min) (Main) (mm²) 1.5, 2.5, 6

-

Cable Diameter (Max) (Main) (mm) 16, 18, 22, 25, 26

-

Branch Cable Cross-Section (Min) (mm²) 1.5, 2.5

-

Branch Cable Diameter (Max) (mm) 12, 16, 21, 25

-

Branch Cable Cross-Section (Max) (mm²) 1.5, 16, 6

-

Cable Diameter (Min) (Main) (mm) 10, 14, 8

-

Branch Cable Diameter (Min) (mm) 14, 8, 9

Usage Conditions

-

Operating Temperature Range (°C) -20 – 55

-

Environmental Resistance Moisture, Weathering, Rain, Salt Water, Contaminated Water …

-

Chemical Resistance Water & Humic Acids

Operation/Application

-

Silicone-Free No

-

UV-Stabilized Yes

-

Halogen Free Yes

-

Low Smoke Emission No

-

Emission Free Label-Free Acc (REACH & CLP) Yes

-

Marine-Offshore-Shipbuilding Certified No

-

Solvent-Free Yes

-

Free of Lead, Cadmium, Heavy Metals Yes

-

Non-Toxic & Non-Corrosive Emission Isocyanate-Free Yes

-

Emission Free Yes

Industry Standards

-

Standards EN 50393

-

CSA Certified No

-

UL Rating No

-

Design Specification CENELEC 50393

Product Availability

-

Joints & Splice Product Availability AMERICAS, ANZPAC, ASIA, China, EMEA, Worldwide

-

Minimum Order Quantity 1

Packaging Features

-

Packaging Quantity 1

-

Standard Pack 1

-

Minimum Packaging Unit 1

-

Packaging Method Cardbox

Other

-

Product Use Outdoor, Overhead & Direct Buried, PowerGel-filled box for LV underground & overhead splices.

-

Other Colors Available No

Reference Number

-

TE Internal Number CAT-RAYGEL-PLUS

Related Materials

Datasheets & Catalog Pages

- RAYGEL PLUS JOINTS FILLED WITH POWERGEL FOR SINGLE AND MULTI-CORE POLYMERIC CABLES pdf English

- RayGel Plus Brochure pdf French

- RayGel Plus Brochure pdf English

- RayGel Plus Brochure pdf German

- RAYGEL PLUS - CABLE JOINTS FILLED WITH POWERGEL FOR SINGLE AND MULTI-CORE POLYMERIC CABLES 0.6/1 KV pdf English

Are you sure you want to close chat?

Chat

To begin your chat with TE please enter your details