Application

E-DRIVE SYSTEMS

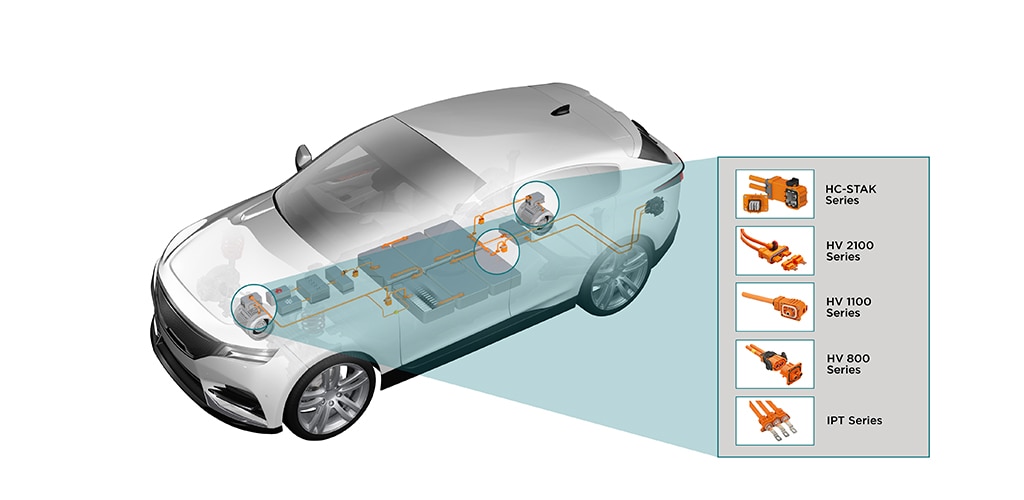

High-voltage, high-current interconnectivity solutions for an EV’s drivetrain

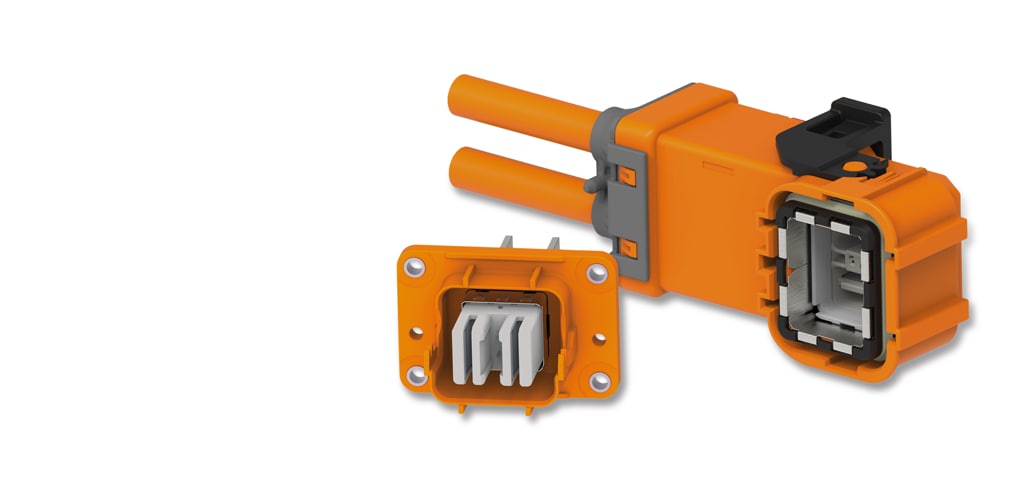

Electric vehicle connection systems need to be able to carry very high current levels, especially during high-powered charging sessions or during periods of peak acceleration. But cars inherently have limited physical space under the hood, so these electrical connections also need to be optimized for compactness, weight, and geometric flexibility, as well as cost.

TE Connectivity’s e-drive interconnection systems are specifically designed to provide a safe, reliable high-voltage/high-current connection between an EV’s traction battery, power distribution unit, invertor, and the e-motor. Our broad portfolio of connectors, headers and terminals covers an EV’s complete electrical connectivity needs. Our Class 4/5/6 products provide the ability to transfer power at high current levels for performance-demanding electric drivetrain applications.

Product families in the Class 4/5/6 category include the versatile HC-STAK interconnection system, the HV 2100 series, the HV 1100 series, the HV 800 series interconnection systems, and the IPT system. Combined, these solutions offer thousands of configuration options and an array of device and wire harness applications.

Key Benefits

- Rated for up to 1000 VDC and up to 407 A at 85° C

- Compact: Package-maximized for size, bulk, weight, flexibility, and cost

- Scalable: Can accept a variety of conductor sizes and materials

- Safe: Touch-safe finger protection with Connector Position Assurance (CPA)

- Easy to assemble: Tool-activated and finger-activated latching

- Flame-, vibration-, and moisture-resistant

- Automation-capable options available for improved manufacturing efficiency

Explore More

Application

E-DRIVE SYSTEMS

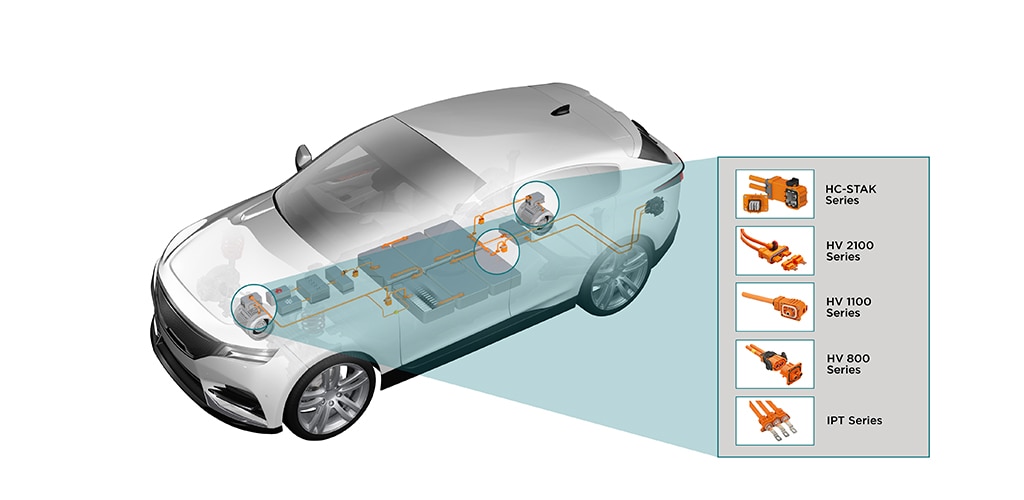

High-voltage, high-current interconnectivity solutions for an EV’s drivetrain

Electric vehicle connection systems need to be able to carry very high current levels, especially during high-powered charging sessions or during periods of peak acceleration. But cars inherently have limited physical space under the hood, so these electrical connections also need to be optimized for compactness, weight, and geometric flexibility, as well as cost.

TE Connectivity’s e-drive interconnection systems are specifically designed to provide a safe, reliable high-voltage/high-current connection between an EV’s traction battery, power distribution unit, invertor, and the e-motor. Our broad portfolio of connectors, headers and terminals covers an EV’s complete electrical connectivity needs. Our Class 4/5/6 products provide the ability to transfer power at high current levels for performance-demanding electric drivetrain applications.

Product families in the Class 4/5/6 category include the versatile HC-STAK interconnection system, the HV 2100 series, the HV 1100 series, the HV 800 series interconnection systems, and the IPT system. Combined, these solutions offer thousands of configuration options and an array of device and wire harness applications.

Key Benefits

- Rated for up to 1000 VDC and up to 407 A at 85° C

- Compact: Package-maximized for size, bulk, weight, flexibility, and cost

- Scalable: Can accept a variety of conductor sizes and materials

- Safe: Touch-safe finger protection with Connector Position Assurance (CPA)

- Easy to assemble: Tool-activated and finger-activated latching

- Flame-, vibration-, and moisture-resistant

- Automation-capable options available for improved manufacturing efficiency