Empowering Engineers for Tech Innovation

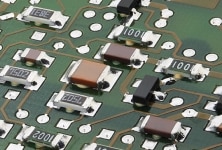

TE Connectivity helps engineers design and build the technologies transforming how people live, work, and connect As a go-to engineering partner for innovation leaders and technology entrepreneurs, we work on solving tomorrow's toughest technology challenges today. Our global team of regionally located experts – which includes electrical and mechanical engineers – develops and manufactures connectivity solutions enabling technological innovation for a safer, sustainable, productive, and connected world. Our broad portfolio of electrical parts and electronic components including different types of sensors are optimally engineered to reliably connect, protect, and optimize the flow of data, power, and signal – in electric vehicles and aircraft, in digital factories and smart homes, and in life-saving medical devices, efficient utility networks, and the global communications infrastructure, from IOT devices to AI systems. As a trusted electronics manufacturer with 80 years of experience in developing innovative and reliable solutions for industry applications and technological architectures, we work closely with customers to address their reliability, safety, and sustainability challenges.

With the rise of generative artificial intelligence (AI), data centers have become an increasingly critical part of the world’s technological infrastructure — and a growing consumer of electricity. Even small-scale improvements involving the types of cables, connectors, and heat dissipation equipment used can have a huge impact on the amount of energy data connectivity systems use, helping increase data center sustainability.

Move data more efficiently to support AI technologiesMeet TE Experts at Events Worldwide

Find Us at Shows Near YouQuick access to top-searched products

Featured Tech Explainers

Our Approach to Business Innovation & Inclusion

Performance Sustainability

Our commitment to sustainability includes helping our partners innovate sustainably.

Supplier Empowerment

Learn about our program for strategically empowering diversity-owned suppliers.

Industrial Technology Index

Our global survey reveals innovation challenges and opportunities for success.

TE in the News

Stories from across the web

- Next2OEM project: "TE Connectivity advances OEM-ready automation by designing wiring harness components for end-to-end robotic assembly." Link directs to automation-mag.com

- "TE Connectivity’s ECONIDUR Plating is a breakthrough connector contact solution that blends high performance with sustainability." Link directs to DigiKey.com

- "VITA 100 uses TE Connectivity’s MULTIGIG HD 2 connector that doubles the pin density of current VPX connectors, allowing for more connections in the same physical space." Link directs to ElectronicDesign.com

- "TE Connectivity’s OSFP-XD LPO Transceiver for PCIe Gen 6 Connectivity Over Optics, demonstrated at OFC 2025, is an innovative module is suitable for PCIe Gen 6 (64 GT/s per lane), delivering a total bandwidth of up to 256 GB/s in a 16-lane configuration, while maintaining a low power consumption of 8.5W." Link directs to ConnectorSupplier.com

- "TE Connectivity launches ultra-low-profile PCIe Gen 7 connectors to support the data speeds and electrical performance required by next-generation data centres and AI applications." Link directs to NewElectronics.co.uk

- Webinar – Engineering Industrial Automation in the Industry 4.0 Era, with insight from TE engineers on the solutions for powering smart factory technologies. In partnership with Digikey. Link directs to on24.com

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e

e