High Reliability Automotive Connectors, Housings, & Contacts

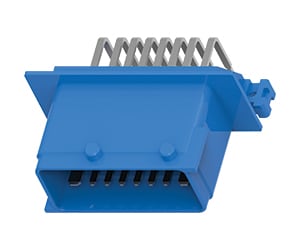

TE Connectivity's (TE) AMP MCP interconnection system is designed for electronic and electrical power applications in passenger cars and commercial vehicles as well as harsh environment off highway vehicle applications.

High Reliability Automotive Connectors, Housings and Contacts

TE Connectivity's (TE) AMP MCP interconnection system is designed for electronic and electrical power applications in passenger cars and commercial vehicles as well as harsh environment off highway vehicle applications.

2.8=6

Low terminal mating force (6 Newtons)

48V

Base material with very high current carrying capacity

.2–16

Large range of wire sizes from 0.2mm2 - 16.00mm2

AMP MCP Contact System

The AMP MCP connector contacts are two-piece receptacle/tab designs with separate electrical and mechanical properties. This design supports high current carrying capacity, reliability and high vibration levels. The contacts suit customer needs for power connections in sealed and unsealed applications, wire-to-wire and wire-to-board applications, and high voltage or higher vibration applications and are available with a large connector and header portfolio. For a fast and economic termination process, TE Application Tooling offers a vast portfolio of application equipment.

Features

- High vibrational load with multiple contact points

- Large range of wire sizes (from 0.2 mm2 for AMP MCP 1.5K terminals up to 16.0 mm2 for AMP MCP 9.5 terminals)

- Protected contact spring from closed box design and overstress protection of the contact spring

- High current capability with CuNiSi base material

- Sealed versions utilize a single wire seal applied to the wire prior to crimping

- -40°C to 150°C contact plating temperature range

- LITEFORCE contact design for high vibration and less insertion force

- Contact-to-contact mating ranges 10 to 100 cycles

- Secondary locking possibilities from four sides with protected locking lances

Types of MCP Contacts

Housings & Connectors

The AMP MCP connector system offers receptacle and tab housings with capability for waterproofing and resistance to conditions of extreme vibration. The system is designed for electronic and electrical applications in motor vehicles, where vibrations and mechanical stress, in the long term, can affect the quality of the contact system. Available in sealed and unsealed versions, including hybrid versions compatible with other TE Connectivity connector systems such as MCON or MQS, for signal and power contacts.

Features

- CPA (Connector Position Assurance) capability for reliability and security

- High vibration level supported

- Small connectors with integral latches

- Large connectors with lever locks

- Intergrated secondary locking device delivered in pre-locked position

- Wire-to-wire, wire-to-board and wire-to-device sealed and unsealed connectors

- Design incorporates mechanical polarization

- Available in multiple position combinations for 1 up to 100

- Hybrid versions compatible with MCON and MQS for signal and power contacts

- Color keying available to prevent improper mating

TYPES OF HOUSINGS AND CONNECTORS

AMP MCP HEADERS

AMP MCP automotive-grade PCB headers support low-to-medium power and are offered in multiple configurations and designed for electrical and electrical power applications in passenger cars and commercial vehicles as well as harsh environment off-highway vehicle applications. Our innovative related technologies such as Press-Fit, including innovative insertion zone technology and ultra-low risk plating together with reliable sealing machines, enables efficient solder-free manufacturing efficiency. Our headers are also pre-verified with our terminal technologies, providing end-to-end solutions that help eliminate compatibility issues and risk of manufacturing disruption.

Features

- Support almost all automotive harsh environment applications

- Complementary press-fit and ultra-low whisker risk plating technologies and pre-verified terminals

- Original automotive-grade design and manufacturing

- Automotive-grade quality assurance and global standards/compliance

- Global design and manufacturing

TYPES OF HEADERS

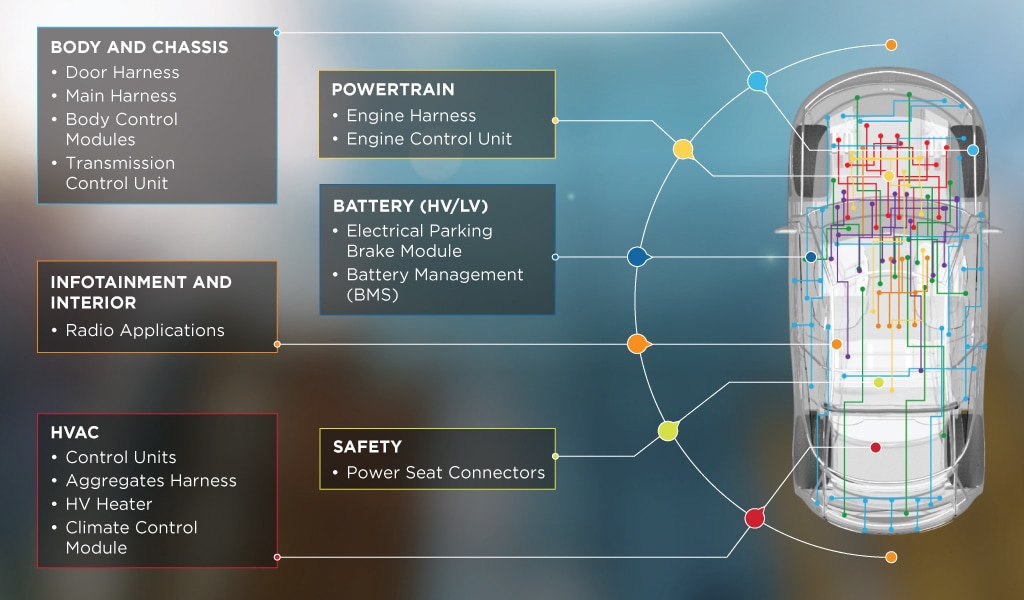

AMP MCP Applications