Trend Insight

48V Electrical and Electronic Systems

As OEMs increase electronics, power demands grow, leading to a shift to 48V systems. Providing the same power as 12V with less current, 48V enables lighter wiring, boosting efficiency, reducing weight, and enhancing sustainability by minimizing materials and power loss.

Connectivity Solutions for 48V Architectures

As automotive low-voltage E/E architecture transitions toward the 48V standard, TE Connectivity is leading the way with a broad portfolio of advanced, high-performance solutions designed to meet the evolving demands of modern vehicles. Our robust and flexible 48V offerings are engineered to enhance and maximize efficiency and scalability, reduce weight and cost, support automation, and improve overall system performance—empowering the next generation of sustainable and intelligent vehicle architectures. As a global leader in connectivity and a key driver of the new 48V LVCS interface standardization, TE delivers the technology and expertise needed to ensure the highest levels of safety, reliability, and compliance with ISO and other critical certifications. Our solutions are specifically developed to meet stringent creepage and clearance requirements, providing durable, future-ready technology built for the challenges of tomorrow's automotive systems.

48 Volt Connector Requirements

TE Connectivity’s 48V automotive connectors are designed to meet strict requirements for creepage and clearance, ensuring safe, arc-free performance in high-voltage environments. With robust locking mechanisms and compliance with key automotive standards, these connectors offer reliable operation under harsh conditions. Our evaluation process considers pollution level, material group, voltage rating, and altitude to calculate minimum spacing needs. Connectors using single wire seals with terminal sizes not smaller than 1.2mm (some 0.64mm) typically meet 48V standards due to the inherent spacing in the seal design. Additionally, TE has developed an internal creepage and clearance calculator to support this process. If a connector does not meet 48V criteria, selective cavity population can be used to artificially increase terminal spacing and achieve compliance.

The Creepage and Clearance calculator example

The Creepage and Clearance calculator example that is provided here, illustrates the general parameters outlined in the international standard DIN EN 60664-1 guidelines for required distances to ensure safe electrical separation between different circuits. For guidance tailored to your specific application, please consult a TE representative to ensure all requirements are properly addressed.

| INPUTS | |

| Application Voltage: |

60V |

| Pollution Degree (Sealed ): |

2 |

| Pollution Degree (Unsealed ): | 3 |

| Altitude: |

5000 m |

| Overvoltage Category (I-IV): |

I |

| Reinforced Insulation Factor (Clearance): |

1.0 X |

| Reinforced Insulation Factor (Creepage): |

1.0X |

| CLEARANCE | |

| Impulse Voltage: |

500V |

| Required Minimum Clearance (@sea level): |

0.20 mm |

| Altitude Correction Factor: |

1.48 X |

| Required Minimum Clearance (@5000m): |

0.30 mm |

| CREEPAGE |

|

| Material Group: |

IIIa |

| Groove Width: |

1.00 mm |

| Required Minimum Creepage: |

1.24 mm |

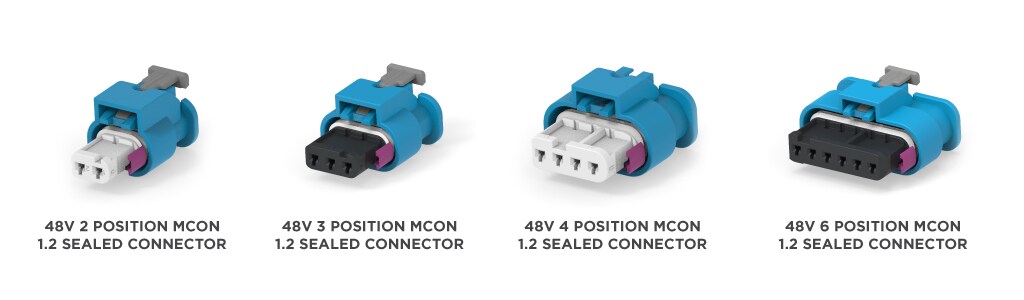

48V Connectors

View 48 Volt Ready Connector Portfolio

TE in news

48V Resources

48V Applications

48V Applications

- Active Suspension

- Roll Stabilization

- Vaccum Pump

- Steering-by-Wire

- Anti-Lock Braking System

- Powered Steering System

- Integrated Power Brake

- iBooster Brake System

DRIVETRAIN

- Electric Supercharger

- Water Pump

- Starter

- Engine Cooling Fan

- Fuel Pump

- Starter Generator

- DC/DC Converter

INFOTAINMENT

- Audio Amplifier

BODY CONTROL

- Seat Heater

- Active Body Control

- AC Compressor

- Electric Heating

- Exterior Light

- Windscreen Heater

- Auxiliary Heater

Related Products and Technologies

e

e

e

e

e

e

e

e

e

e