The move toward smaller medical devices has established laser cutting & welding as critical methods of medical device manufacturing. These methods are complicated but essential processes for adding functionality such as improved steering, reach or flexibility when working with materials such as metals and polymers. In this webinar, TE discusses its laser processing capabilities in cutting and welding complex designs of metal components, from prototyping to automated high-volume production.

Fractional Metal Tubing

Fractional tubing is used in medical device applications that require corrosion resistance and good strength. It is normally available in commercial ratings such as ASTM-A-269, ROHS, Mil-T-8504 and ASM-5570.

Our fractional tubing offerings start at 1/32″ OD and are generally stocked in 304 and 316 stainless steels but are also available in many other metals and alloys in a variety of specifications. It is typically stocked in the annealed temper condition and is available as welded tubing (welded and drawn) or seamless tubing. We also have in-house capabilities to produce custom sizes and hold the chemical composition of the starting specification to reduce lead times.

Materials & Specifications

Standard Materials

| Grade | Material |

|---|---|

| 304 |

Stainless Steel Tubing |

| 304L |

Stainless Steel Tubing |

| 316 |

Stainless Steel Tubing |

| Other Grades | Call for Availability of Other Stainless Steel Tubing Alloys |

Fractional Tubing Tolerances

| F1-Standard Tol | F2-Close Tol | |||

|---|---|---|---|---|

| Tube Size OD (Inches) | Tolerance OD (Inches) | Tolerance Wall (%) | Tolerance OD (Inches) | Tolerance Wall (%) |

| Less than 3/32 (.0938”) |

±.005” |

±15% | +.002/-.000 | ±10% |

| 3/32 to < 3/16 (.1875”) |

±.005” |

±15% | +.003/-.000 | ±10% |

| 3/16 to < 1/2 (.500”) | ±.005” | ±15% | +.004/-.000 | ±10% |

| 1/2 to < 1-1/2 (1.500”) |

±.005” | ±10% | +.005/-.000 | ±10% |

| 1-1/2 to < 3-1/2 |

±.010” | ±10% | n/a | n/a |

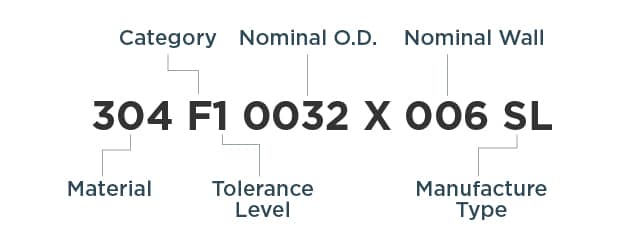

Ordering Information

Complete Offerings and Specifications

Please call +1 800-255-8823 (+1 800-ALL-TUBE) or request a quote for custom orders, products not available in our online store, custom lengths and large quantities.

Technical Resources

If you could help increase physician confidence, reduce patient risk and maximize revenue, would you choose to? In this webinar, TE explores various novel alloy options for interventional cardiology, neurointerventional and endoscopic device solutions. TE details the materials that can optimize catheter performance, improved kink and resistance, and easier device navigation, whilst giving you the technical benefits and challenges of each alloy.