Trend Insight

Advancing Performance

Advanced sensors are enabling motorsport engineers to generate data on vehicle and driver performance. The result is a new level of visibility, which is informing the technology and the strategy, and proving the crucial difference between winning and second place. By: Paul Webb, TE Connectivity (TE)'s Sales and Marketing Manager, Autosport

If you watch any racing on TV, or better still at a track, you will see plenty of people in the team garages with headsets on staring at a screen. If you catch a glimpse of that screen, it seems to be covered in lines jumping up and down a graph. This is obviously very interesting to them and to anyone who wants to make their race car go faster, as here – in all its glory – is shown what exactly is happening in the race car.

Although this seems to be a major side of racing now, this was not always the case. In fact, there were not motorsport-specific systems or hardware until the late 1980s. Before then, chief mechanics would work closely with the driver, and using their experience, work out ways of making the car behave more to their liking. Simple recording devices were first seen in testing in the 1970s, but the units that recorded the data were pretty large and added extra weight that could be better used elsewhere, so did not feature in actual races until much later. In addition to size and weight concerns, drivers were often a bit suspicious about having all their actions recorded electronically. Who would admit to not taking a corner at full throttle if asked? However, after they understand that the data can help make their car quicker, most drivers cannot get enough of the squiggly lines on the screen in front of them.

Turning Race Cars into Data Generators

In the late 1980s, the key to getting more data was the availability of more computing power. Race cars already had basic electronics for the fuel injection systems, but very little that actually monitored what the driver inputs were, and as a result, what the race car did in response. Even if they could monitor a sensor, they could only capture this information on a floppy disk. At this time, motorsport-specific data logging was appearing in the US and Europe; and the data captured from a lap was recorded on a logger, for later download.

One of the first things they discovered was what a violent place a racing car could be. You do not want a race car with much suspension movement (it upsets the weight transfer during cornering) and also any aerodynamic disruption will also make the race car unpredictable and make an otherwise normal driver pretty grumpy! Meaning, the race car must be very stiff, especially because driving over curbs creates huge energy which is painful to the driver and the race car. In Formula 1 races, which pioneered the use of more and more data, teams originally used military-grade products just so the electronics could survive the race. As Peter Wright, technical director for a Formula 1 Team, once observed1, "the objective in engineering a Formula 1 car is to ensure that the vehicle can maintain maximum acceleration, at all time as it travels around the defined path of the course."

What Factors Influence Performance?

Identifying the Right Elements

- Tires: In track racing, it is critical to keep the four contact patches working as efficiently as possible for the length of time used on the race car.

- Aerodynamics: A key to success is ensuring that the work in the windtunnel (or with Computational Fluid Dynamics CFD) replicates conditions as closely as possible to those experienced on the racetrack.

- Suspension: When the aerodynamics are less effective (at slow speeds), the mechanical grip of the race car must be optimized.

- Driver input: Different driving styles require different car setups, so understanding the way a driver naturally wants to attack a corner is essential for a fast lap.

...the objective in engineering a Formula 1 car is to ensure that the vehicle can maintain maximum acceleration, at all time as it travels around the defined path of the course.

Turning Data into Insight

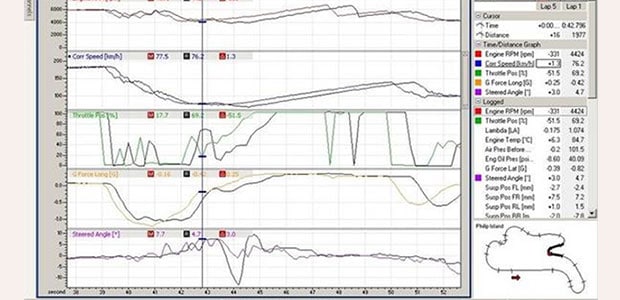

Data from the race car also helps the race engineers understand the health of the car too, particularly in relation to temperatures and pressures. Just like on a road car, these must match the zone which the designers had in mind. So, we have established data is important in modern racing. But how is it used to make a race car go faster? The image below shows a typical logging screen from manufacturer MoTeC*, showing changes in the car’s data as it progresses round a lap. Modern race cars record hundreds of channels of data, so the engineers on the pit wall only focus on a few in real-time; they will review all the data gathered after the race to see what they can learn from the event.

This graphic shows some of the information that helps data engineers gauge the performance of race cars.

This is a topic that can fill many books. So here, we will look at a few simple examples and show what our data engineer is looking at. The top channel is logging engine rotations per minute (rpm); the second logs speed in kilometers per hour (KPH); the middle captures the throttle position; the fourth shows longitudinal G; and the bottom identifies the steering angle. The graphic also shows two examples of the lap which the car ran. Put altogether, this information helps the data engineer see what is happening in the car during the lap. It also enables the engineer to offer setup changes (or advice to the driver!) as to how to improve the overall lap time.

What Are Engineers Looking For?

Capturing the Right Data

- Engine RPM: Measured by the crank sensor, this shows whether the driver is in the best gear to get the most torque from the engine.

- Speed: A fairly obvious one to monitor, but it is crucial to watch, should the driver decide to attack the course with too much of it, which could make cornering much more challenging (see below).

- Throttle: The throttle is measured from 0 – 100% and the way the driver uses this obviously influences how the chassis, tires, and suspension must respond.

- Longitudinal G: This is an interesting choice to watch, but it only shows exactly what Peter Wright refers to his book1, as mentioned above – maximum acceleration (or deceleration) and load on the car.

- Steering angle: Is the driver sawing away at the wheel, or turning into a corner late (or early)? Is that extra speed into the corner causing the driver to apply more steering (understeer) to compensate?

Bringing it together – For the Win

Data becomes useful when all the pieces of this jigsaw come together. When it enables the team to learn a lot about the driver and the way the race car responds. As always, the answer to going faster will be a combination of factors, but the driver needs to be very aware of their part in this challenge as well as the setup of the race car.

Think about the ride height sensor, as an example. This is often infrared and unsurprisingly, measures the distance between the bottom of the race car to the surface of the track. If the race car is too high, it allows too much air to flow under the race car, making the aerodynamics less efficient, and the race car much more unpredictable to drive. If the race car is too low, it hits the track all the time, which is not only very uncomfortable, but also makes the race car act like a toboggan and go straight on instead of following the steering inputs. Our race engineer will have a pretty good idea of the optimum ride height, but a lap or two with fuel on the race car will show where those pesky new bumps have appeared since last year’s race and the height will have to be optimized to cope. Minor scraping on the ground, at the end of a straight (where we have maximum aero load), is generally okay, but more important this means the expensive racing machine will handle like a shopping trolley for the majority of the lap.

Data-Driven Performance

In today’s high-performance race car, on tracks of all types worldwide, data is proving to be the key to winning, and as more computing power is needed, smaller sensors are emerging which can perform multiple functions and lightweight connectors and cable become more prevalent. The result is changing how teams compete in motorsport. So the next time you see the race engineers staring intently at a screen (and missing the live action on the track), you will be able to understand why what they do is so critical to what is happening on the track and how their work is playing a crucial role to helping the driver win on the track.