DIP socket products for reliable connections

DIP sockets and HOLTITE sockets can provide a reliable connection between integrated circuit devices and printed circuit boards. The HOTLITE socket contact is designed as a press-fit solution with the plated through-hole of a printed wiring board. For DIP package components, the HOLTITE socket contacts on reel have disposable terminal carriers that can be peeled away and disposed of after assembly. TE’s DIP socket family includes HOLTITE socket contacts (discrete), and HOLTITE socket contacts (DIP pattern reels).

Available from 1 to 48 contacts, our DIP sockets provide a reliable connection between integrated circuit (IC) devices and PCBs. Termination options may include through hole and surface mounting, four-finger and dual leaf contacts, as well as a variety of plating options.

Product Features

DIP Sockets

- HOLTITE socket (solderless zero profile) is available

- Precision four-finger inner contacts or dual leaf contacts are optional

- Open frame and closed frame housings

IC-to-Socket-to-Board

Four-Fingered Contacts

Precision machined or stamped four-finger inner contacts with open or closed frame housings facilitate highly reliable DIP sockets.

Dual Leaf Contacts

Dual leaf contacts provide a cost effective solution to the DIP socket design with superior handling characteristics.

-140x140.jpg)

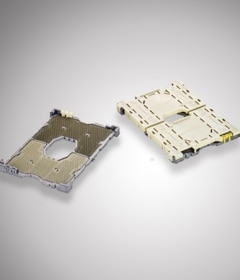

Zero Profile(HOLTITE)

HOLTITE socket contact is designed to be press-fit into the plated-thru hole of a printed wiring board, offering the solderless zero profile by allowing the plated-thru hole to become the component socket. For DIP package components, the HOLTITE socket contacts on reel provide with disposable terminal carriers, which can be peeled away and disposed after assembly.