-

Login/RegisterHi, GivenNameMy AccountLogin AgainCreate an AccountRegister to enjoy these benefits!

- Order Samples

- Track Your Orders

- Save Product List

- Access Additional Resources

- Get Tech Updates

Welcome!- Online Order Status

- Track Order History

- Samples Order History

- Check Order Status

- Request Secure Access

- My Parts List

- Recently Purchased

Manage AccountLogin to access your orders, address book, product lists, and more.

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Login/Register

- Track Your Order

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

- Products

- Industries

- Tools & Resources

- Shop TE Store

- Services & Trainings

- About TE

- Sustainability

- Cart (0)

- Hi, GivenName (Log out)

- Dashboard

- Your Account

- Track Your Order

- Recently Purchased

-

- We are here to help!

- Get in touch with our product experts.

- Chat

- Email us

This product is not currently available. For more information, including distributor inventory, please contact us.

-

Overview

This product is not currently available. For more information, including distributor inventory, please contact us.

Oil Property Sensor

- MEAS

- MEAS FPS2800

Available from

Build and price the product now

Overview

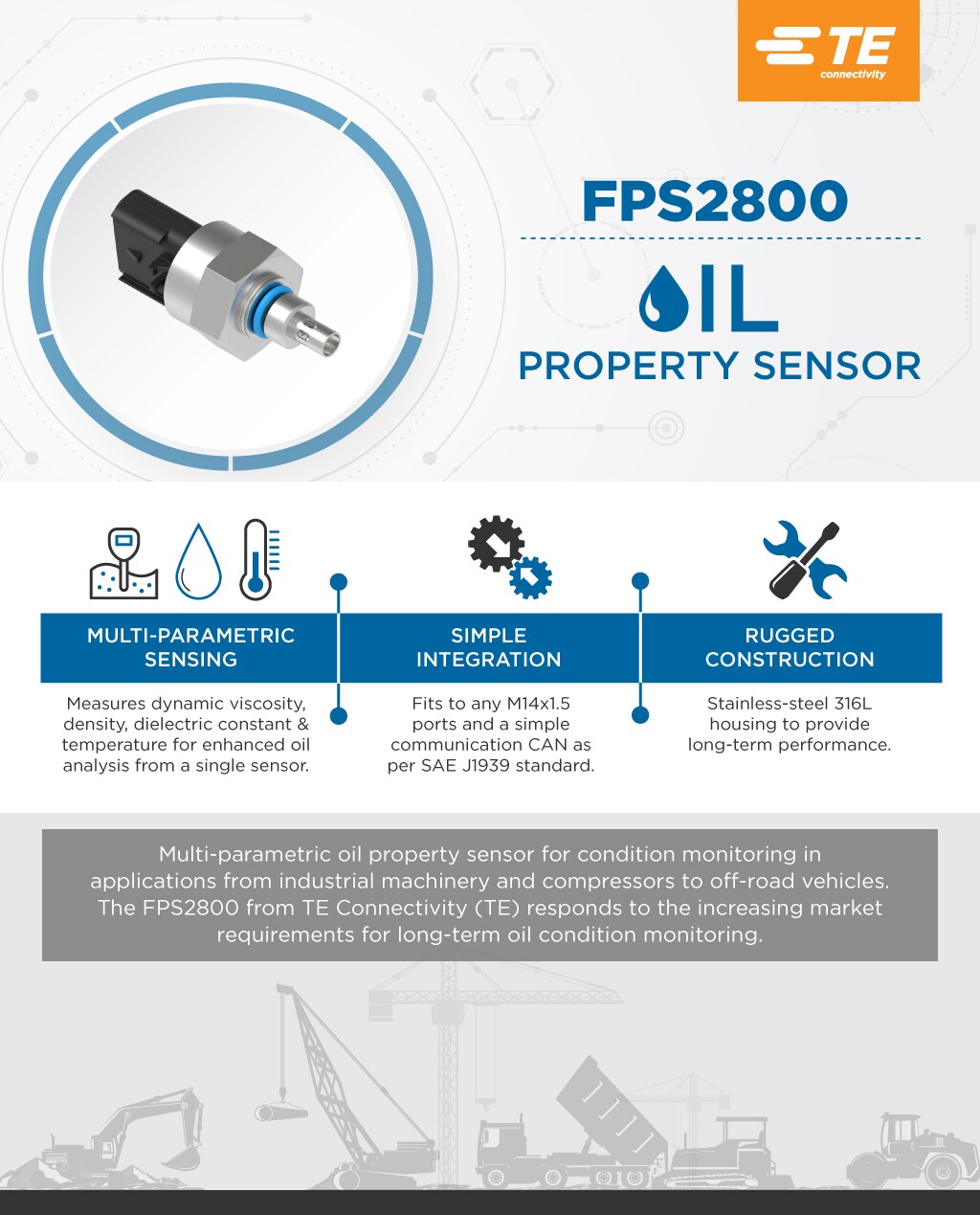

The FPS2800 is a multi-parametric oil property sensor for fluid condition monitoring in applications from industrial machinery and compressor to off-road vehicles.

25BAR

Operating Pressure

150°C

Maximum Operating and Storage Temperature (°C)

Relying on innovative tuning fork technology, the sensor monitors the direct and dynamic relationship between multiple physical properties to determine the quality, condition and contaminant loading of fluids such as engine oil, fuel, transmission and brake fluid, hydraulic and gear oils, refrigerants and solvents. The multi-parametric analysis capability improves fluid characterization algorithms. The FPS provides in-line monitoring of fluids for a wide range of OEM and aftermarket installations including fluid reservoirs, process lines and pressurized high flow conduits (e.g., engine oil gallery) for applications that include on and off -road vehicles, HVACR, compressors, industrial equipment and turbines. A universal digital CAN J1939 compliant protocol provides easy to connect interface to main Host controller. A simple 4 pin connector allows for cost effective mounting options.

J1939

Available CAN output

2.0B

Available CAN output

Benefits

- Rugged construction for high pressure and high flow environments

- Proprietary corrosion and contaminant resistant coating for wetted parts

- On-board microprocessor for real-time data analysis with 12 - 24 volts supply

- Highly reliable and long term stability

Applications

- On and Off-road Vehicles

- HVACR

- Compressors

- Industrial equipment

- Turbines

Additional Assets

-

Installation Guide

How to install the FPS2800 (English)

-

White Paper

Engine Oil Condition Monitoring with FPS2800 Oil Property Sensor (English)

-

Infographic

FPS2800 Oil Property Sensor (English)

FAQ

- What is the sensing principle ?

The FPS2800 from TE Connectivity (TE) relies on a Tuning Fork technology, a piezo-electric resonator that vibrates when a high frequency current is applied. The vibration creates, by reaction, an impedance that the sensor is able to measure. The impedance curve obtained after sweeping the current's frequency depends on oil characteristics and thanks to an equivalent model of the sensing element the sensor is able to retrieve the Dynamic Viscosity, the Density and the Dielectric constant. The sensor also provides temperature measurement acquired via a simple RTD.

- What are the measurements ranges of FPS2800 ?

TE Connectivity's oil property sensor FPS2800 measurement ranges are as following: Dynamic Viscosity: 0.5 .. 50cP (centiPoise) Density: 0.65 .. 1.5 gm/cc (kg/m3) Dielectric Constant: 1 .. 6 Temperature: -40 .. 150°C All oil characteristics shall be within the specified ranges at the same time to ensure a proper measurement.

- What are the available power supply options ?

FPS2800 is compatible with 12V or 24V power supply, hence it will function properly for voltages ranging from 9V to 36V. The associated current will not exceed 100mA.

- What is the communication protocol available on oil property sensor ?

The TE's FPS2800 oil property sensor provides CAN output as per SAE J1939 standard.

- What is the maximum operating pressure of the TE Connectivity Oil Property Sensor ?

The FPS2800 is qualified for pressurized areas up to 25 bar.

- How to best mount my FPS2800 ?

TE Connectivity recommends to install the sensor in a pressurized area on the clean side of the systems (after the filter). Dead ends and oil pans should be avoided and some minimal oil flow is preferred to ensure temperature homogeneity. To avoid creating parasitic noise on the measurement it is recommended to verify that the voltage difference between the electrical ground of the sensor and the stainless steel body is null. For further information, read the installation guide.

- On which application /system can I install the FPS2800 ?

The oil property sensor can be installed on any application/system using oil which characteristics are within the specified ranges. This goes from On and Off Higway vehicles (trucks, construction equipment, agriculture vehicles) as well as Industrial equipment such as compressors, industrial hydraulic machines, generators, etc.

- How can I determine when to change the oil ?

Based on FPS2800 outputs, user must determine algorithm(s) that best suit his system, his application. To get some guidance, please have a look to the TE Connectivity White Paper to learn more.

- Can the FPS2800 sensor provide other outputs ?

The standard version provides the dynamic viscosity, density, dielectric constant and temperature. For evaluation purpose only, TE Connectivity can provide one additionnal input, called Rp, being an image of the oil resistivity.

- Is there any maintenance needed for FPS2800 ?

No. If installation location respects the recommendations from TE Connectivity then no maintenance is required on the FPS2800 oil property sensor.

Features

Please review product documents or contact us for the latest agency approval information.

Detailed product features are not currently available online.

Related Materials

CAD Files

- 3D PDF pdf 3D

- Customer View Model 2d_dxf.zip English

- Customer View Model 3d_igs.zip English

- Customer View Model 3d_stp.zip English

Datasheets & Catalog Pages

- FPS2800B12C4 pdf English

Brochure

- Industrial and Commercial Transportation Sensor Solutions (English) Learn more about our sensor solutions for industrial and commercial transportation applications. German

Are you sure you want to close chat?

Chat

To begin your chat with TE please enter your details