Transferring Your Microfluidic IVD Consumable Design to Full-Scale Manufacturing

In the previous entries in this blog series Understanding User Requirements and Testing High-Risk Features Through Couponing we’ve discussed the steps inherent in conceiving, designing, prototyping, and testing your new IVD product. Though we’ve more or less presented them as individual steps, they are actually part of a fluid and iterative whole. Insights from each step of the process lead to revision and tweaking of the prior step’s results.

Ultimately, these separate elements are integrated into a well-understood product design with defined specifications and tolerances for each component that have been validated through rigorous testing. Experienced oversight of this integration process is essential for transfer to full-scale manufacturing.

Moving from Full IVD Prototype Testing Into Integration

Completion of the couponing and full prototype testing stages triggers the integration process. Much of what is learned in the development stages can be qualitative in nature. Integration looks back at those lessons (as well as lessons learned during couponing) to quantitatively characterize component performance.

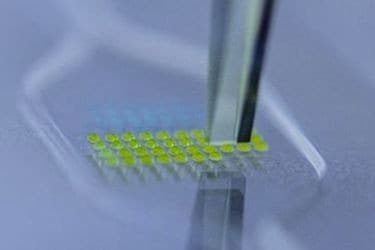

Breadboarding, a process used to verify the product’s electromechanical system and circuit performance; provide an interface analysis and test the robustness of components. These testing activities, along with the evaluation of assembly and process parameters, reveal the critical features necessary to achieve product performance and meet user requirements. Only by vetting the design, process, and interfaces can an integrated design remain on a rapid development timeline. If all critical features aren’t identified properly at the start, or if a thorough evaluation of each isn’t performed, it can severely affect pre-projected timelines. A late-stage discovery of faults or weaknesses in one of the product’s critical features can trigger a cascade of other problems and cause consequential delays. If that feature or product component needs to be redesigned, retesting will be necessary both individually and as part of the whole integrated system. This spillover effect tends to produce cost overruns and derail project dates.

The interdependency of product components and the steps in the development, prototyping, and testing process underscore the value of two other crucial elements in a rapid-development timeline: documentation and project managers.

Documentation of each step of the development process is fundamental. It is a prerequisite of the design-control framework for FDA-regulated products. It creates a record of the project’s overall objectives, the assumptions prior to each stage, the actions taken, the raw materials used, the evaluations performed, and the results. The documentation of one phase leads to an improved set of assumptions that lay the groundwork for each of the steps in the next phase. Sometimes, it slightly revises objectives, particularly after a close look at user requirements. Documentation is the raw material of the integration process.

Proven Expertise, From Concept to Market

Project Management Essential for Transfer to Manufacturing

Project managers are the secret weapon in meeting rapid development timelines. This role essentially integrates the learnings in real-time by understanding the overall objectives, assumptions, prescribed steps, and testing approaches. This effectively adjudicates the lessons of each stage to interpret the impact on the overall plan. Of course, the whole team is involved with interpretation; however, the project manager’s role is to take a holistic view of the priorities in the development of the product. Project managers act to represent the customer, the manufacturer, and everyone downstream who relies on a well-executed design and manufacturing plan to result in a high-quality product.

Companies carefully assess and assign project managers based on the needs of the project, the skill sets required, and the workloads of various key team members. It is certainly common for the “lead engineer” on a project to also be the project manager. For products expected to use a new manufacturing approach, a leader from the manufacturing function may join the team very early on and support the project manager due to their proficiency with translating design-stage products to full-scale manufacturing. For products expected to bring the company into a new market niche or breakthrough in its existing market, a technology-savvy marketing leader will support the product manager.

Choose Your Development and Manufacturing Partner Carefully

Most “diagnostics manufacturers” are the responsible parties behind the product’s application for approval and eventual distribution to the market, even though they use contract manufacturing for some or all of the physical product. In other words, an IVD manufacturer by FDA definition is not necessarily the organization which physically creates the final product.

Choosing a contract manufacturer (CM) lays the groundwork for a long-term partnership rather than a simple vendor transaction. Stability in manufacturing processes and facilities is highly valued by the FDA, and essential for cleared and approved products. The CM will put key elements of your plan into action and bring your vision to life. With this partnership perspective, potential CMs must also meet the criteria of speed-to-market and high-quality work.

Your company will want to consider several possible CMs by understanding their standard capabilities, areas of focus, prior successes, and reputation with existing customers. Often, these characteristics can be assessed through online research, video conferences with candidate partners, written self-evaluations, and calls with their customers. You can narrow the field to two or three possibilities without even entering their buildings.

The final cohort of candidates will then need to be subjected to a much more rigorous evaluation. Your whole team should be involved in devising the assessment plan and audit, which reflects standard GMP, QA/QC, and ISO considerations, as well as the specific manufacturing capabilities necessary to address each of the critical features identified in the prototyping, testing, and couponing process. After an onsite audit of each candidate company’s manufacturing facilities determines all your needs will be met, the team should also consider the quality of intercompany communication they’ve been able to achieve. Given the long-term nature of the partnership, don’t settle for anything less than open and cooperative relationships among individuals at all levels, from front-line operators to engineers and corporate executives.

In addition to the primary CM making the final product, other product-related partners (including the third-party material suppliers, instrument development companies and component manufacturers) should be subject to a similar process. You may not need to consider as many candidates—in fact, in some specialty manufacturing situations you won’t be able to find as many—but the rigor of the process should be upheld, perhaps with a smaller internal team evaluating each category.

Transfer to Contract Manufacturer for Scale Up

Having selected your contract manufacturing partner, component manufacturers, third-party raw material suppliers, and instrument development collaborators, the next step is to transfer your production process to the CM for scale up and manufacturing. This can be one of the most difficult processes because it requires the new CM and the client to share an in-depth understanding of the detailed learnings accrued over months of development. A true handoff is more than just a data dump—it relies upon the extensive documentation captured throughout the process, the relationships developed, and communication methods. This includes the relationships within the team at the client company, those among the various functions at the CM company, and those between client and CM employees.

Manufacturing departments often complain about how R&D functions do not provide sufficient information or understanding about the product at transfer. Yet manufacturing becomes responsible for verification and validation builds, process improvements, cost management, supplier and partner management, and environmental controls. These tensions can be anticipated and prevented with in-depth discussions during the manufacturing-candidate assessment process and planned for during the contracting process. In fact, using the assessment plan designed by the R&D team for candidate selection is a great way to reduce the conflicts that sometimes arise once full-scale manufacturing begins. Continued involvement of a product champion throughout the assessment phase, contract negotiations, and early phases of transfer and scale-up are other ways to ensure that the full benefit of the development team’s learnings are applied to optimize quality manufacturing of the end product.

Start with the end in mind

As you develop your consumable IVD device, ensuring the creation of a high-quality product with a reduced time-to-market requires thoughtful planning, team building, and execution of a product plan. That product plan ultimately incorporates three key phases: understanding user requirements; the art of couponing; and integration and transfer to full-scale manufacturing. Once your company has clearly identified the unmet needs your product will address and the key technology or design features that will differentiate it, choosing a development partner who can guide you through this multi-part process can make all the difference in achieving the targets you’ve set.