Trend Insight

A 3D solution for a growing challenge

In a bid to satisfy continually increasing demands for higher performance, communications equipment providers are moving to higher speeds on their internal printed circuit boards (PCBs). 28Gbps signal rates are now in design phases, with 56Gbps and 112Gbps rates in the future.

The challenge is that PCBs are not well suited to handling these higher speeds – they have issues with signal integrity (noise, insertion loss, amplitude, etc.), and that limits the distance PCB traces can reliably carry a high-speed signal. As a result, PCB designers must cope with board layout limitations or move to higher-performing but more expensive PCB materials.

Mid-board copper (MBCu) solutions use connectors and cable assemblies to address this challenge. By bypassing the PCB, an MBCu solution delivers greater design flexibility, lower costs, and much better signal integrity performance. With a cable that can extend to any component inside the box or even to external devices outside the box, an MBCu connectivity solution turns a two-dimensional circuit board design into a 3D space where far more configurations are possible.

Let’s look at some of the design considerations for specifying mid-board copper solutions.

"An MBCu solution turns a two-dimensional circuit board design into a 3D space where far more configurations are possible."

Design Considerations

There are several criteria designers should think through when considering a mid-board copper solution, including flexibility, signal rate, insertion loss, distance, connector configuration, and cable type.

Flexibility

Connector Standards

Designers have to deal with nearly 30 different connector standards, including PCIe, SAS, SATA, Ethernet, and InfiniBand. It’s painful to consider using a different connector for each standard, but this has been the practice until recently. Now, it’s possible to use one connector design to support all standards. To meet this requirement, the MBCu solution should:

- Work across a range of data rates, from 8Gbps to 112Gbps

- Use standard manufacturing processes

- Offer both vertical and horizontal connection options

- Offer a range of pin configuration options to address all design needs

- Accept a cable connection to take the connector from a 2D to a 3D solution that allows flexible connectivity to components and devices both inside and outside the box

- Be cost-effective enough for lower-performance applications yet high-performance enough for higher-speed applications

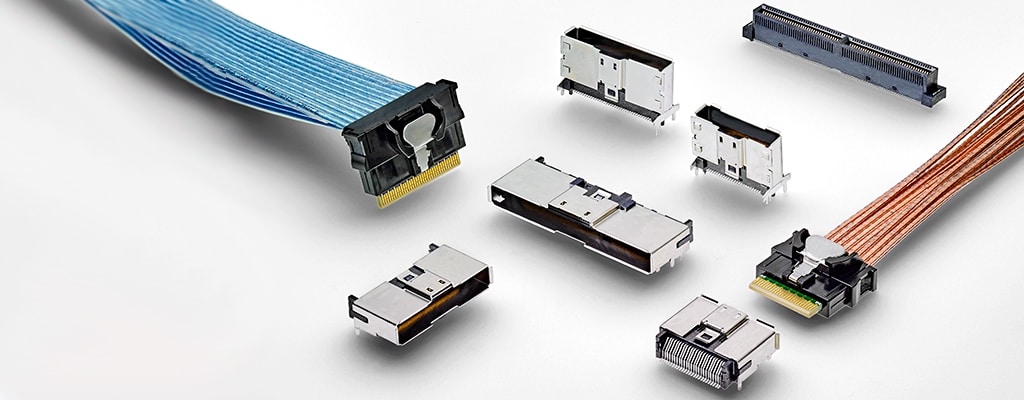

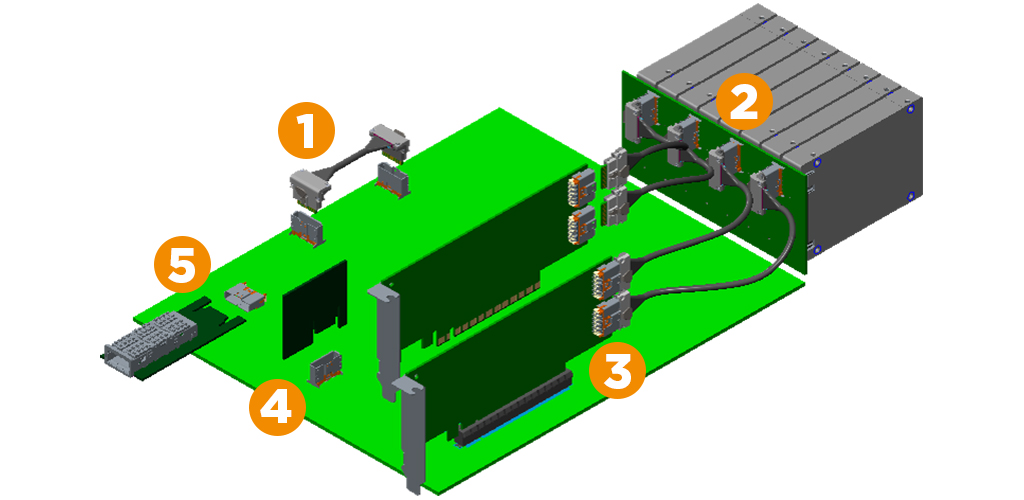

MBCu solutions are being applied in a variety of designs. TE's Sliver Interconnects is one technology solution that enables multiple new designs including 1) mid-board cable applications, 2) backplane/mid-plane applications, 3) low-profile PCIe add-in card applications, 4) vertical card edge applications, and 5) horizontal card edge applications.

Signal Rate

MBCu Solutions

While PCBs may be fine for transporting signals up to 10Gbps, they begin to limit performance at higher speeds. Designers can use MBCu solutions to increase their HPC capabilities because they can put a connector right next to a processor and drive signal as fast as the IC can handle. With this solution, the PCB is no longer a bottleneck to performance.

Insertion Loss and Signal Integrity

Quick and Reliable

Designers can only put up with so much insertion loss before the PCB traces have to get really short – less than four inches to go from a connector to an IC. A mid-board copper solution eliminates this restriction because you can use a cable to take signal quickly and reliably as far as you need to take it.

Whenever you are routing signals through traces on a PCB, there are a lot of traces. When you’re routing the traces through all of the components, you have to be cognizant of the signal integrity, and you need to do extra signal integrity analysis to ensure proper performance. When you use a cable you eliminate signal integrity issues.

Distance

Signal Reach

MBCu solutions come with various gauge cables, but all deliver signals over greater distances than PCBs. For example, a 33-gauge cable typically delivers a 4X savings in insertion loss; with larger cables (30-gauge or lower), the insertion loss improvement will be even better. As a result, a design that enforced a limit of four inches using a PCB can now extend 16 inches using an MBCu with a 33-gauge cable. This promotes design flexibility and simplifies the PCB layout.

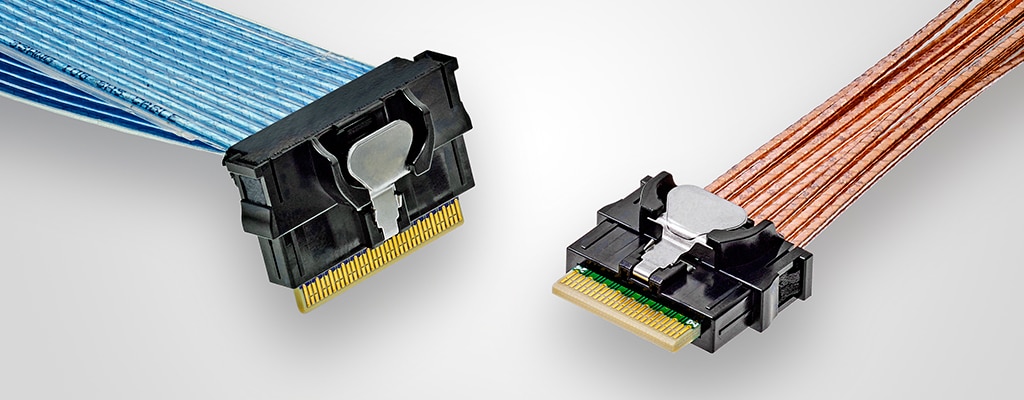

Sliver interconnect system, TE's leading MBCu solution, offers ribbon cable and TwinAx cable assemblies for greater design flexibility.

Cable Type

MBCu Solutions

MBCu solutions should offer a choice of cable types: ribbon cable or Twinax. Ribbon cable is used for lower-speed applications like PCIe or SAS, but if the design requires a 28Gbps or higher-speed signal, it will most likely employ a discrete Twinax cable.

Connector Configuration

PCB Technology

In a solution with a .6mm pitch, the plug-in card that goes into it uses standard PCB technology. When you go to a MBCu product with a .5mm pitch, you can’t use current PCB technology that’s typical to the industry: you either have to use a two-piece connector, or you have to go to BGA (Ball Grid Array) laminates that are used for very tight applications and are more expensive. Also, you should decide whether you need vertical or right angle connectors – this will depend on the application. A solution that offers both vertical and right angle connectors will give you more flexibility.

Advantages of Mid-Board Copper Solutions

What do the flexibility and cost savings of an MBCu solution provide? They offer a unified, high-performance platform to use for a variety of interconnects in a system. Rather than using one connection for a card edge and another connection for a cable and a third for a socket, designers have one platform that can be used in multiple places. This helps simplify and streamline the qualification and design processes. In addition, MBCus offer a cost-effective alternative to optical connections: an optical module might cost 6-7 times more than MBCu cabled solutions.

As equipment makers move to higher speeds on their PCBs, MBCu solutions are becoming an attractive alternative for carrying signal within a system, delivering greater design flexibility, higher performance, and lower costs. By selecting an MBCu solution that meets all applications, manufacturers can save design time and costs.