Easily-assembled

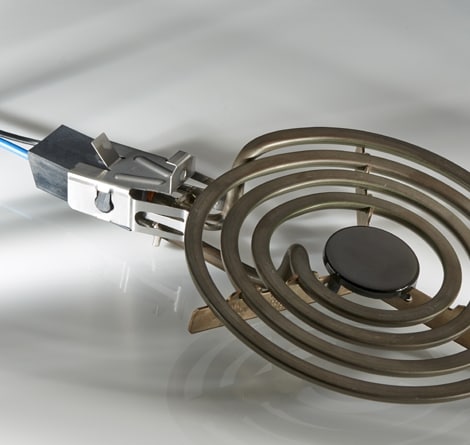

Surface burner connector system comprises a high temperature housing, plug-in receptacles and multiple clip offerings. TE’s new housing offers an improved, cost-effective solution for applications using a traditional coil-type, plug-in heating element.

Easily- assembled surface burner connector system comprises a high temperature housing, plug-in receptacles and multiple clip offerings. TE’s new housing offers an improved, cost-effective solution for applications using a traditional coil-type, plug-in heating element. The new housing is approved to 240°C, a higher emperature than competitive solutions. Additionally, the new licquid crystal polymer (LCP) housing from TE is less prone to chipping and cracking than competing housings molded from other materials. Receptacle design permits the use of high-speed equipment to terminate leads. Clips are available in multiple configurations to satisfy various range and burner designs. The system facilitates changing burner elements and tests demonstrate these robust connector systems still operate after 3500 cycles of mating and unmating. The connector system is UL recognized and CSA certified.

Key Features

- High temperature matieral withstands temperatures up to 240°C, higher than competitive products

- Side retention ears on the housing allow it to easily be snapped into clips of various configurations to satisfy multiple design requirements

- Utilizes a receptacle terminal with a proven track record, having been successfully used by

OEMs for several years

Applications

- Primary applications are anticipated in freestanding or slide-in electric ranges and drop-in cooktops using coil-type surface burners for the North American market.

- Other applications may be found in small appliances such as portable countertop electric hot plates using coil-type surface burners.