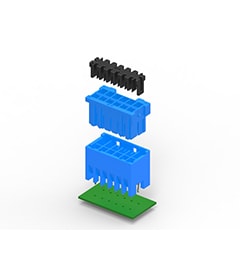

Solutions for Easy Assembly in Tight Spaces

Compact Economy Power 2.5 (EP 2.5) connectors are designed for easy assembly of space limited low power and signal systems. The connectors feature polarization tabs to prevent post misalignment, audible positive latching to ensure complete mating, and low insertion force (LIF) contacts for ergonomic assembly. Additional EP 2.5 product options further simplify the assembly process, including packaging to support automated board assembly and terminal position assurance (TPA) devices to secure contacts in a mated position. The EP 2.5 connector family supports wire-to-wire and wire-to-board systems with both single row and dual row configurations and is designed to be intermateable with similar 2.5mm pitch connectors for retrofit applications.

Product Features

| Centerline (mm) | 2.5 | Operating Temperature (°C) | -55 to +105 |

| Maximum Current Rating (A) | 4.2 | Wire Size (AWG) | 26-20 |

| Voltage Rating | 250 VAC | Positions Available | 2-40 |

| IEC 60335-1 Glow-Wire Available | Yes | Sealed Version Available | No |

| UL94 Rating Available | V-0 | Color/Keying Available | Yes |

| Agency Approvals | UL, VDE | Available Configurations | Wire-to-Wire, Wire-to-Board |

Featured Products

Economy Power 2.5 Surface Mount Headers

Economy Power 2.5 (EP 2.5) surface mount technology (SMT) headers are designed to help you incorporate automated processes into your printed circuit board (PCB) assembly. As compared to traditional through hole PCB headers, EP 2.5 SMT headers are better suited for automated pick-and-place assembly, require fewer processing steps, and support more efficient reflow soldering.

Economy Power 2.5 Headers on Tape in Ammo Box

To better meet the needs of high volume manufacturers with automated assembly processes, TE now offers EP 2.5 headers on tape in ammo box packaging. These headers are available in 2-8 positions and in various colors.

Low Insertion Force (LIF) Socket Contacts for EP 2.5

EP 2.5 socket contacts are now available with low insertion force (LIF). These LIF contacts have a maximum insertion force of 3.5N, as compared to 8.9N for the standard contacts.